Equipment and method for collecting nanoparticles in grading manner

A nanoparticle and equipment technology, which is applied in the equipment and field of classifying and collecting nanoparticles, can solve the problems of low yield, uneven particle size, complicated process control, etc., and achieve the effect of high yield, uniform particle size classification, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

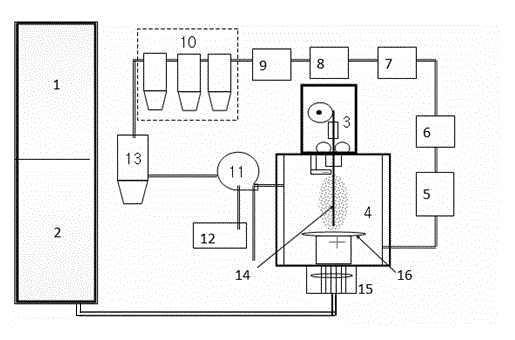

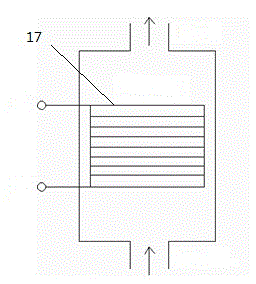

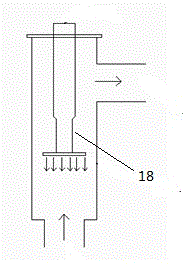

[0053] see Figure 3 to Figure 7 , the equipment for classifying and collecting nanoparticles includes an ultrasonic dispersing device 7 connected in sequence by pipelines, a degaussing device 8, an automatic airflow control device 9 and a classifying collection system 10; an ultrasonic generator 18 is provided in the ultrasonic dispersing device 7; The degaussing device 8 is provided with an alternating magnetic field composed of two degaussing plates 19; the airflow inlet end of the airflow automatic control device 9 is provided with a wind speed sensor 20, and the airflow outlet end is provided with a valve connected to the damper controller 21. Damper; the classification collection system 10 includes a plurality of collectors, the top of the collector is provided with an air inlet and outlet device, and one side of the air inlet and outlet device is provided with an air intake pipe along the tangential direction of the collector port, and the top of the air inlet and outlet...

Embodiment 2

[0055] 1. Silk

[0056] According to the needs of the obtained metal nanoparticles, select high-purity suitable material metal wires, the purity of which can reach more than 95%, the length of which is 8-12 cm, and the diameter is 0.1-0.8 mm.

[0057] Install the metal wire 14 in the wire feeding device 3 , and send the metal wire into the reaction chamber 4 by rolling the upper and lower rollers in the wire feeding device 3 . Use the button to adjust the position of the wire to align with the electrode plate 16 and balance the distance between the wire and the electrode plate 16, seal the reaction chamber 4, and adjust the voltage of the high voltage to be between 25-45KV.

[0058] 2. Filling with protective gas

[0059] First turn on the vacuum pump 12 in the reaction system to evacuate the entire system to create a vacuum environment, then turn off the vacuum pump, and use the blower 11 to fill the system with protective gas until the air pressure is 1×10 ~1×10 Pa....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com