Polybetaine fluorescent labeling agent and preparation method thereof

A fluorescent labeling and betaine technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of complicated purification processing, low labeling efficiency, expensive raw materials, etc., and achieves high fluorescence brightness, environment-responsive type, and high reaction yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

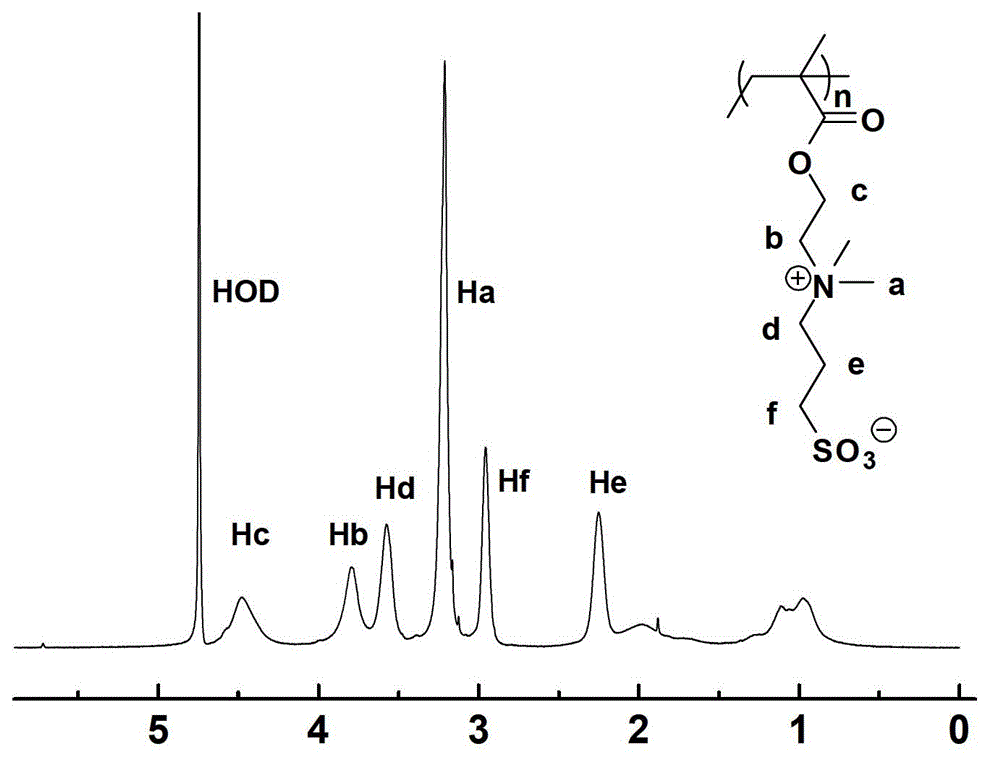

[0056] The betaine monomer is N-(3-sulfopropyl)-N-(1-methacrylic acid ethyl)-N,N-dimethylammonium, the structural formula is:

[0057]

[0058] The FR group of the copolymerized fluorescent monomer is rhodamine B, abbreviated as RB-MA, and the structural formula is:

[0059]

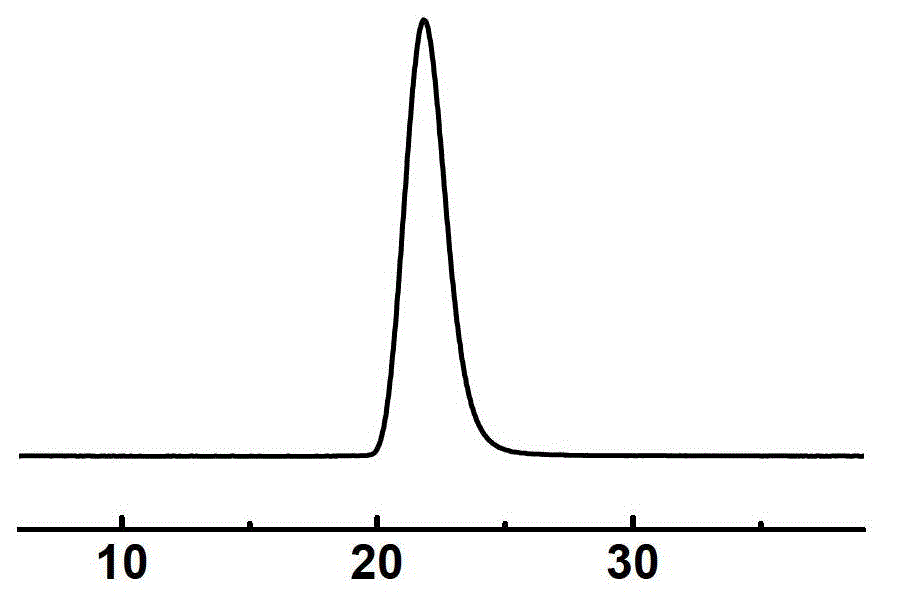

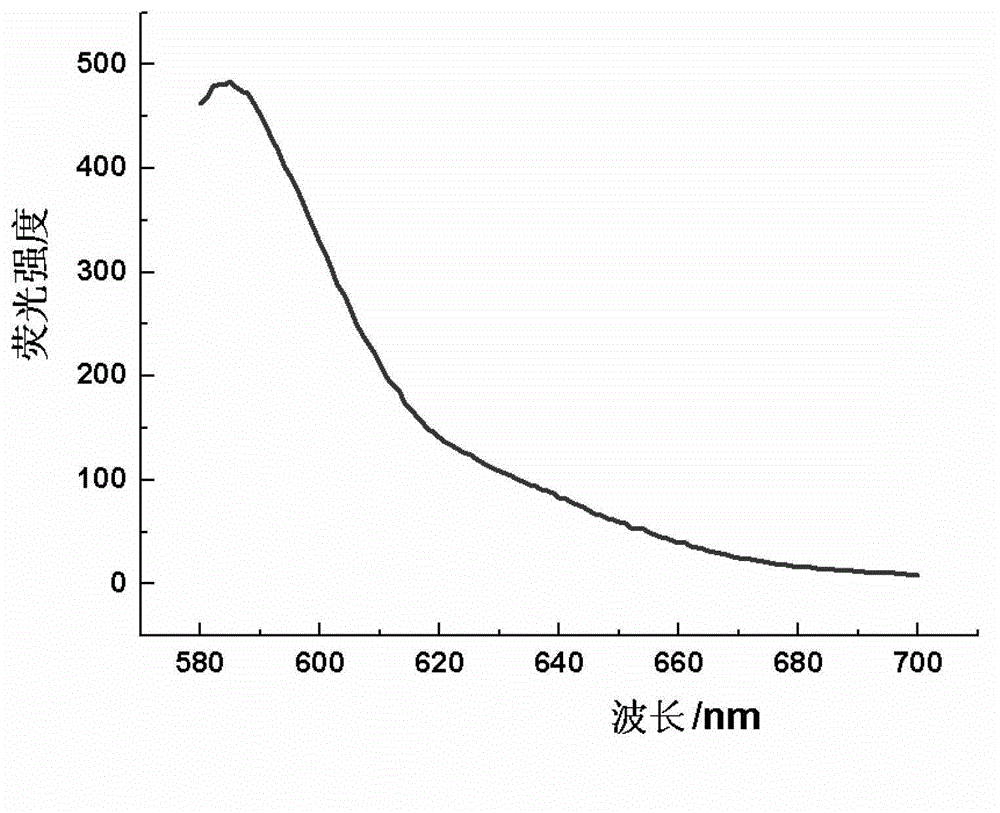

[0060] 1g of betaine monomer is dissolved in potassium dihydrogen phosphate-disodium hydrogen phosphate buffered aqueous solution with a pH of 7.0, and the monomer concentration is 0.6mol L -1 , adjust the concentration of NaBr to 0.50mol L -1 , the required amount of RB-MA, chain transfer agent (CTA, S-isocyanate-N-ethyl-N'-phenyl dithiocarbamate) and initiator (V-501, azo Dicyanovaleric acid) was dissolved in 0.5mL methanol, the two were mixed, and the reaction molar ratio was: betaine monomer: [CTA]: [V-501]: [RB-MA]=1600:1:0.2 :2.4. Liquid nitrogen was used for three freeze-thaw cycles to completely remove residual oxygen, and then the reaction was stirred at 70° C. for 10 hours; the reactio...

Embodiment 2

[0065] Betaine monomer is N-(3-sulfopropyl)-N-(1-methacrylamidoethyl)-N,N-methylammonium, the structural formula is:

[0066] The FR group of the copolymerized fluorescent monomer is rhodamine 6G, abbreviated as R6G-MA, and the structural formula is:

[0067]

[0068] 1g of betaine monomer is dissolved in potassium dihydrogen phosphate-disodium hydrogen phosphate buffer solution with a pH of 6.5, and the monomer concentration is 1.0mol L -1 , adjust the concentration of NaBr to 0.50mol L -1 , the required amount of copolymerized fluorescent monomer, chain transfer agent (CTA, S-isocyanate-N-ethyl-N'-phenyl dithiocarbamate) and initiator (V-501, even Azodicyanovaleric acid) was dissolved in 0.5mL methanol, and the two solutions were mixed, and the reaction molar ratio was: betaine monomer:[CTA]:[V-501]:copolymerized fluorescent monomer=1000:1: 0.15:2.0. Three freeze-thaw cycles with liquid nitrogen were used to completely remove residual oxygen, and then the reaction wa...

Embodiment 3

[0073] The betaine monomer is N-(3-carboxylic acid ethyl)-N-(1-methacrylic acid ethyl)-N,N-dimethylammonium, the structural formula is:

[0074]

[0075] The FR group of the copolymerized fluorescent monomer is rhodamine B, abbreviated as RB-MA, and the structural formula is:

[0076]

[0077] 1g of betaine monomer is dissolved in potassium dihydrogen phosphate-disodium hydrogen phosphate buffered aqueous solution with a pH of 7.0, and the monomer concentration is 1.0mol L -1 , adjust the concentration of NaBr to 0.50mol L -1 , the required amount of copolymerized fluorescent monomer, chain transfer agent (CTA, S-isocyanate-N-ethyl-N'-phenyl dithiocarbamate) and initiator (V-501, even Azodicyanovaleric acid) was dissolved in 0.5mL methanol, and the two solutions were mixed, and the molar ratio of the reaction feed was: betaine monomer:[CTA]:[V-501]:copolymerized fluorescent monomer=200:1: 0.25:1.0. Liquid nitrogen was used for three freeze-thaw cycles to completely re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com