Method for preparing ink solvent by utilizing waste animal and plant grease

A technology for discarded animals, plants, and oils, which is applied in the fields of oil/fat refining, ink, application, etc., and can solve problems such as poor drying performance and narrow application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

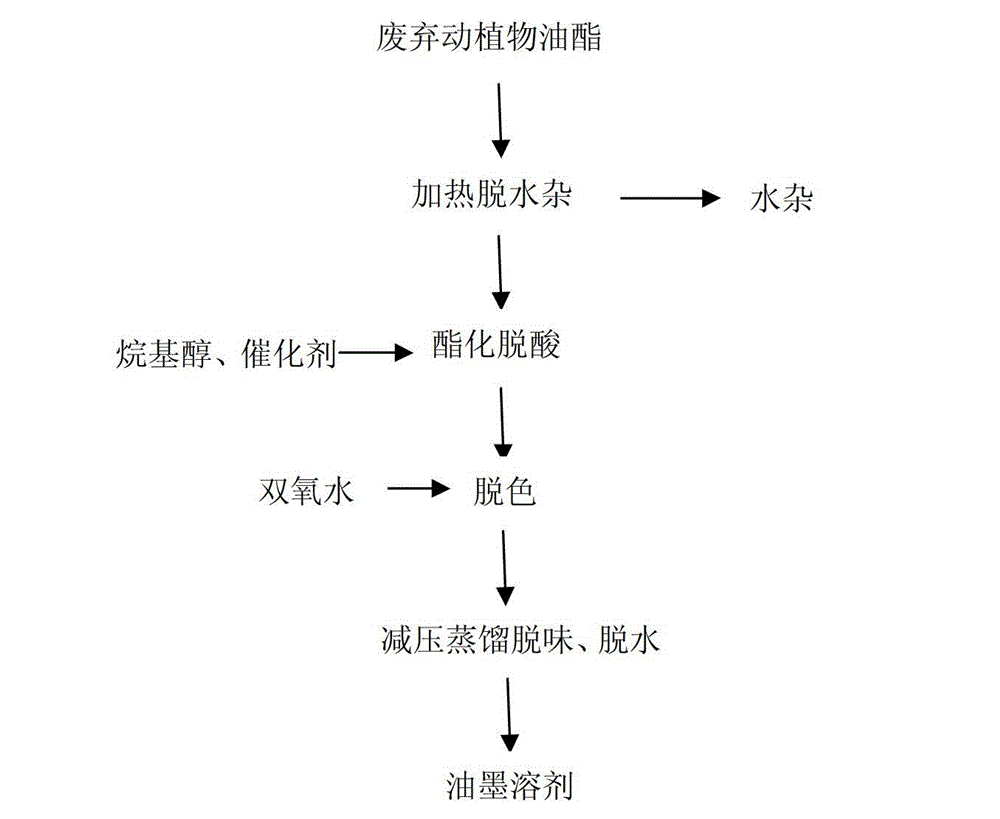

Method used

Image

Examples

Embodiment 1

[0057] 200g of waste oil after dehydration (acid value 13.6KOH / g waste oil, golden yellow in color) is added in the 500ml airtight high-pressure reactor, to which adding quality is 15% methyl alcohol of waste oil, acidic catalyst (iron sulfate: magnesium sulfate: Calcium sulfate=50:20:30) The mass is 3% of waste oil, heated to 125°C, pressure 0.4MPa, stirred rapidly for half an hour, then removed the reaction solution, distilled excess methanol and water under normal pressure, and removed the catalyst by separation , to get the supernatant, the acid value is 0.49gKOH / g waste oil;

[0058] Add 12% hydrogen peroxide with a concentration of 35% to it dropwise at 60°C, stir for 0.5 hours, stop the reaction, and separate and remove the water phase (hydrogen peroxide, water, etc.);

[0059] The product after the above reaction was distilled under reduced pressure at 80°C and -0.09MPa for 1 hour to remove moisture and odor to obtain dry and pure esterified oil.

[0060] Its physical...

Embodiment 2

[0064] Add 200 g of hogwash oil after dehydration (acid value 9.6KOH / g oil, yellow color) into a 500ml closed high-pressure reactor, add 20% ethanol whose quality is hogwash oil, acid catalyst (iron sulfate: magnesium sulfate: calcium sulfate =40:30:30) The mass is 2% (w) of hogwash oil, heated to 145°C, pressure 0.6MPa, stirred for 1 hour, then removed the reaction solution, distilled excess ethanol and water under normal pressure, and removed the catalyst by separation. Obtain the supernatant liquid, the acid value is 0.32gKOH / g hogwash oil;

[0065] Add 8% hydrogen peroxide with a concentration of 35% dropwise at 70°C, stir for 0.5 hours, stop the reaction, and separate and remove the water phase (hydrogen peroxide, water, etc.);

[0066] The product after the above reaction was distilled under reduced pressure and vacuum for 1 hour at 70°C and -0.095MPa to remove moisture and odor to obtain dry and pure esterified oil.

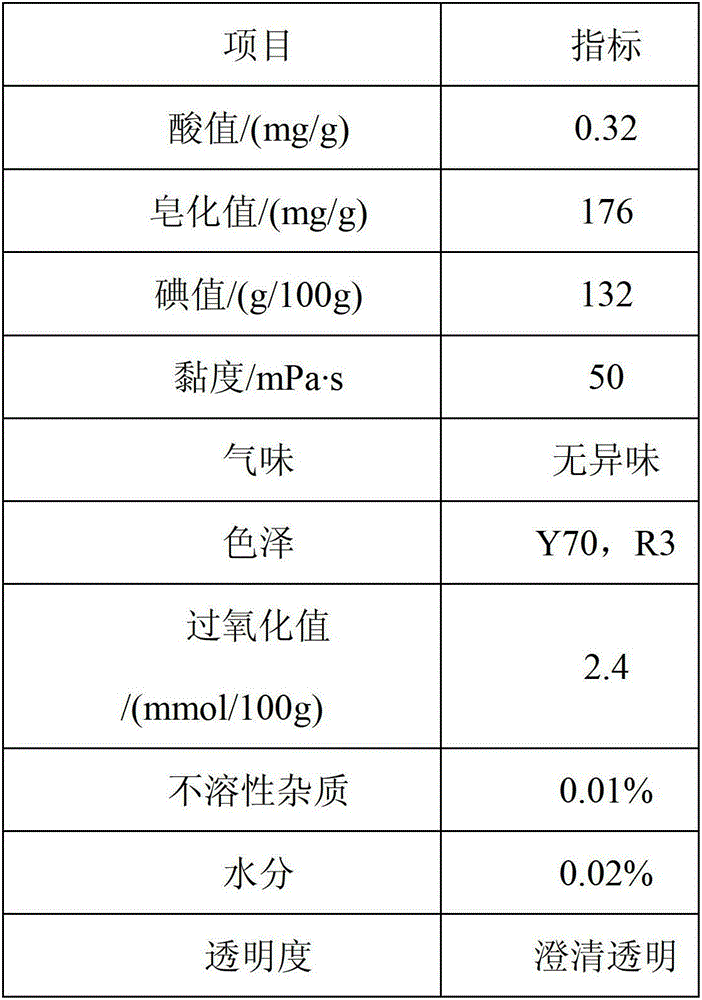

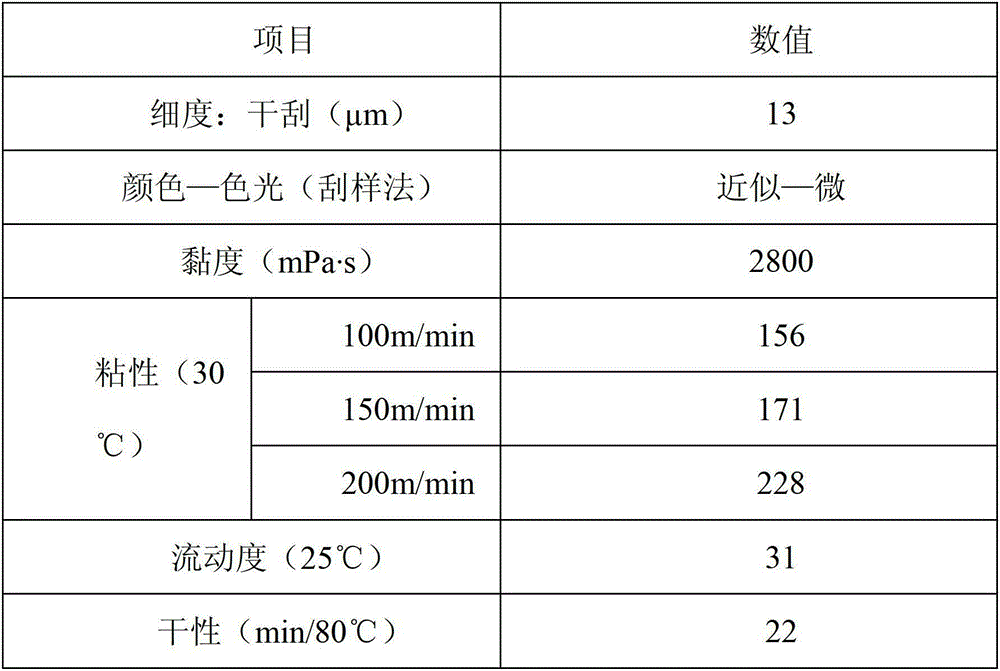

[0067] Its physical and chemical properties have be...

Embodiment 3

[0071]Add 200g of hogwash oil after dehydration (acid value 22.6KOH / g oil, color and luster yellow) in the 500ml airtight high-pressure reactor, add quality wherein to 20% butanol of hogwash oil, acid catalyst (iron sulfate: magnesium sulfate: sulfuric acid Calcium=50:30:20) The mass is 2% of hogwash oil, heated to 150°C, pressure 0.6MPa, stirred for 1 hour, then removed the reaction solution, distilled excess butanol and water under normal pressure, and removed the catalyst by separation to obtain The supernatant has an acid value of 0.45gKOH / g hogwash oil;

[0072] Add 10% hydrogen peroxide with a concentration of 35% to it dropwise at 70°C, stir for 0.5 hours, stop the reaction, and separate and remove the water phase (hydrogen peroxide, water, etc.);

[0073] The product after the above reaction was distilled under reduced pressure and vacuum for 1 hour at 80°C and -0.095MPa to remove moisture and odor to obtain dry and pure esterified oil.

[0074] Its physical and chemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com