Immersion type fluid analytical device and debugging method thereof

A technology of fluid analysis and analysis equipment, applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve the problems of inconvenient production and maintenance, increase production cost, device dispersion, etc., to prevent collision damage or accident The effect of downtime, low cost, compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

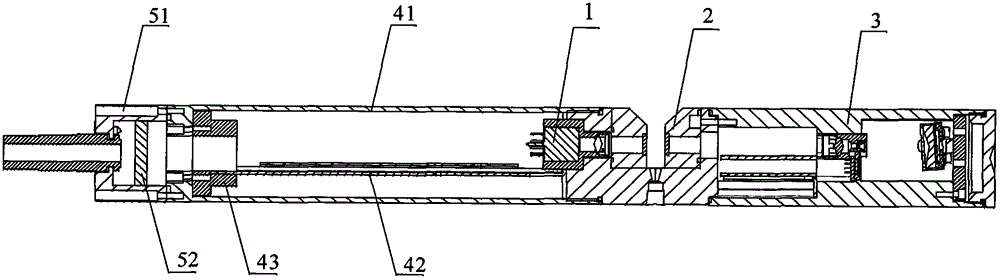

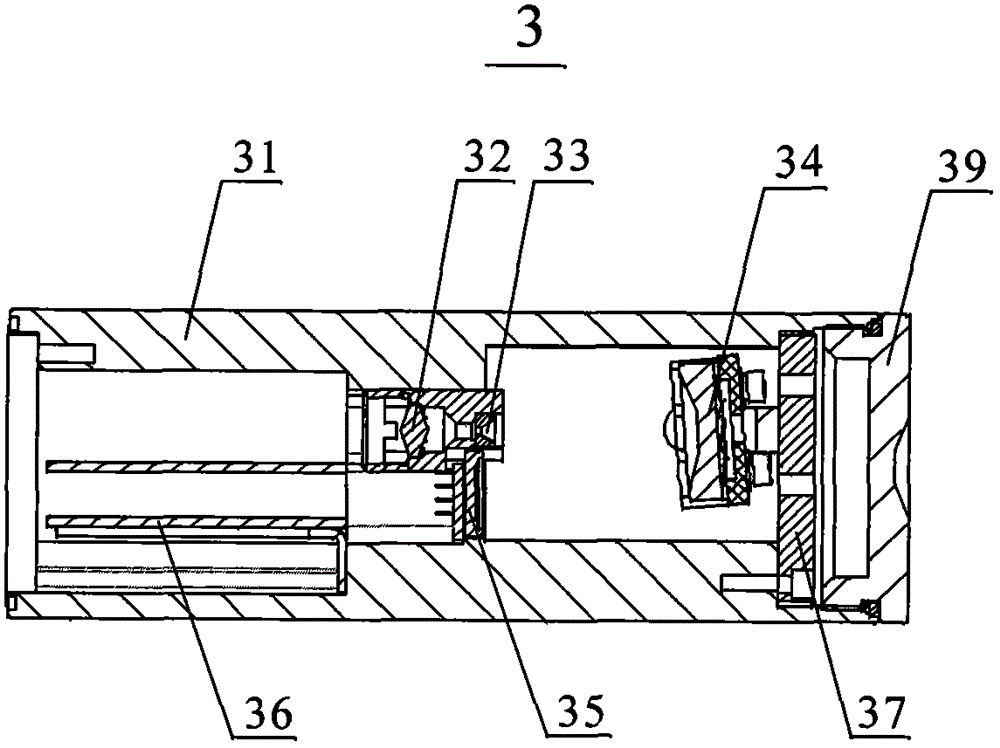

[0052] figure 1 The basic structural diagram of the immersion fluid analysis equipment of the embodiment of the present invention is schematically given, as figure 1 As shown, the immersion fluid analysis equipment includes

[0053] A light source 1, the light emitted by the light source 1 has measurement light corresponding to the absorption spectrum line of the fluid to be measured; such as xenon lamp, deuterium lamp and other broad-spectrum light sources.

[0054] A measuring pool 2, the measuring pool is located between the light source and the optical module, and is used to contain the fluid to be measured when immersed;

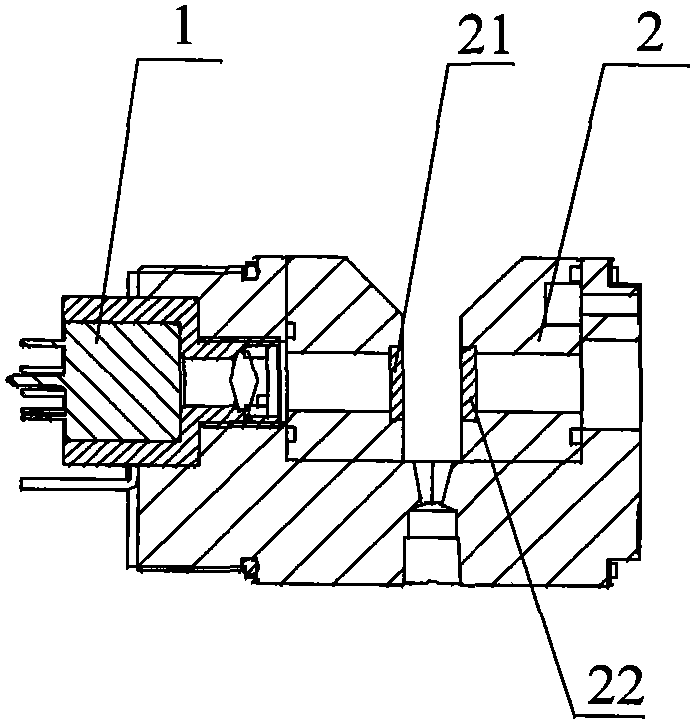

[0055] figure 2 The basic structural diagram of the preferred measuring cell of the embodiment of the present invention is schematically given, as figure 2 As shown, the measuring cell 2 is in a "concave" shape and has optical windows 21, 22. There is a free space between the optical windows 21, 22. The fluid to be measured enters the free space, and...

Embodiment 2

[0079] According to the application example of the fluid analysis equipment and its debugging method described in Embodiment 1 in the continuous monitoring of flue gas, in this application example, the light source adopts a xenon lamp, and the emitted light has an absorption spectrum corresponding to nitric oxide and sulfur dioxide For the measurement light of the line, the lens group is used as the converging part, the grating is used as the spectroscopic part, and the detector adopts CMOS. The measuring pool is in a "concave" shape, and glass windows are arranged on both sides of the middle concave part to isolate the flue gas to be measured from the inner parts of the cavity, and the measurement optical path is between the windows. The light source and the converging lens are located on both sides of the window, so that the light emitted by the light source passes through the window and the smoke to be measured is converged at the slit by the converging lens.

[0080] In or...

Embodiment 3

[0086] According to the application example of the fluid analysis equipment and its debugging method described in Embodiment 1 in water quality analysis, in this application example, the light source is a xenon lamp, the lens group is used as a converging component, the grating is used as a spectroscopic component, and the detector is a CCD. The measuring pool is in a "concave" shape, and glass windows are arranged on both sides of the middle concave part to isolate the flue gas to be measured from the inner parts of the cavity, and the measurement optical path is between the windows. The light source and the converging lens are located on both sides of the window, so that the light emitted by the light source passes through the window and the water sample to be tested is converged at the slit by the converging lens.

[0087] In order to further adjust the measurement accuracy and range of the analysis equipment, the lens group and the slit are arranged in the first cavity thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com