Preparation method of graphene modified glassy carbon electrode and application thereof

A glassy carbon electrode and graphene technology, applied in the field of electrochemistry, can solve the problems of strong lattice, defects, and high toxicity of graphene products, achieve high sensitivity and accuracy, shorten reaction time, and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of graphene-modified glassy carbon electrode: (1) Add graphene oxide powder into distilled water for 90 minutes of ultrasonication to obtain a graphene oxide dispersion with a mass fraction of 0.5%;

[0035] (2) Clean the glassy carbon electrode, drop 10 μL of graphene oxide dispersion on the surface of the glassy carbon electrode, and let it dry;

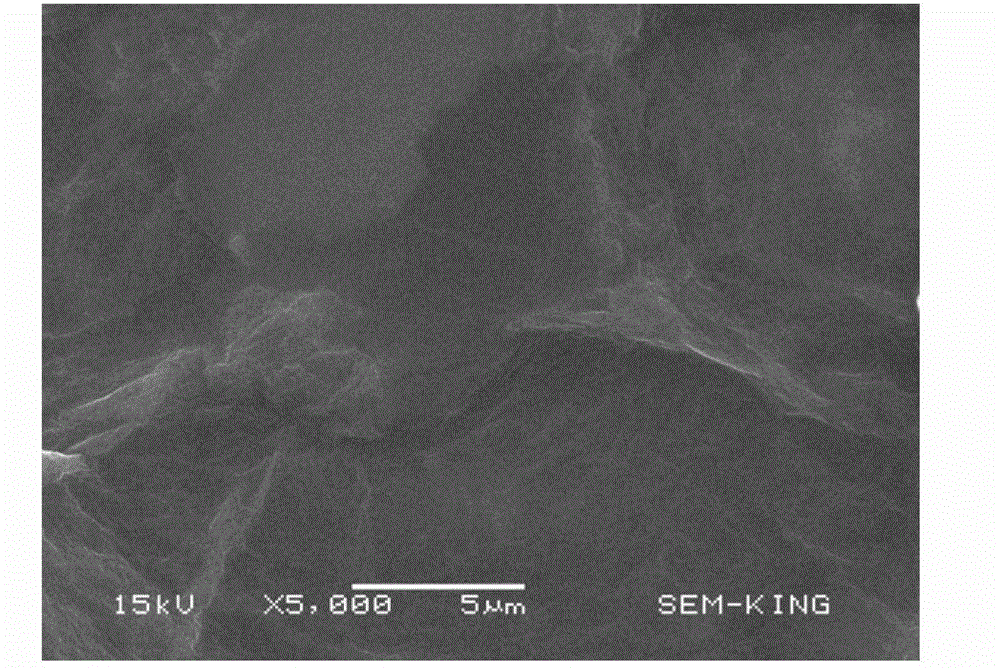

[0036] (3) Using graphene oxide modified glassy carbon electrode as working electrode, in 0.3mol / L NaH 2 PO 4 Electrochemical reduction at constant potential in the buffer solution. Nitrogen gas was passed for 10 minutes before the reduction, potential: -1.0V, time: 90 minutes, and the graphene-modified glassy carbon electrode was obtained after the reduction was completed. The SEM image of the prepared electrochemically reduced graphene-modified glassy carbon electrode is shown in figure 1 As shown, it can be seen from the figure that graphene is successfully supported on the glassy carbon electrode, that is, ...

Embodiment 2

[0047]Preparation of graphene-modified glassy carbon electrode: (1) Add graphene oxide powder into distilled water for 90 minutes of ultrasonication to obtain a graphene oxide dispersion with a mass fraction of 0.5%;

[0048] (2) Clean the glassy carbon electrode, drop 10 μL of graphene oxide dispersion on the surface of the glassy carbon electrode, and let it dry;

[0049] (3) Using graphene oxide modified glassy carbon electrode as the working electrode, in 0.1mol / L NaH 2 PO 4 Electrochemical reduction at constant potential in the buffer solution. Nitrogen gas was passed for 10 minutes before the reduction, potential: -0.9V, time: 120min, and the graphene-modified glassy carbon electrode was obtained after the reduction was completed.

[0050] The established analytical method was used for the determination of monascus red pigment in beverage samples. Preparation of sample solution: take 2.5mL sample, add deionized water to make up to 25mL solution.

[0051] (1) Add Na to...

Embodiment 3

[0057] Preparation of graphene-modified glassy carbon electrode: (1) Add graphene oxide powder into distilled water for 90 minutes of ultrasonication to obtain a graphene oxide dispersion with a mass fraction of 0.5%;

[0058] (2) Clean the glassy carbon electrode, drop 10 μL of graphene oxide dispersion on the surface of the glassy carbon electrode, and let it dry;

[0059] (3) Using graphene oxide modified glassy carbon electrode as the working electrode, in 0.1mol / L NaH 2 PO 4 Electrochemical reduction at constant potential in the buffer solution. Nitrogen gas was passed for 10 minutes before the reduction, potential: -1.1V, time: 80 minutes, and the graphene-modified glassy carbon electrode was obtained after the reduction was completed.

[0060] The established analytical method was used for the determination of erythrosin in beverage samples. Preparation of sample solution: take 2.5mL sample, add deionized water to make up to 25mL solution.

[0061] (1) Add Na to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com