High-concentration preservative bactericide

A technology of anti-corrosion bactericide and bactericide, applied in the direction of biocide, bactericide/microdynamic water/sewage treatment, disinfectant, etc., can solve the problems of reducing bactericidal activity, poor application effect of bactericide, and reducing rock permeability, etc. Achieve good application effect and low water treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

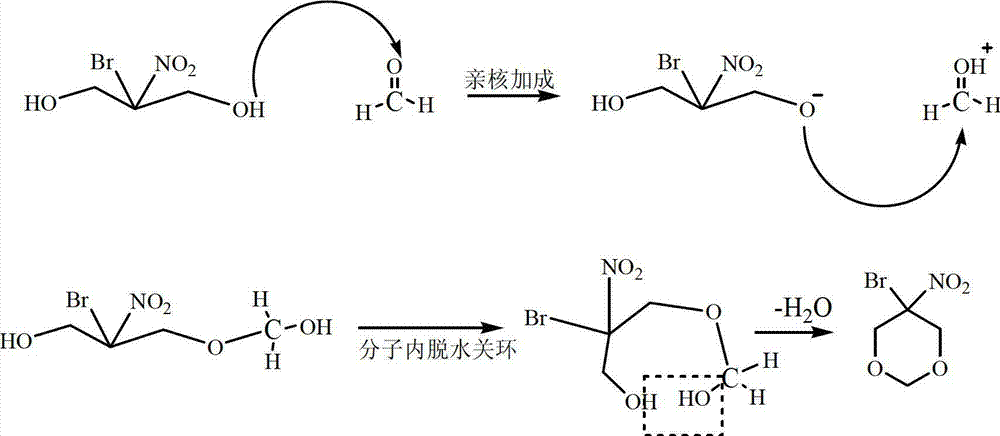

[0020] First, add 1.5mol (45g) formaldehyde and 1mol (155g) 2-bromo-2-nitropropanediol to a 250ml four-neck flask equipped with a condensing reflux tube device, heat and reflux at 60°C, react for 3 hours to the end of the reaction, and cool to room temperature, filter to remove excess formaldehyde, and obtain the intermediate product hydroxymethyl ether compound; then, in a four-necked flask equipped with a condenser and a water separator device, add excess toluene and the intermediate product hydroxymethyl ether compound, and heat to Reflux at 100°C, use a water separator to separate water, cool down and filter when no water comes out of the system, and obtain the dehydration ring-closing product 1,3-dioxane six-membered ring compound.

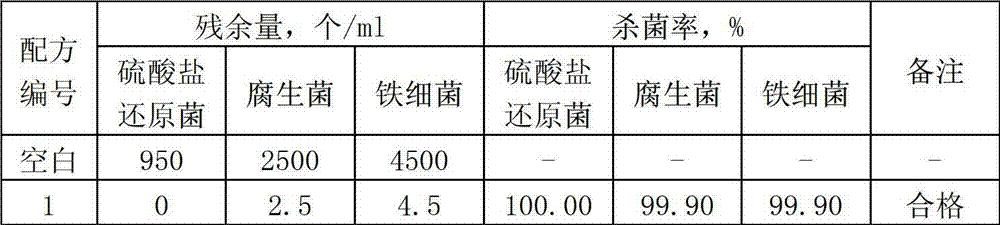

[0021] Compound the synthetic fungicide main agent 1,3-dioxane six-membered ring compound with dibromonitrilopropionamide: first put 40g of dibromonitrilopropionamide into the beaker, start stirring and add 60g of fungicide The main ingredien...

Embodiment 2

[0023] First, add 2 mol of formaldehyde and 1 mol of 2-bromo-2-nitropropanediol into a 250ml four-necked flask equipped with a condensing reflux tube device, heat and reflux at 60°C, react for 3 hours to the end of the reaction, cool to room temperature, and filter to remove excess formaldehyde to obtain the intermediate product hydroxymethyl ether compound; then, in a four-necked flask equipped with a condenser and a water separator device, add excess toluene and the intermediate product hydroxymethyl ether compound, heat to 90 ° C and reflux, and use a water separator to Separate the water, and when no water comes out in the system, cool and filter to obtain the dehydration ring-closing product 1,3-dioxane six-membered ring compound.

[0024] Compound the synthetic fungicide main agent 1,3-dioxane six-membered ring compound with dibromonitrilopropionamide: first put 50g of dibromonitrilopropionamide into the flask, start stirring and add 50g of fungicide The main ingredient,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com