Composite acidifier for reducing post-weaning diarrhea rate

A technology of weaning piglets diarrhea and compound acidifier, which is applied in the application, animal feed, animal feed and other directions, can solve the problems of buffering of feed materials, inability to complete intestinal adaptation as soon as possible, and without protection, etc., to achieve enhanced production performance and save feeding Cost, the effect of reducing the material-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of embodiment 1 compound acidulant

[0021] (1) Dilute 550g of sodium silicate to an aqueous solution of sodium silicate with a silica concentration of 12% (W / V);

[0022] (2) Mix half of the sodium silicate aqueous solution prepared in step (1) with 30% (W / V) hydrochloric acid solution at 30°C under constant stirring to obtain acidic silica sol;

[0023] (3) Heat the other half of the sodium silicate aqueous solution prepared in step (1) to 65°C, add 30% (W / V) hydrochloric acid solution, add the acidic silica sol obtained in step (2) while stirring, and add 20 g of ethyl acetate Ester, heat preservation and aging for 0.5h, spray drying at 450°C to obtain carrier silica gel;

[0024] (4) Mix the carrier silica gel obtained in step (3) with 315g of citric acid, 315g of formic acid, 220g of lactic acid and 158g of butyric acid, stir, filter after standing, and dry the filter cake to obtain a compound acidulant.

Embodiment 2

[0025] Embodiment 2 The preparation of compound acidulant

[0026] (1) Dilute 550g of sodium silicate to an aqueous solution of sodium silicate with a silicon dioxide concentration of 15% (W / V);

[0027] (2) Mix half of the sodium silicate aqueous solution prepared in step (1) with 25% (W / V) hydrochloric acid solution at 30°C under constant stirring to obtain acidic silica sol;

[0028] (3) Heat the other half of the sodium silicate aqueous solution prepared in step (1) to 60°C, add 25% (W / V) hydrochloric acid solution, add the acidic silica sol obtained in step (2) while stirring, and add 25g ethyl acetate Ester, heat preservation and aging for 0.5h, spray drying at 450°C to obtain carrier silica gel;

[0029] (4) Mix the carrier silica gel obtained in step (3) with 315g of citric acid, 315g of formic acid, 160g of lactic acid and 160g of butyric acid, stir, filter after standing, and dry the filter cake to obtain a compound acidulant.

Embodiment 3

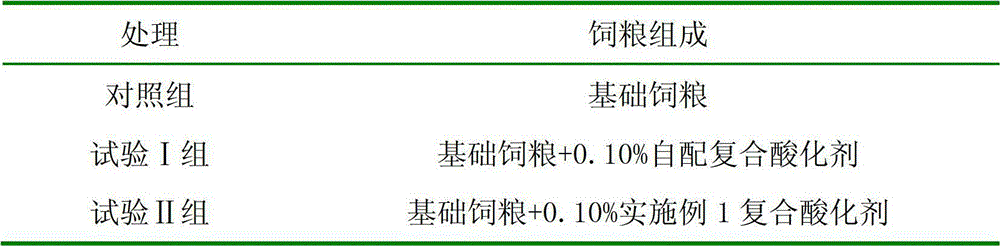

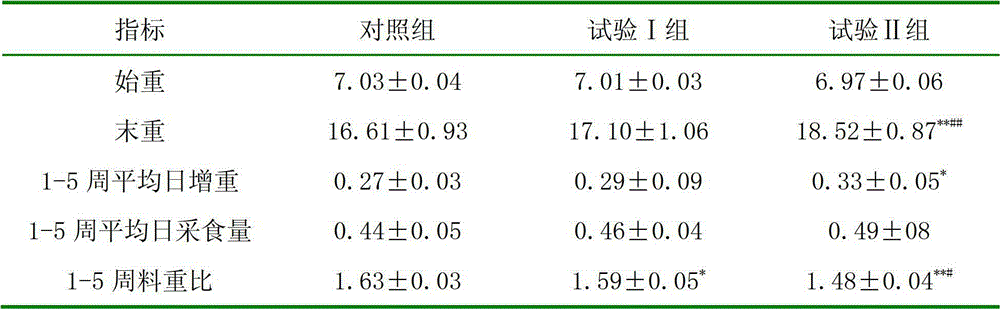

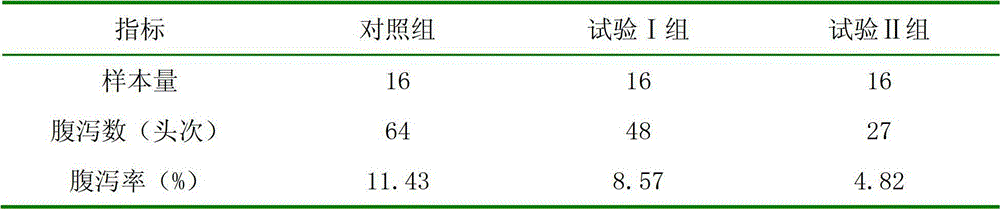

[0030] Example 3 Effect of compound acidifier on performance and diarrhea rate of weaned piglets

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com