Drug-loaded mixed micelle

A technology of mixing micelles and loading drugs, which can be applied in drug combinations, pharmaceutical formulations, antineoplastic drugs, etc., can solve the problems of immature paclitaxel nanomicelle technology and the lack of ideal long-term stable nanomicelles. Affinity and endocytosis, easy quality control, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

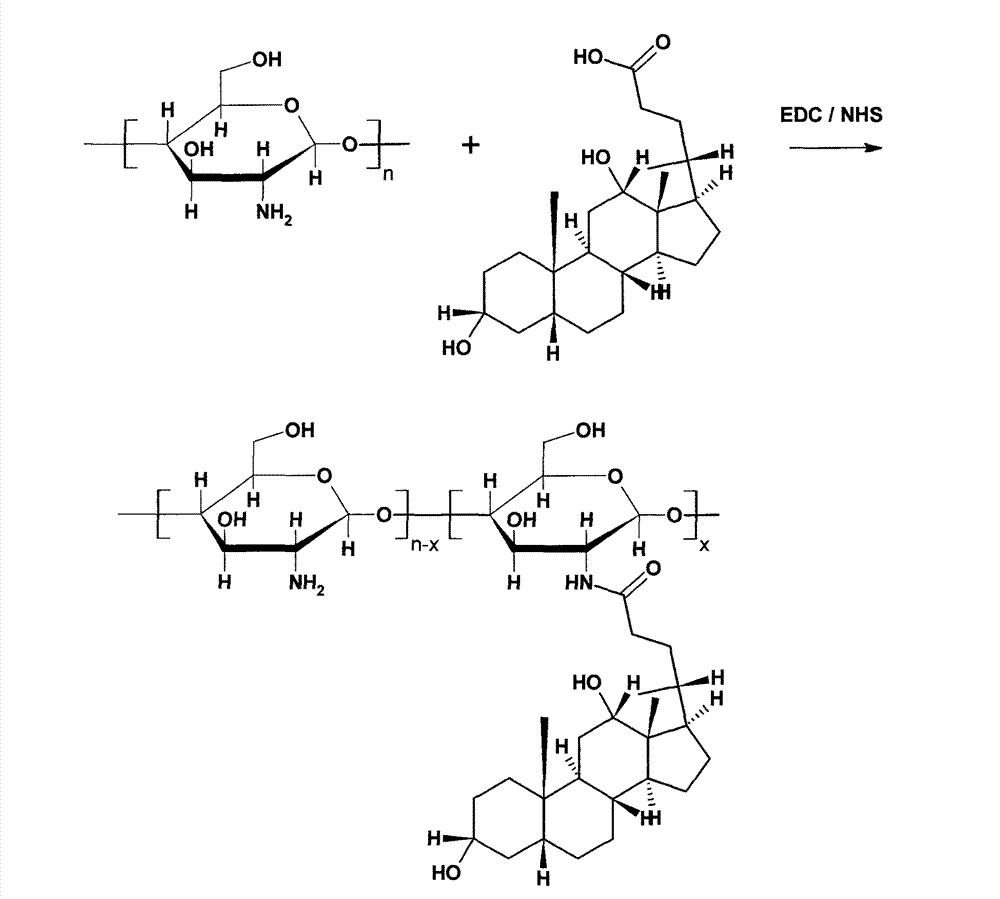

[0029] Embodiment 1: the synthesis of chitosan-cholic acid copolymer

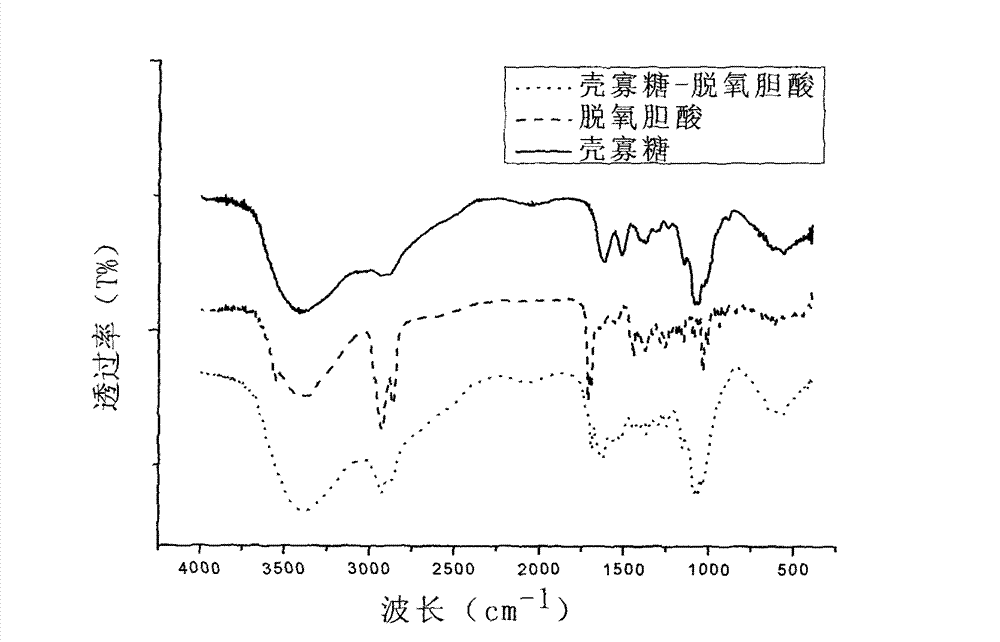

[0030] As indicated by the synthesis figure 1 As shown, take chitosan (average molecular weight is 5000) 160mg (0.032mol), carbodiimide (EDC) 194.7mg, N-hydroxysuccinimide 116.3mg and deoxycholic acid 32mg (0.082mol) add 100mL In the reactor, add 40mL methanol and water mixed solution with a volume ratio of 1:1 in the reactor, stir for 24 hours, dialyze and freeze-dry the reaction solution to obtain the chitosan-cholic acid copolymer. The Fourier transform infrared spectrum (FTIR) of chitosan, deoxycholic acid and their graft copolymers are as follows: figure 2 shown. The results showed that cholic acid was successfully attached to the end group of chitosan.

Embodiment 2

[0031] Embodiment 2: the synthesis of chitosan-cholic acid copolymer

[0032] As indicated by the synthesis figure 1 As shown, take chitosan (average molecular weight is 10000) 300mg (0.03mol), carbodiimide (EDC) 180mg, N-hydroxysuccinimide 105mg and deoxycholic acid 11.8mg (0.03mol) add 100mL reaction In the reactor, add 40mL of methanol and water into the reactor with a volume ratio of 1:1 mixed solution, stir for 24 hours, dialyze and freeze-dry the reaction solution to obtain the chitosan-cholic acid copolymer.

Embodiment 3

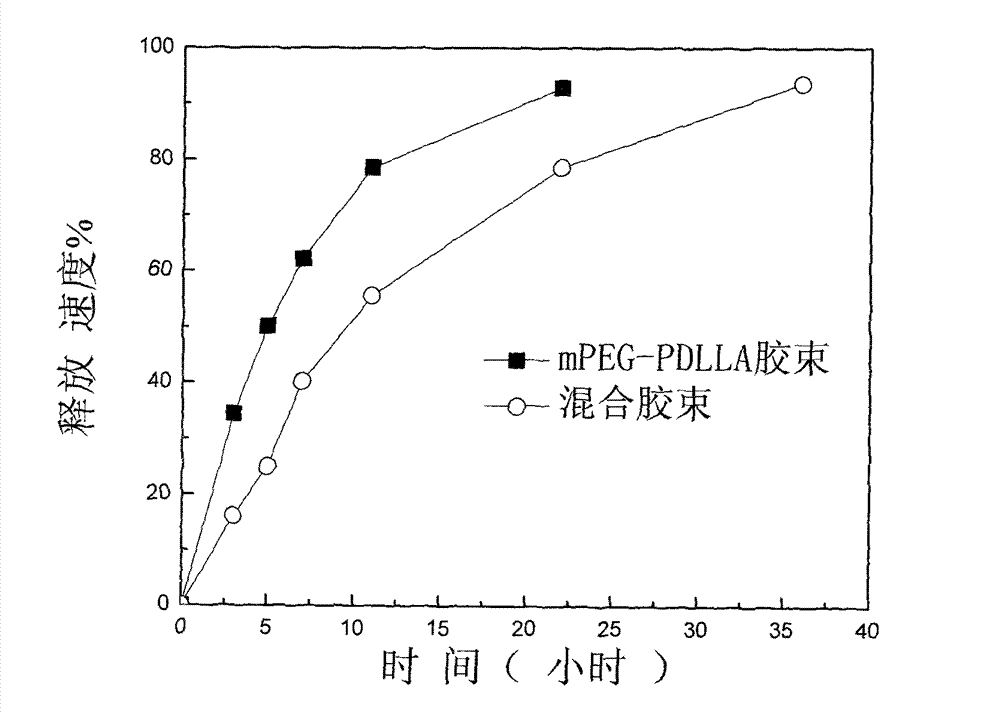

[0033] Example 3: Preparation of single-component mPEG-PDLLA nanomicelles containing paclitaxel

[0034] Dissolve 100mg of mPEG-PDLLA (molecular weight: 4000) and 20mg of paclitaxel in 4mL of methanol, and rotate under reduced pressure at 60°C to form a film. After the film is formed, continue to rotate under vacuum for 1 hour, and then transfer to a vacuum drying oven to continue drying. After 12 hours of vacuum drying, add water and hydrate at 60° C. for 20 minutes in a rotary evaporator under normal pressure to obtain nanomicelles. The encapsulation efficiency of the micelles is 90.4%, the particle size is 32nm, and the surface charge is -8.9mV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com