Medical active carbon fiber dressing and preparation method thereof

The technology of activated carbon fiber and activated carbon fiber cloth is applied in the field of activated carbon fiber medical dressing and its preparation, and achieves the effects of good adsorption and comfort, reducing pain and preventing infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

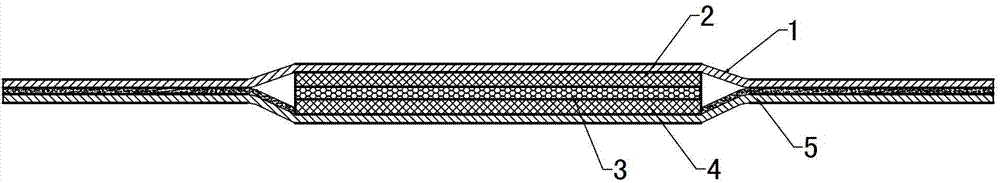

[0023] Example 1: Put the activated carbon fiber into the sample bag and seal it with 60 Co-γ rays are pre-irradiated, and the irradiation dose is 48kGy to obtain pre-irradiated activated carbon fibers. Pre-irradiated activated carbon fibers were mixed with 25% acrylic acid monomer solution in water system, 4×10 -4 mol / L mohr salt, reacted at 70°C for 3h under a nitrogen atmosphere, washed with water, and dried at 50°C to prepare activated carbon fiber cloth and activated carbon fiber felt. Calcium alginate fiber is used as raw material, the alginate fiber membrane is prepared by needle punching process, the multi-layer composite process is adopted, the activated carbon fiber cloth 2 is used as the inner layer, the activated carbon fiber felt 4 is used as the adsorption enhancement layer, and the alginate fiber membrane 3 is used as the binding layer The activated carbon fiber composite dressing is made, and the outer layer is made of a non-woven fabric 5 coated with medica...

Embodiment 2

[0024] Example 2: Put the activated carbon fiber into the sample bag and seal it with 60 Co-γ rays are pre-irradiated, and the irradiation dose is 48kGy to obtain pre-irradiated activated carbon fibers. The pre-irradiated activated carbon fiber was mixed with methanol system and 15% acrylic acid monomer solution, 2×10 -4 mol / L Mohr salt, reacted at 50°C for 5h under nitrogen atmosphere, washed with water, and dried at 60°C to prepare activated carbon fiber cloth and activated carbon fiber felt. Calcium alginate fiber is used as raw material, the alginate fiber membrane is prepared by needle punching process, the multi-layer composite process is adopted, the activated carbon fiber cloth 2 is used as the inner layer, the activated carbon fiber felt 4 is used as the adsorption enhancement layer, and the alginate fiber membrane 3 is used as the binding layer The activated carbon fiber composite dressing is made, and the outer layer is made of a non-woven fabric 5 coated with me...

Embodiment 3

[0025] Example 3: Put the activated carbon fiber into the sample bag and seal it with 60 Co-γ rays are pre-irradiated, and the irradiation dose is 48kGy to obtain pre-irradiated activated carbon fibers. Pre-irradiated activated carbon fibers were mixed with 35% acrylate monomer solution in water system, 8×10 -4 mol / L mohr salt, reacted at 90°C for 2h under a nitrogen atmosphere, washed with water, and dried at 45°C to prepare activated carbon fiber cloth and activated carbon fiber felt. Calcium alginate fiber is used as raw material, the alginate fiber membrane is prepared by needle punching process, the multi-layer composite process is adopted, the activated carbon fiber cloth 2 is used as the inner layer, the activated carbon fiber felt 4 is used as the adsorption enhancement layer, and the alginate fiber membrane 3 is used as the binding layer The activated carbon fiber composite dressing is made, and the outer layer is made of a non-woven fabric 5 coated with medical st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com