Processing method for improving toughness of hard film

A processing method and thin film technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of small effect and limited wide use, so as to improve brittle fracture resistance, solve brittle failure, and improve toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The treatment method for improving the toughness of the hard film in this embodiment is: using physical vapor deposition method (specifically arc ion plating assisted enhanced magnetron sputtering) to prepare SiCN with a thickness of 10 μm and a Vickers hardness of 42 GPa on the surface of a single crystal Si substrate. Hard film; then use the MEVVA source (i.e. metal vapor vacuum arc ion source) ion implanter to implant ions into the SiCN hard film, using a graphite target with a mass purity of 99.99%, the implanted ion energy is 10kev, and the implanted ion The dose is 5 x 10 15 ions / cm 2 , the implanted ions are carbon ions.

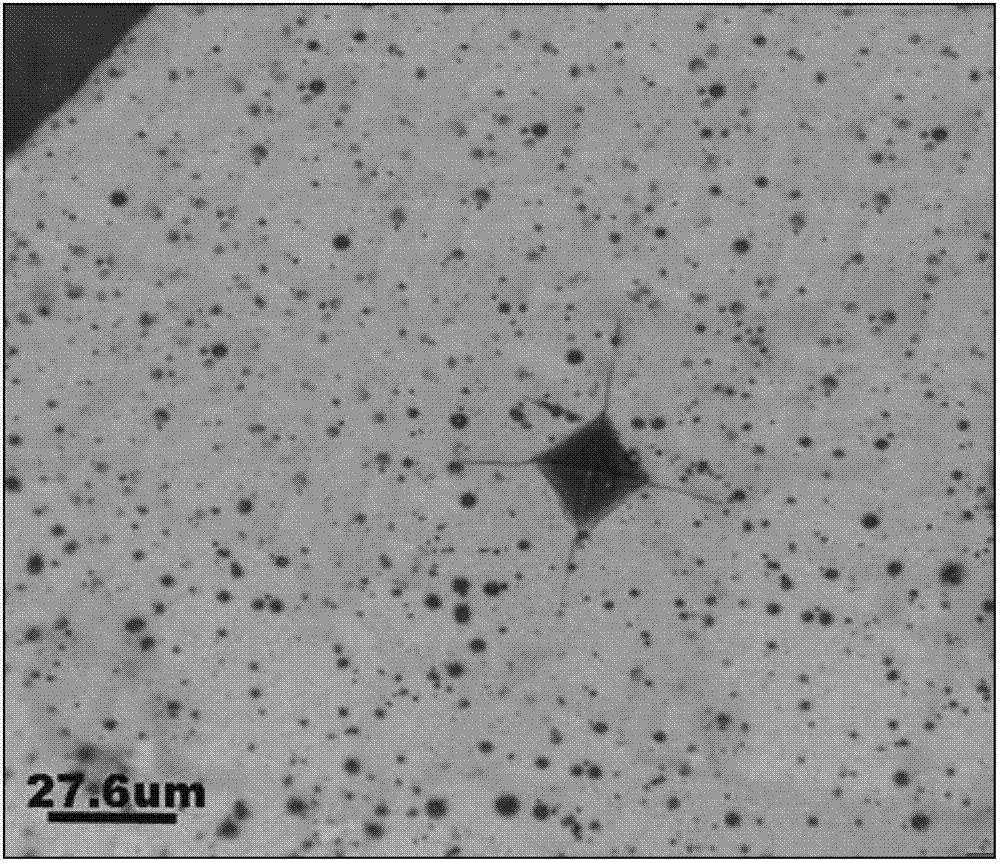

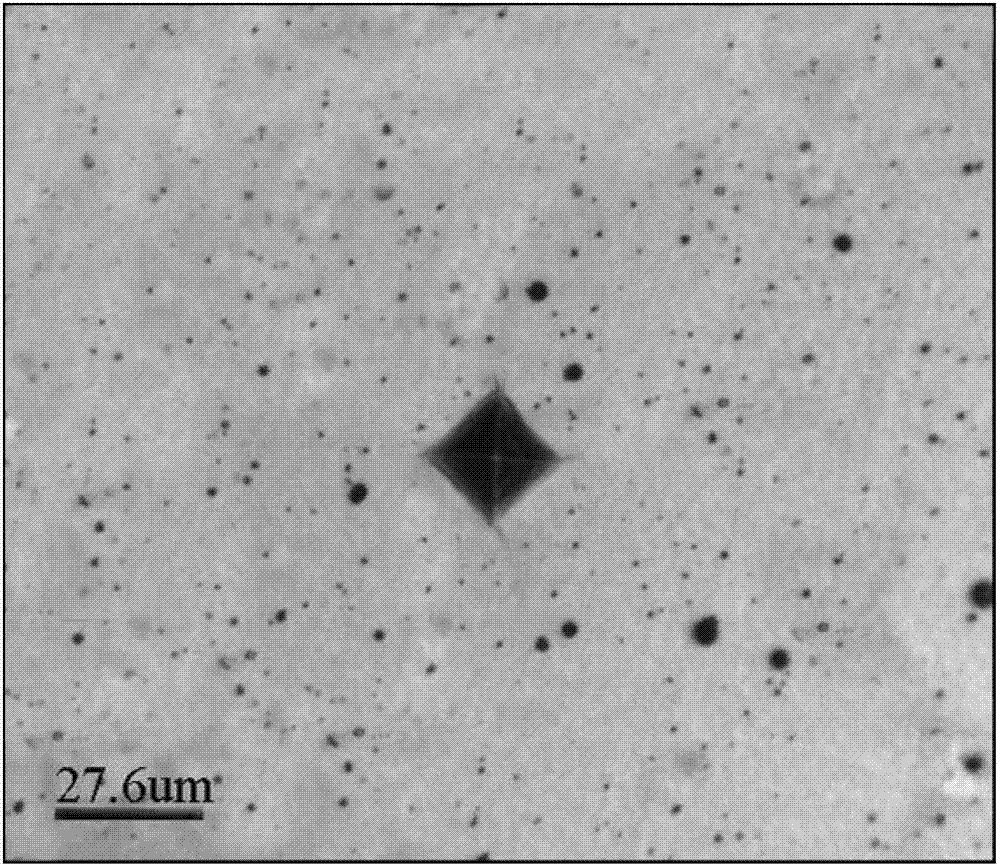

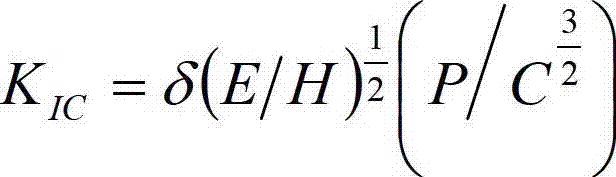

[0028] The SiCN hard film before ion implantation in this embodiment was subjected to a Vickers hardness test under the condition of a load of 5N, and the obtained indentation fracture morphology was as follows figure 1 As shown, according to the formula, the toughness value of the SiCN hard film before implanting ions in this embodiment is 0...

Embodiment 2

[0030] The treatment method for improving the toughness of the hard film in this embodiment is: using physical vapor deposition (specifically magnetron sputtering) to prepare a TiAlSiN hard film with a thickness of 8 μm and a Vickers hardness of 36 GPa on the surface of the W18Cr14V high-speed steel substrate; and then Use the MEVVA source (metal vapor vacuum arc ion source) ion implanter to implant ions into the TiAlSiN hard film, use a pure aluminum target with a mass purity of 99.99%, the implanted ion energy is 70kev, and the implanted ion dose is 6×10 16 ions / cm 2 , the implanted ions are aluminum ions.

[0031] The toughness value of TiAlSiN hard film before ion implantation in this example is 0.64MPa·m 1 / 2 , the toughness value of TiAlSiN hard film after ion implantation in this example is 6.3MPa·m 1 / 2 , indicating that the toughness of the TiAlSiN hard film is significantly improved after ion implantation in this embodiment.

Embodiment 3

[0033] The treatment method for improving the toughness of the hard film in this embodiment is: using physical vapor deposition method (specifically arc ion plating) to prepare a TiCrAlN hard film with a thickness of 5 μm and a Vickers hardness of 28 GPa on the surface of the cemented carbide substrate; The MEVVA source (metal vapor vacuum arc ion source) ion implanter implants ions into the TiCrAlN hard film, using a pure chromium target with a mass purity of 99.99%, the implanted ion energy is 150kev, and the implanted ion dose is 3×10 13 ions / cm 2 , the implanted ions are chromium ions.

[0034] The toughness value of TiCrAlN hard film before ion implantation in this example is 0.71MPa·m 1 / 2 , the toughness value of TiCrAlN hard film after ion implantation in this example is 6.14MPa·m 1 / 2 , indicating that the toughness of the TiCrAlN hard film is significantly improved after ion implantation in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com