Desulfurization synergist having scale inhibition performance, and preparation method thereof

A technology of synergist and antiscalant, which is applied in the field of desulfurization synergist with antiscaling performance and its preparation, can solve the problems of easy scaling of the system and high energy consumption of the desulfurization system, and achieve good economic and environmental benefits , Reduce labor intensity, easy to wash and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

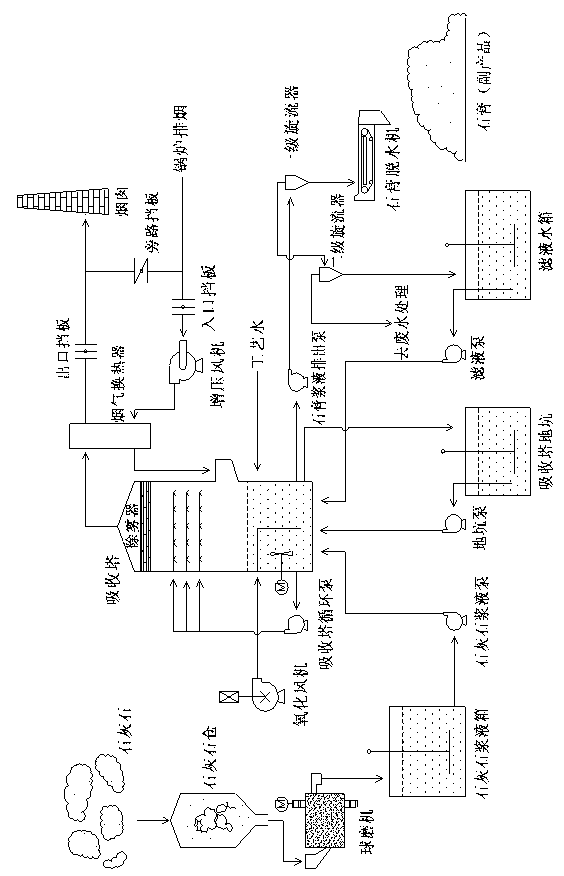

Method used

Image

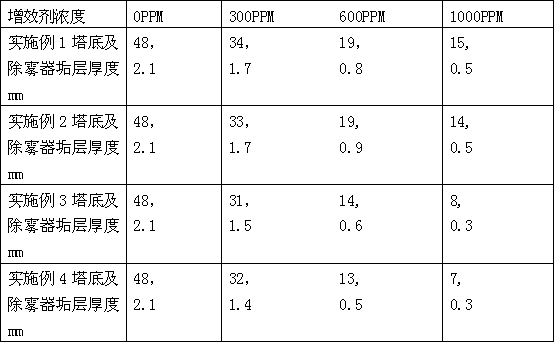

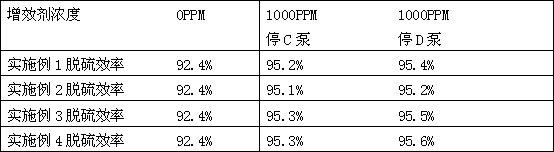

Examples

Embodiment 1

[0037] A desulfurization synergist with anti-scaling performance, which is compounded from the following raw materials,

[0038] The mass percentage of raw materials is:

[0039] Trisodium Citrate 50%,

[0040] Sodium acetate 22%,

[0041] Sodium lignosulfonate 5%,

[0042] Sodium Polyepoxysuccinate 8%,

[0043] Sodium Polyacrylate 7%,

[0044] Amino Trimethylene Phosphonic Acid (ATMP) 7%,

[0045] Fluorescent tracer 1%.

[0046] In the preparation method of the above-mentioned desulfurization synergist with scale-inhibiting properties, the above-mentioned raw materials are mixed and stirred for 1-2 hours to obtain the desulfurization synergist with scale-inhibiting properties.

Embodiment 2

[0048] A desulfurization synergist with anti-scaling performance, which is compounded from the following raw materials,

[0049] The mass percentage of raw materials is:

[0050] Sodium 2-Hydroxypropionate 35%,

[0051] Sodium formate 45%,

[0052] Sodium lignosulfonate 3%,

[0053] Sodium Polyepoxysuccinate 8%,

[0054] Sodium Polyacrylate 7%,

[0055] Fluorescent tracer 2%.

[0056] The preparation method of the above-mentioned desulfurization synergist with scale-inhibiting performance is to mix and stir the above-mentioned raw materials for 1-2 hours (in a powder mixing agitator) to obtain the desulfurization synergist with scale-inhibiting performance.

Embodiment 3

[0058] A desulfurization synergist with anti-scaling performance, which is compounded from the following raw materials,

[0059] The mass percentage of raw materials is:

[0060] Sodium glutarate 25%,

[0061] Sodium Adipate 35%,

[0062] Disodium Hydroxysuccinate 28%,

[0063] Carboxylate-sulfonate-nonionic terpolymer 3100 6%,

[0064] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer AA / AMPS 4%,

[0065] Fluorescent tracer 2%.

[0066] The preparation method of the above-mentioned desulfurization synergist with scale-inhibiting performance is to mix and stir the above-mentioned raw materials for 1-2 hours (in a powder mixing agitator) to obtain the desulfurization synergist with scale-inhibiting performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com