Method for preparing casting-use water glass by using casting waste sand

A technology for casting waste sand and water glass, which is used in foundry molding equipment, machinery for cleaning/processing mold materials, molds, etc., to achieve the effect of saving silica sand resources, reducing mining, significant economic value and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

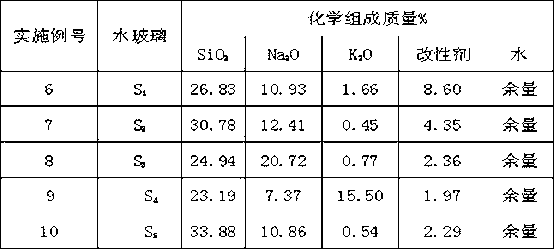

[0048] The chemical composition of waste sand using ester hardened sodium silicate sand is: SiO 2 : 82.1%, CH 3 COO Na: 11%, CH 3 COOK: 2.9%, others: 4.0%.

[0049] Soda ash is secondary soda ash for industrial use, Na 2 CO 3 The content is 98.5%.

[0050] Feeding mass ratio: waste sand 60%, soda ash 40.%, mix with a mixer, add horseshoe flame foam soda kiln with a feeder at a feed rate of 35 Kg per minute, heat with gas, and control the furnace temperature at 1380- At 1420°C, the furnace material melts and reacts to form sodium silicate and potassium silicate, which flows out of the discharge port into water for quenching, granulation, lifting, dehydration, and packaging to obtain solid water glass mixed with sodium silicate, silicon and potassium silicate. For: SiO 2 : 66.00%, Na 2 O: 29.70%, K 2 O: 1.10%, others: balance.

[0051] Denote it as M2.2.

Embodiment 2

[0053] The chemical composition of waste sand using ester hardened sodium silicate sand is: SiO 2 : 90%, CH 3 COO Na: 7.0%, CH 3 COOK: 1.8%, others: 1.2%.

[0054] Soda ash is the first grade soda ash for industrial use, Na 2 CO 3 Content 99%.

[0055] Ratio of feeding mass: waste sand 62.5%, soda ash 37.5%, mix with a mixer, use a feeder to add horseshoe flame foam soda kiln at a feeding speed of 35 Kg per minute, heat with natural gas, and control the furnace temperature at 1380- At 1420°C, the furnace material melts and reacts to form sodium silicate and potassium silicate, which flows out from the discharge port into water for quenching, granulation, lifting, dehydration, and packaging to obtain mixed solid water glass of sodium silicate and potassium silicate. Its chemical composition For: SiO 2 : 71.02%, Na 2 O: 27.36%, K 2 O: 0.68%, others: balance. Denote it as M2.6.

Embodiment 3

[0057] The chemical composition of waste sand using ester hardened sodium silicate sand is: SiO 2 : 95%, CH 3 COO Na: 3.5%, CH 3 COOK: 1.0%, others: 0.5%.

[0058] Soda ash is the first grade soda ash for industrial use, Na 2 CO 3 The content is 99%.

[0059] Feeding mass ratio: waste sand 66.2%, soda ash 33.8%, mix with a mixer, use a feeder to add horseshoe flame foam soda kiln at a feed rate of 35 Kg per minute, heat with gas, and control the furnace temperature at 1380-1420 ℃, the furnace material melts, reacts to form sodium silicate and potassium silicate, and flows into the water from the discharge port to quench, granulate, lift, dehydrate, and package to obtain mixed solid water glass of sodium silicate and potassium silicate. Its chemical composition is :SiO2 2 : 75.41%, Na 2 O: 23.81%, K 2 O: 0.38%, others: balance.

[0060] Recorded as M3.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com