Method for preparing pinacol by dehydrogenation of photocatalytic isopropanol dehydrogenation and hydrogenation coupling of acetone

A technology of isopropanol and photocatalysis, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., to achieve the effects of single catalyst component, improved photocatalytic efficiency and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

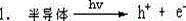

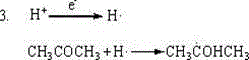

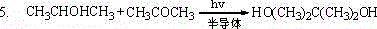

Method used

Image

Examples

Embodiment 1

[0028] 1 g TiO 2 The photocatalyst was added to the 55.5 ml acetone-19.1 ml isopropanol-125.4 ml water reaction solution, argon gas was introduced under magnetic stirring, and after the air in the system was removed, a 300W high-pressure mercury lamp was turned on to carry out photocatalytic dehydrogenation of isopropanol and Acetone hydrogenation coupling reaction to prepare pinacol, reaction temperature 55 ℃, reaction time 36 h. After the reaction, the reaction solution was separated by static precipitation, and the solution was distilled to obtain the product pinacol. Chromatographic analysis showed that the conversion rate of acetone was 78.1%, the conversion rate of isopropanol was 63.8%, and the selectivity of pinacol was 91.2%.

Embodiment 2

[0030] After calcination at 600℃ for 8 h, 1 g TiO 2 The photocatalyst was added to the reaction solution of 18.5 ml acetone-19.1 ml isopropanol-120 ml water-42.4 ml cyclohexane, argon gas was introduced under magnetic stirring, and after the air in the system was removed, a 300 W high-pressure mercury lamp was turned on for photocatalyst Catalyze the coupling reaction of isopropanol dehydrogenation and acetone hydrogenation to prepare pinacol, the reaction temperature is 50℃, and the reaction time is 24 h. After the reaction, the reaction solution was separated by static precipitation. Chromatographic analysis showed that the conversion rate of acetone was 76.1%, the conversion rate of isopropanol was 52.8%, and the selectivity of pinacol was 83.4%.

Embodiment 3

[0032] Add 2.5 g of sodium tantalate photocatalyst prepared by hydrothermal method to 50 ml of acetone-50 ml of isopropanol-80 ml of water-20 ml of cyclohexane water reaction solution, and pass in argon gas under magnetic stirring to remove the After airing, a 500 W high-pressure mercury lamp was turned on to carry out the coupling reaction of photocatalytic isopropanol dehydrogenation and acetone hydrogenation to prepare pinacol. The reaction temperature was 45 °C and the reaction time was 180 h. After the reaction, the reaction solution was separated by static precipitation. Chromatographic analysis showed that the conversion rate of acetone was 93.5%, the conversion rate of isopropanol was 90.7%, and the selectivity of pinacol was 90.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com