Preparation method of chiral alpha-difluoromethyl phenyl ethylamine

A technology of difluoromethylphenylethylamine and difluoromethyl is applied in the field of chiral α-difluoromethylphenylethylamine compound and preparation, and can solve the problem of high cost, unobtainable raw materials, incapable of industrialized production, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Preparation of (R)-α-difluoromethylphenylethylamine

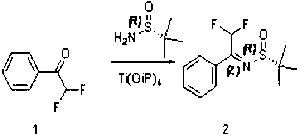

[0015] 1: Preparation of (2,2-difluoromethyl-1-phenyl-ethyl)-(R)-tert-butylsulfinimide

[0016] Reaction formula:

[0017]

[0018] Steps:

[0019] Take a 1000ml round bottom flask and put it into a magnetic stirrer and a reflux condenser, add 2,2-difluoro-1-phenylethanone (74 g, 470 mmol), (R)-tert-butylene Sulfonamide (68.9 g, 570 mmol), tetraethyl titanate (159 g, 700 mmol) and 400 ml tetrahydrofuran. The reaction mixture was refluxed for 3 hours under nitrogen protection. After cooling to room temperature, the reaction solution was poured into 1L of water, extracted with ethyl acetate, the organic phase was concentrated under reduced pressure, and purified by silica gel chromatography to obtain (2,2-difluoromethyl-1-phenyl-ethyl)- (R)-tert-Butylsulfinimide (89 g, 73%).

[0020] 1 : (CDCl 3 , 400 MHz) δ: 8.09 (br, 2H, Ar-H); 7.55 (m, 3H, Ar-H); 1.34 (s, 9H, t-Bu).

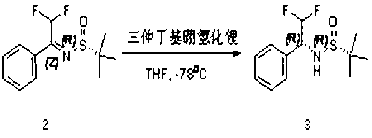

[0021] 2: Preparatio...

Embodiment 2

[0033] Embodiment 2: Preparation of (S)-α-difluoromethylphenylethylamine

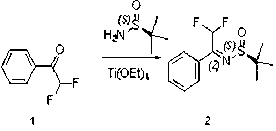

[0034] 1: Preparation of (2,2-difluoromethyl-1-phenyl-ethyl)-(S)-tert-butylsulfinimide

[0035] Reaction formula:

[0036]

[0037] Steps:

[0038] Take a 1000ml round bottom flask and put it into a magnetic stirring bar and install a reflux condenser, add 2,2-difluoro-1-phenylethanone (66g, 420 mmol) to it, (S)-tert-butylene Sulfonamide (60 g, 500 mmol), tetraethyl titanate (134 g, 625 mmol) and 400 ml tetrahydrofuran. The reaction mixture was refluxed for 3 hours under nitrogen protection. After cooling to room temperature, the reaction solution was poured into 1L of water, extracted with ethyl acetate, the organic phase was concentrated under reduced pressure, and purified by silica gel chromatography to obtain (2,2-difluoromethyl-1-phenyl-ethyl)- (R)-tert-Butylsulfinimide (80 g, 74%).

[0039] 1 : (CDCl 3 , 400 MHz) δ: 8.09 (br, 2H, Ar-H); 7.55 (m, 3H, Ar-H); 1.34 (s, 9H, t-Bu) 。

[0...

Embodiment 3

[0052] Embodiment 3: Preparation of (R)-α-difluoromethylphenylethylamine

[0053] 1: Preparation of (2,2-difluoromethyl-1-phenyl-ethyl)-(R)-tert-butylsulfinimide

[0054] Reaction formula:

[0055]

[0056] Steps:

[0057] Take a 100ml round-bottomed flask and put it into a magnetic stirrer and a reflux condenser, add 2,2-difluoro-1-phenylethanone (5 g, 32 mmol), (R)-tert-butylene Sulfonamide (5 g, 41 mmol ), tetraisopropyl titanate (14.2 g, 50 mmol) and 50 ml tetrahydrofuran. The reaction mixture was refluxed for 3 hours under nitrogen protection. After cooling to room temperature, the reaction solution was poured into 200ml of water, extracted with ethyl acetate, the organic phase was concentrated under reduced pressure, and purified by silica gel chromatography to obtain (2,2-difluoromethyl-1-phenyl-ethyl)- (R)-tert-Butylsulfinimide (5.3 g, 64%).

[0058] 1 : (CDCl 3 , 400 MHz) δ: 8.09 (br, 2H, Ar-H); 7.55 (m, 3H, Ar-H); 1.34 (s, 9H, t-Bu).

[0059] 2: Prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com