Diazoacetate-ethoxycarbonyl carbene copolymer and preparation method thereof

A technology of diazoacetate and ethoxycarbonyl card, applied in the field of polymer chemistry, can solve problems such as destruction, waste of resources and environment, and achieve the effects of non-toxic reaction, energy saving and convenient synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

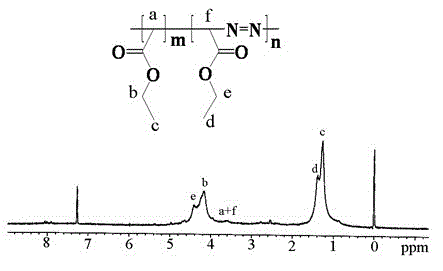

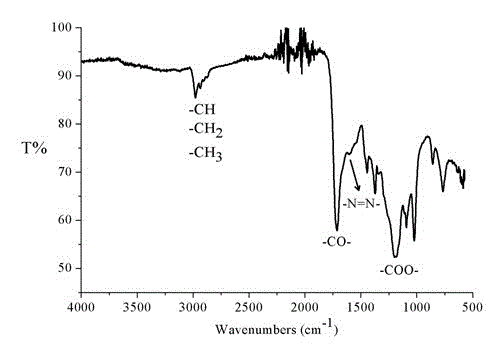

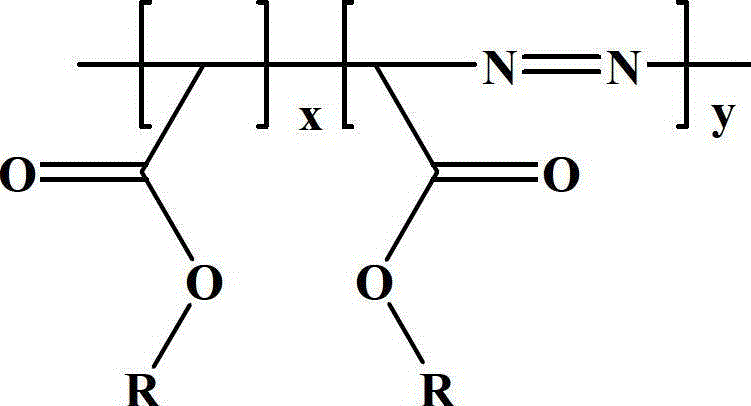

Method used

Image

Examples

Embodiment 1

[0020] Under the protection of argon, place 0.01mol ethyl diazoacetate in the reaction flask, irradiate with 200W microwave for 30 minutes, add tetrahydrofuran to dissolve after cooling, then drop a large amount of petroleum ether for re-precipitation, and centrifuge to obtain the precipitate , vacuum dried. The yield was 61.9%, and the obtained polymer had a carbon content of 60.66%, a hydrogen content of 4.72%, a nitrogen content of 7.95%, and a molecular weight of 6300 g / mol.

Embodiment 2

[0022] Under the protection of argon, place 0.01mol ethyl diazoacetate in the reaction flask, irradiate with 200W microwave for 60 minutes, add tetrahydrofuran to dissolve after cooling, then drop a large amount of petroleum ether for re-precipitation, and centrifuge to obtain the precipitate , vacuum dried. The yield was 63.8%, and the resulting polymer had a carbon content of 60.31%, a hydrogen content of 5.07%, a nitrogen content of 8.04%, and a molecular weight of 35400 g / mol.

Embodiment 3

[0024] Under the protection of argon, place 0.01mol ethyl diazoacetate in the reaction flask, irradiate with 200W microwave for 90 minutes, add tetrahydrofuran to dissolve after cooling, then drop a large amount of petroleum ether for re-precipitation, and centrifuge to obtain the precipitate , vacuum dried. The yield was 68.1%, and the resulting polymer had a carbon content of 59.08%, a hydrogen content of 5.08%, a nitrogen content of 8.18%, and a molecular weight of 22300 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com