Chloroprene rubber/butyl rubber sealing gasket and its preparation method

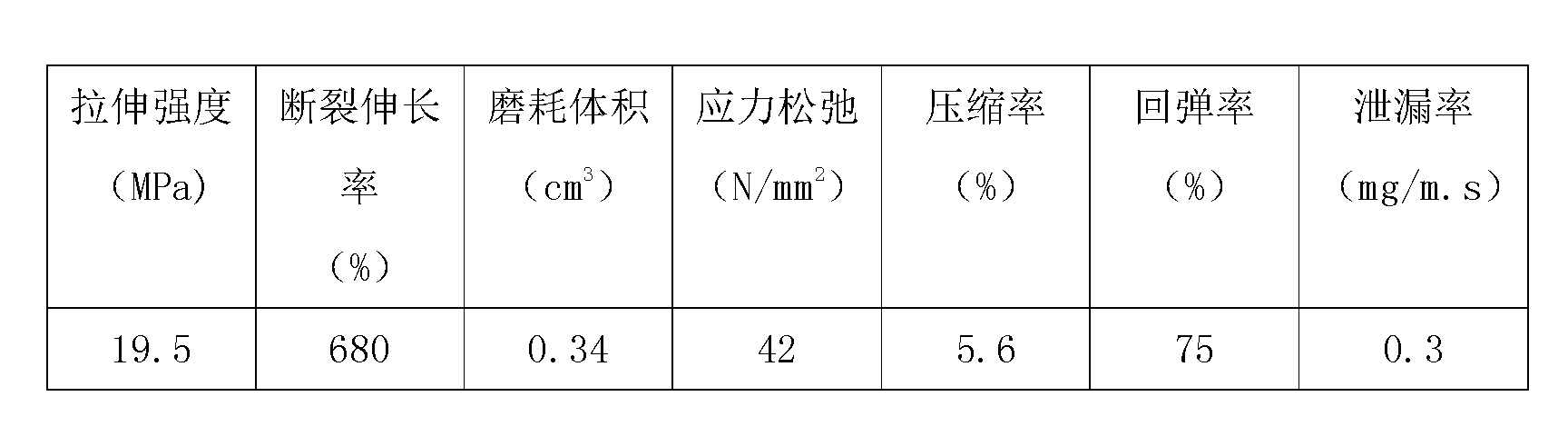

A technology of butyl rubber and neoprene rubber, applied in the field of gaskets, can solve the problems of unsatisfactory sealing effect, poor wear resistance, low strength, etc., and achieve the effects of excellent effect, good wear resistance and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] A neoprene / butyl rubber sealing gasket, the parts by weight of its raw materials are: 138 parts of neoprene CR121, 15 parts of butyl rubber CBK139, 12 parts of bromobutyl rubber 1066, 4 parts of propylene glycol sebacate 5 parts, 5 parts of n-butyl methacrylate, 2 parts of di-n-octyl tin bis-thioglycolate, 2 parts of zinc stearate, 3 parts of zinc oxide, 3 parts of magnesium oxide, 8 parts of light calcium carbonate, nano recrystallization 42 parts of stone powder, 22 parts of nano-bentonite, 1.5 parts of isopropyl dioleate (dioctyl phosphate acyloxy) titanate, 1.8 parts of antioxidant 1035, 3-aminopropyl trimethoxysilane 1.2 parts, accelerator TETD 1.2 parts, accelerator CBS 0.8 parts, antioxidant NBC 1.5 parts, antioxidant MB 1.5 parts, antioxidant 4010NA 2 parts, modified tree ash 2 parts.

[0016] Wherein, the modified tree ashes are prepared by the following method: first soak the tree ashes with 15% hydrogen peroxide for 3 hours, then wash with deionized water unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com