Universal nanoscale electrospining regionalization method

An electrospinning, regionalized technology, applied in biochemical equipment and methods, textiles and papermaking, filament/thread forming, etc., can solve problems such as low flux, inability to regionalize electrospinning, and single research conditions. Achieve the effect of controllable area, reduced screening cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

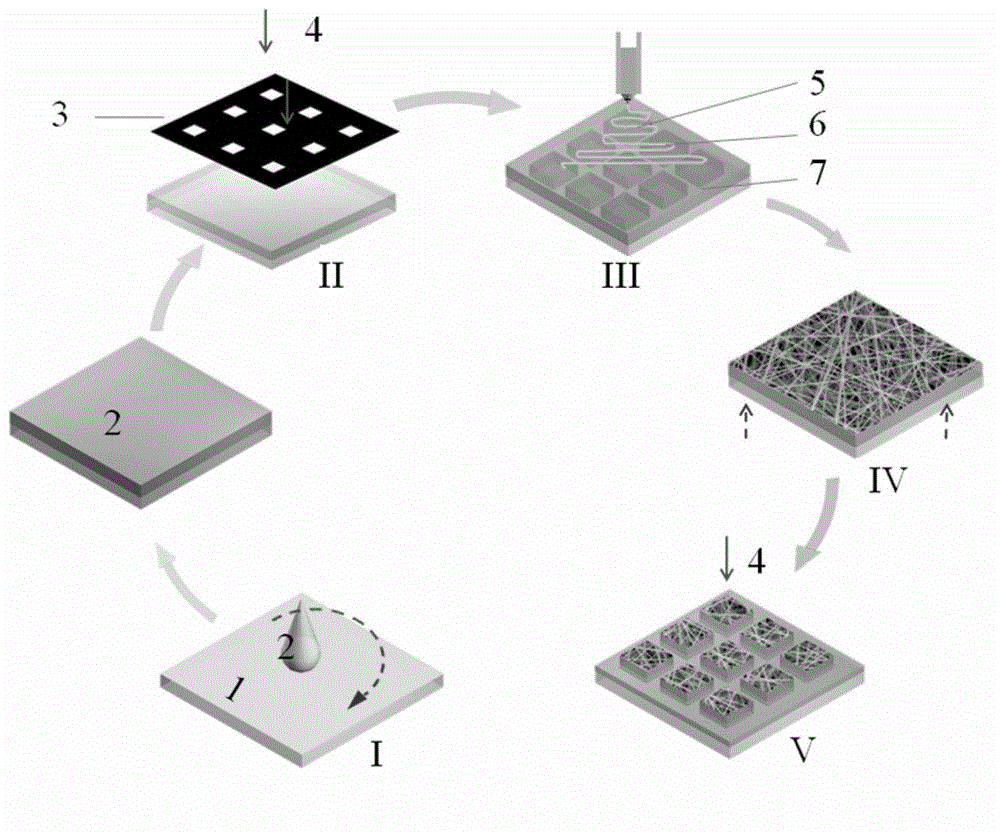

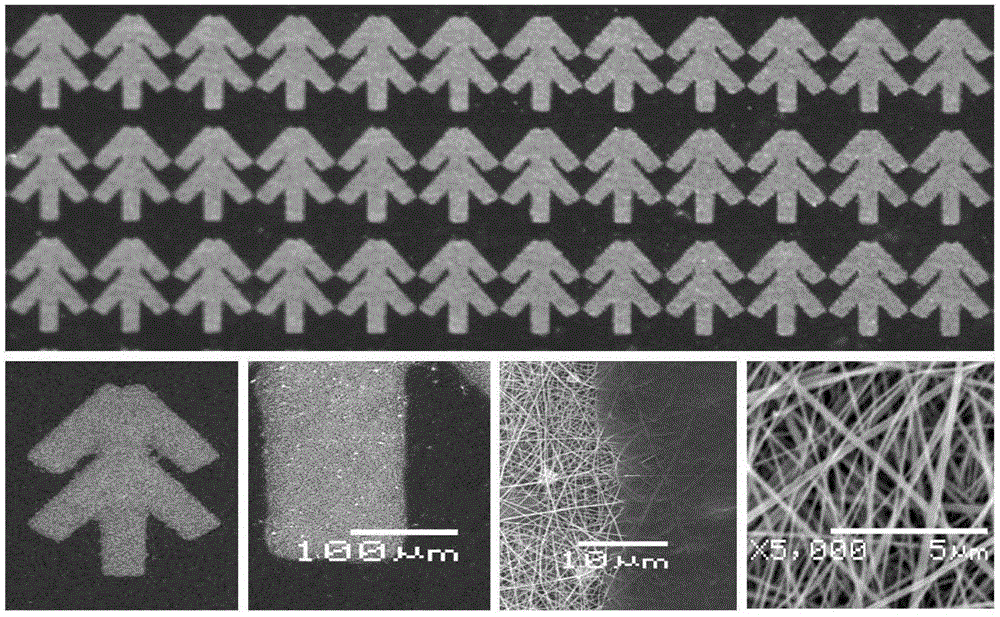

[0032] The electrospinning method can be used to fabricate electrospun arrays. according to figure 1 The process shown is for regionalization of electrospinning, such as using a clean substrate material glass or polymer, coating a layer of SU8 photoresist on a homogenizer, and baking on a hot plate at 85 degrees for 20 minutes; the coated photoresist The glued substrate is placed in a photolithography machine, the surface of the substrate is covered with a patterned mask, and exposed under ultraviolet light with an exposure intensity of 100~500mW / cm 2 , the exposure time is between 10 and 200s, and the pattern is transferred to SU8 glue to form a polymerized area and an unpolymerized area; the substrate coated with photoresist is placed on the aluminum block connected to the ground wire of the high-voltage power supply, and the tip of the syringe needle is ground level and connect the positive pole of the high voltage power supply. Use a syringe pump to push the syringe, so ...

Embodiment 2

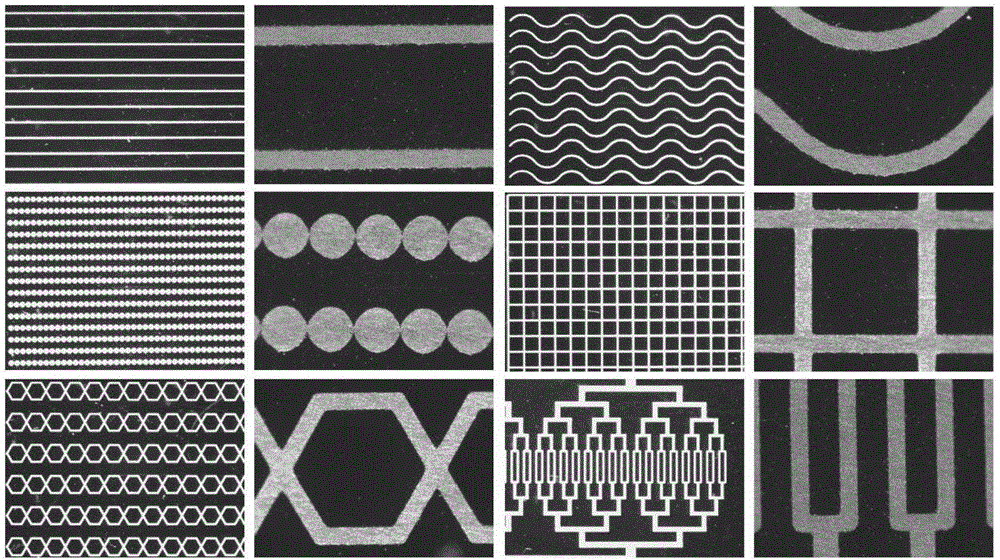

[0035] By designing with different patterns and making mask plates, follow figure 1 The flow shown performs compartmentalization of electrospinning to prepare compartmentalized electrospinning with different patterns, such as image 3 shown.

Embodiment 3

[0037] Electrospinning arrays were prepared for three-dimensional cell culture by regionalized electrospinning. Using the method mentioned in Example 1, PS electrospinning arrays were prepared for three-dimensional cell culture. From Figure 4 It can be seen that the cells can grow for a long time on the regionalized electrospinning, and present a typical three-dimensional growth state. Therefore, multi-parameter and multi-indicator cell culture can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com