Ultraviolet light-emitting diode with transparent zinc oxide base conducting layer and fabrication method of ultraviolet light-emitting diode

A transparent conductive layer, light-emitting diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of chip heating, chip life impact, low LED light extraction efficiency, etc., to achieve uniform current diffusion and reduce the probability of total internal reflection , the effect of improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

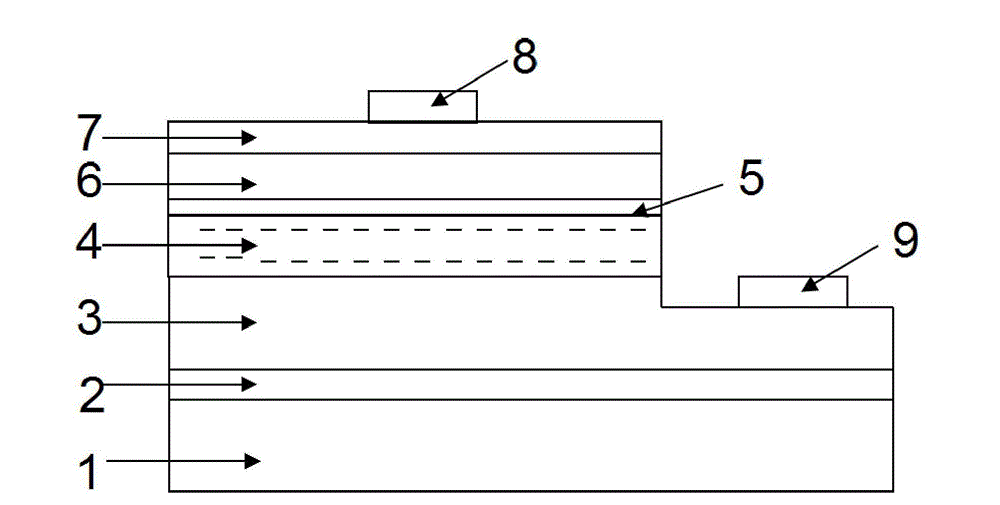

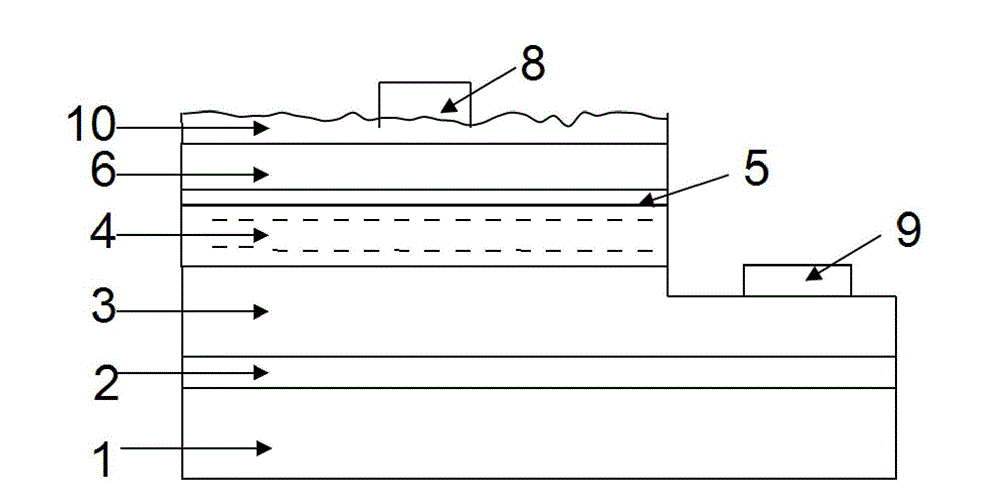

[0028] The ultraviolet light-emitting diode chip with a zinc oxide-based transparent conductive layer of the present invention includes a sapphire substrate 1, an aluminum nitride buffer layer 2, an n-type aluminum gallium nitride layer 3, and an aluminum gallium nitrogen multiquantum well layer connected sequentially from bottom to top. Source layer 4, p-type aluminum gallium nitride electron blocking layer 5, p-type gallium nitride layer 6, zinc oxide-based transparent conductive layer 10, p-type metal electrode 8 on the zinc oxide-based transparent conductive layer 10, n-type aluminum gallium Part of the upper surface of the nitrogen layer 3 is connected to the lower surface of the AlGaN MQW active layer 4 , and an n-type metal electrode 9 is provided in the area not connected to the AlGaN MQW active layer 4 .

[0029] In one emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com