Narrow linewidth excimer laser

An excimer laser, narrow linewidth technology, applied in lasers, phonon exciters, laser parts and other directions, can solve the problems of easy damage of ultraviolet etalon, lower output energy, high energy density, and achieve compact structure, cavity Reduce internal loss and improve the effect of laser energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

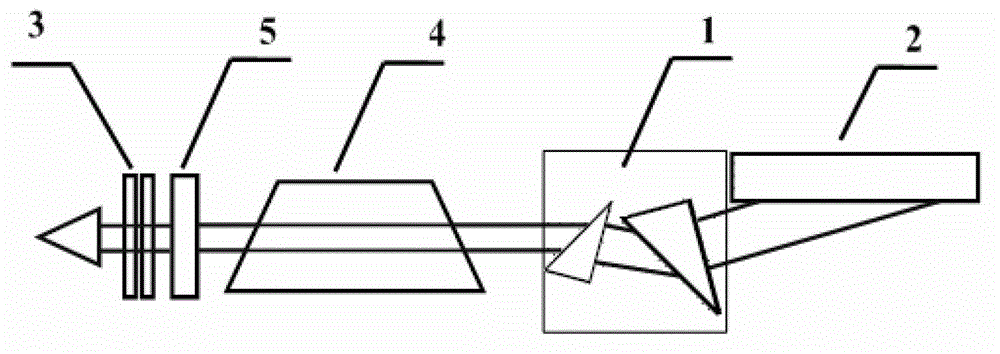

[0015] see figure 1 , figure 1 It is a structural block diagram of the narrow linewidth excimer laser of the present invention. It can be seen from the figure that the narrow linewidth excimer laser of the present invention is composed of a prism beam expander system 1, an ultraviolet grating 2, an ultraviolet etalon 3, a discharge cavity 4 and a coupling output mirror 5, and the positional relationship of the above-mentioned parts is as follows:

[0016] The excimer laser is excited in the discharge cavity 4, and the line width is narrowed by the prism beam expander system 1 and the ultraviolet grating 2. After the narrow line width laser is oscillated and amplified between the ultraviolet grating 2 and the output coupling mirror 5, it is coupled from the output Mirror 5 output. The output narrow-linewidth laser is output through the ultraviolet etalon 3 placed outside the cavity and perpendicular to the optical path, and the laser incident angle of the ultraviolet grating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

| Diffraction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com