Alkali-swellable acrylic emulsions comprising acrylic acid, use thereof in aqueous formulations and formulations containing same

A technology of acrylic and emulsion, which is applied in the direction of medical preparations containing active ingredients, skin care preparations, cosmetic preparations, etc., and can solve problems such as strategic risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

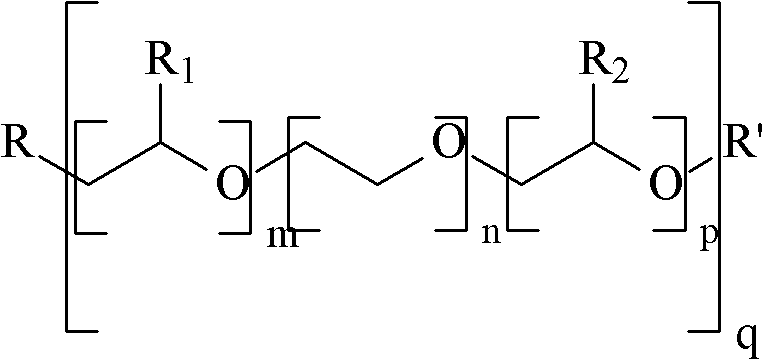

Method used

Image

Examples

Embodiment 1

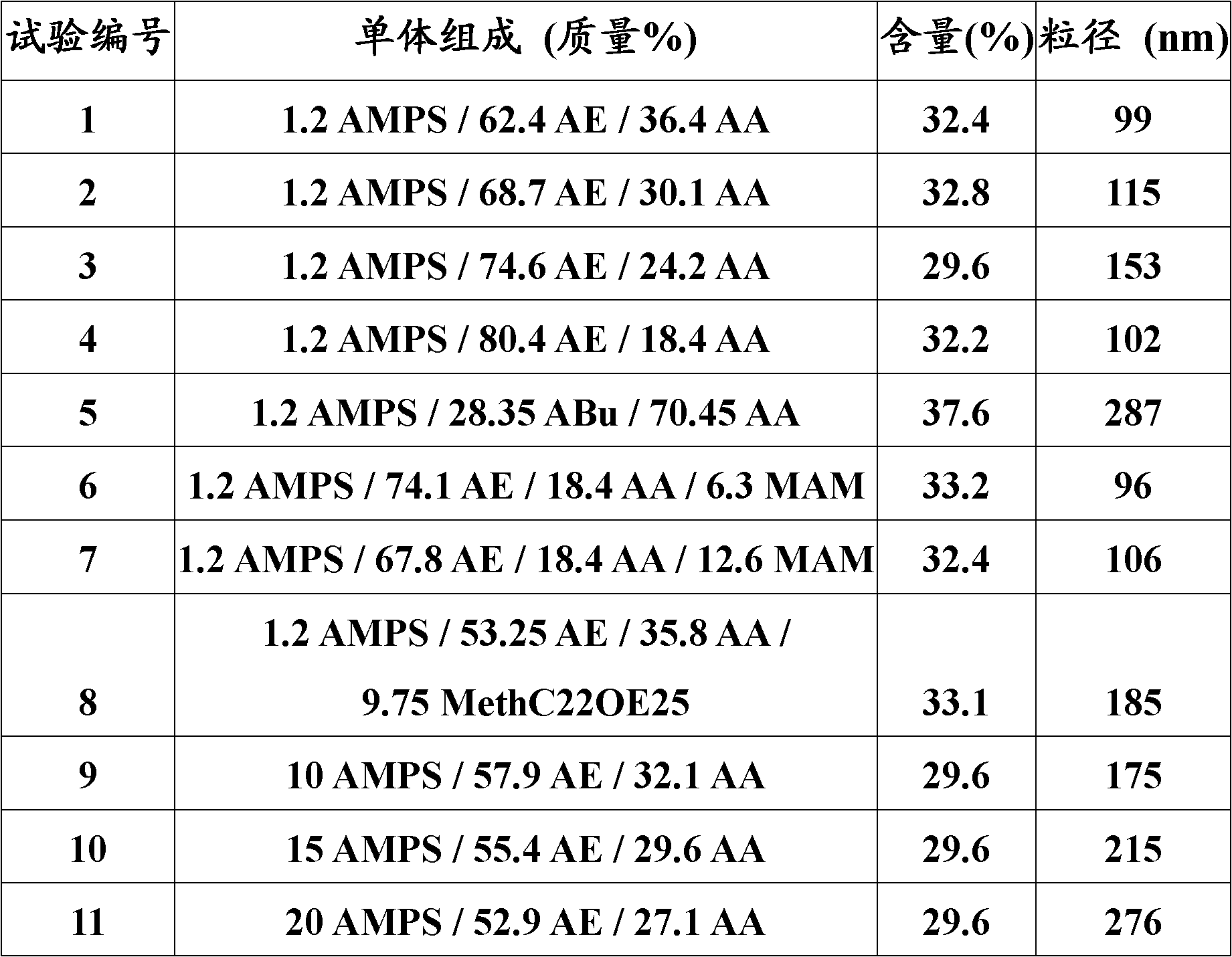

[0077] Test No. 1 according to the invention

[0078] This test concerns the manufacture of an ASE-type emulsion comprising a copolymer consisting of the following monomers expressed in weight percent:

[0079] a) 36.4% acrylic acid,

[0080] b) 62.4% ethyl acrylate,

[0081] c) 1.2% AMPS.

[0082] Add 550 g of secondary deionized water and 7.0 g of AMPS solution (55% AMPS aqueous solution neutralized with sodium hydroxide, produced by LUBRIZOL TM marketed by the company under the name AMPS 2405).

[0083] The medium was heated to 78°C and a catalytic system consisting of 0.96 g of ammonium persulfate dissolved in 10 g of double deionized water and 0.096 g of sodium metabisulfite dissolved in 10 g of double deionized water was added via a funnel.

[0084] Afterwards, 236 g of ethyl acrylate and 85 g of acrylic acid (90%) were added continuously and gradually.

[0085] The temperature of the reaction medium was maintained at 78°C (± 2) throughout the addition.

[0086] O...

Embodiment 2

[0107] This example illustrates the thickening efficacy of an emulsion of the invention used in water such that the active ingredient level is 5% of the dry polymer. When added to water, the medium was neutralized to a pH between 4.9 and 5.5 by adding sodium hydroxide, and the Brookfield of the medium was measured at 25 °C and 100 RPM TM Viscosity, whose values are given in Table 2.

[0108]

[0109] Table 2

[0110] The thickening properties of the produced emulsions were thus demonstrated from the moment they were placed under alkaline conditions.

[0111] Furthermore, the thickening effect at such low pH was unexpectedly noted; typically, ASE and HASE type emulsions thicken in the pH range of 6 to 7.

[0112] "Low pH" thickening is particularly difficult to achieve and is of interest in the cosmetic field where thickening effects in the pH range of the skin (ie between 5 and 6 pH units) are desired. This is reported in document EP 2 027 169 A1.

Embodiment 3

[0114] This example illustrates the use of a commercially available thickening emulsion of the ASE type (with surfactant) and a surfactant-free emulsion according to the present invention in concrete formulations.

[0115] In order to do this, concrete is prepared using techniques well described in the literature, consisting of the following substances:

[0116] -300kg CEM I 52.5N cement;

[0117] -880 large grit 10 / 20;

[0118] -110kg 0 / 4 sand;

[0119] Where the ratio W / C of water to cement is set at 0.5, the following substances are added relative to the dry weight of cement:

[0120] -1.23% by weight of dispersant, by COATEX TM Company under the name Ethacryl TM 1030 sale;

[0121] -1% by weight defoamer, by HUNTSMANN TM Company under the name Empilan TM PF 7169 for sale.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com