Cu-Ni-Si copper alloy plate with excellent deep-draw characteristics and production method thereof

A cu-ni-si, copper alloy plate technology, used in metal/alloy conductors, cable/conductor manufacturing, conductive materials, etc., can solve the problem of insufficient machinability of copper-nickel-silicon alloys, obstacles to raw material application, deep drawing processability Problems such as poor balance of solder heat-resistant peeling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

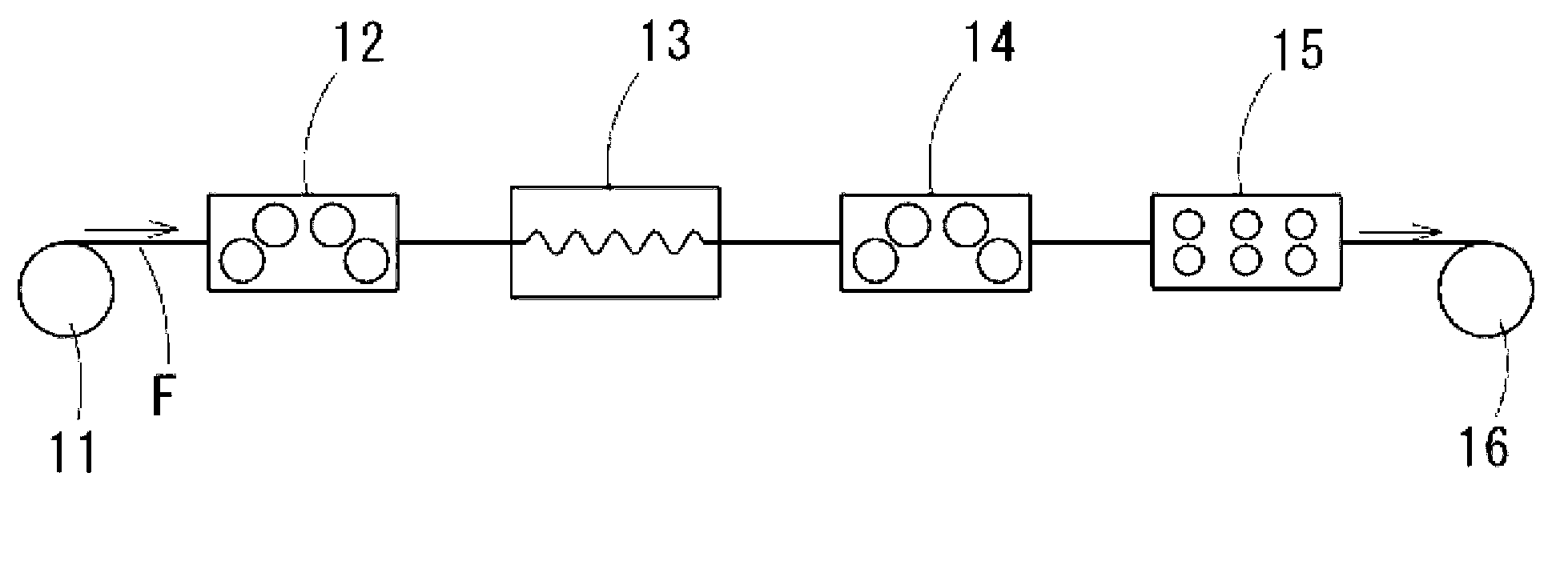

[0088] Materials were prepared so as to have the components shown in Table 1, melted in a low-frequency melting furnace with a reducing atmosphere, and then cast to manufacture a copper alloy ingot with a size of 80 mm in thickness, 200 mm in width, and 800 mm in length. After heating this copper alloy ingot to 900-980 degreeC, the hot-rolled plate of thickness 11mm was formed by hot rolling, and after water-cooling this hot-rolled plate, 0.5 mm flat cutting was performed on both surfaces. Next, cold rolling was performed at a rolling ratio of 87% to produce a cold-rolled sheet with a thickness of 1.3 mm, and continuous annealing was carried out at 710 to 750° C. for 7 to 15 seconds, followed by pickling and surface grinding, and further, Cold rolling was carried out at a rolling ratio of 77% to produce a cold-rolled sheet with a thickness of 0.3 mm.

[0089] After the cold-rolled sheet was kept at 710-780°C for 7-15 seconds, it was rapidly cooled to implement solution treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

| elastic limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap