Preparation method of polyinosinic acid-polycytidylic acid lyophilized powder injection

A technology of polycytidylic acid and polyinosinic acid, which is applied in the field of preparation of polyinosinic acid polycytidylic acid freeze-dried powder injection, can solve the toxic and side effects of oxidative degradation products, easy oxidative degradation, and short validity period To achieve the effect of increasing clinical pharmacological effects, prolonging the validity period, and reducing toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of polyinosinic acid polycytidylic acid freeze-dried powder injection, comprising the following steps:

[0027] (1) Take an appropriate amount of polycytidylic acid and polyinosinic acid, the compatibility ratio of polycytidylic acid and polyinosinic acid is 1:0.8, dissolve them in sterilized normal saline, keep warm at 35°C for half an hour, mix, slowly Stir for 0.5 hour to make polyinosinic acid and polycytidylic acid solution;

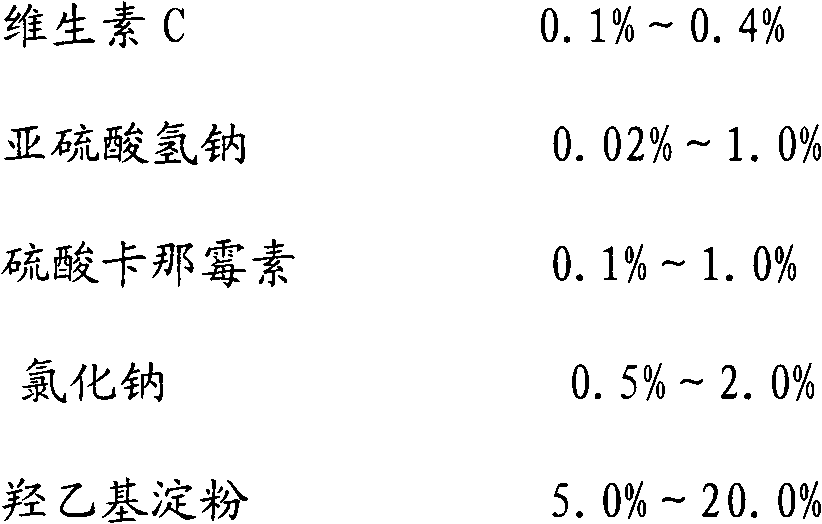

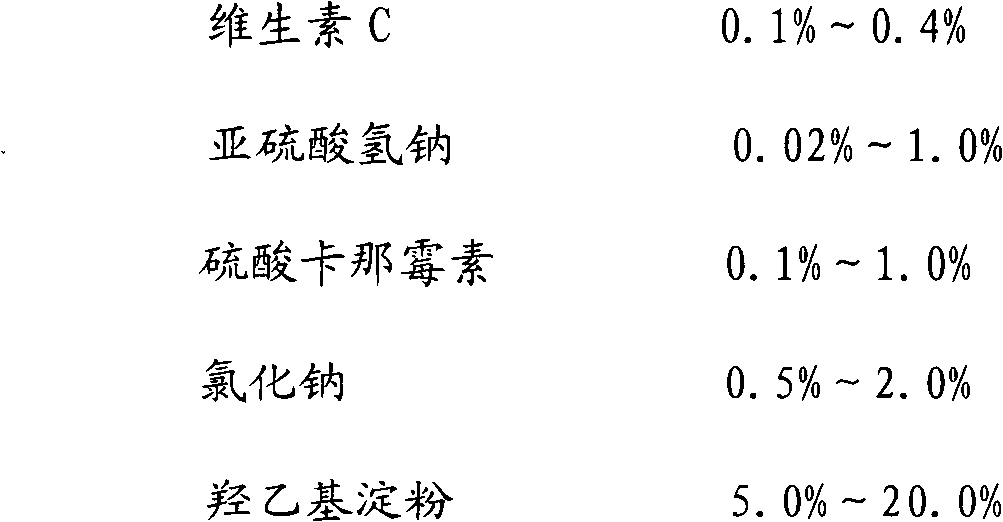

[0028] (2) Dissolve quantitative hydroxyethyl starch, sodium chloride, vitamin C, kanamycin sulfate, and sodium bisulfite in distilled water, adjust the pH value to 7.2-7.4, filter, sterilize, and cool to 5°C , dissolved in polyinosinic acid polycytidylic acid solution, so that the content of vitamin C is 0.1%, the content of sodium bisulfite is 0.02%, the content of kanamycin sulfate is 0.1%, and the content of sodium chloride is 0.5%. The content of hydroxyethyl starch is 5.0%;

[0029] (3) Filter with a 0.22 μm filte...

Embodiment 2

[0032] A preparation method of polyinosinic acid polycytidylic acid freeze-dried powder injection, comprising the following steps:

[0033] (1) Take an appropriate amount of polycytidylic acid and polyinosinic acid, the compatibility ratio of polycytidylic acid and polyinosinic acid is 1:1.2, dissolve them in sterilized normal saline, keep warm at 45°C for half an hour, mix, slowly Stir for 1.5 hours to make a polyinosinic acid polycytidylic acid solution;

[0034] (2) Dissolve quantitative hydroxyethyl starch, sodium chloride, vitamin C, kanamycin sulfate, and sodium bisulfite in double-distilled water, adjust the pH value to 7.2-7.4, filter, sterilize, and cool to 5 ℃, dissolved in polyinosinic acid polycytidylic acid solution, so that the content of vitamin C is 0.2%, the content of sodium bisulfite is 0.1%, the content of kanamycin sulfate is 0.15%, and the content of sodium chloride is 0.9%. , The content of hydroxyethyl starch is 10.0%.

[0035] (3) Filter with a 0.22 ...

Embodiment 3

[0038] A preparation method of polyinosinic acid polycytidylic acid freeze-dried powder injection, comprising the following steps:

[0039] (1) Take an appropriate amount of polycytidylic acid and polyinosinic acid, the compatibility ratio of polycytidylic acid and polyinosinic acid is 1:1.8, dissolve them in sterilized normal saline, keep warm at 55°C for half an hour, mix, slowly Stir for 1.0 hour, add kanamycin sulfate, make the content of kanamycin sulfate be 0.12%, make polyinosinic acid polycytidylic acid solution;

[0040] (2) Dissolve quantitative hydroxyethyl starch, sodium chloride, vitamin C, kanamycin sulfate, and sodium bisulfite in double-distilled water, adjust the pH value to 7.2-7.4, filter, sterilize, and cool to 5 ℃, dissolved in polyinosinic acid polycytidylic acid solution, so that the content of vitamin C is 0.35%, the content of sodium bisulfite is 0.8%, the content of kanamycin sulfate is 0.12%, and the content of sodium chloride is 0.8%. , The content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com