Preparation for glipizide compression-coated controlled-release tablets

A technology for glipizide and coated tablets, which is applied in the field of glipizide compression-coated controlled-release tablets, can solve the problems of unfavorable large-scale production, cumbersome process and high cost, and achieves improvement of peristaltic promotion effect and maintenance of blood medicine. effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

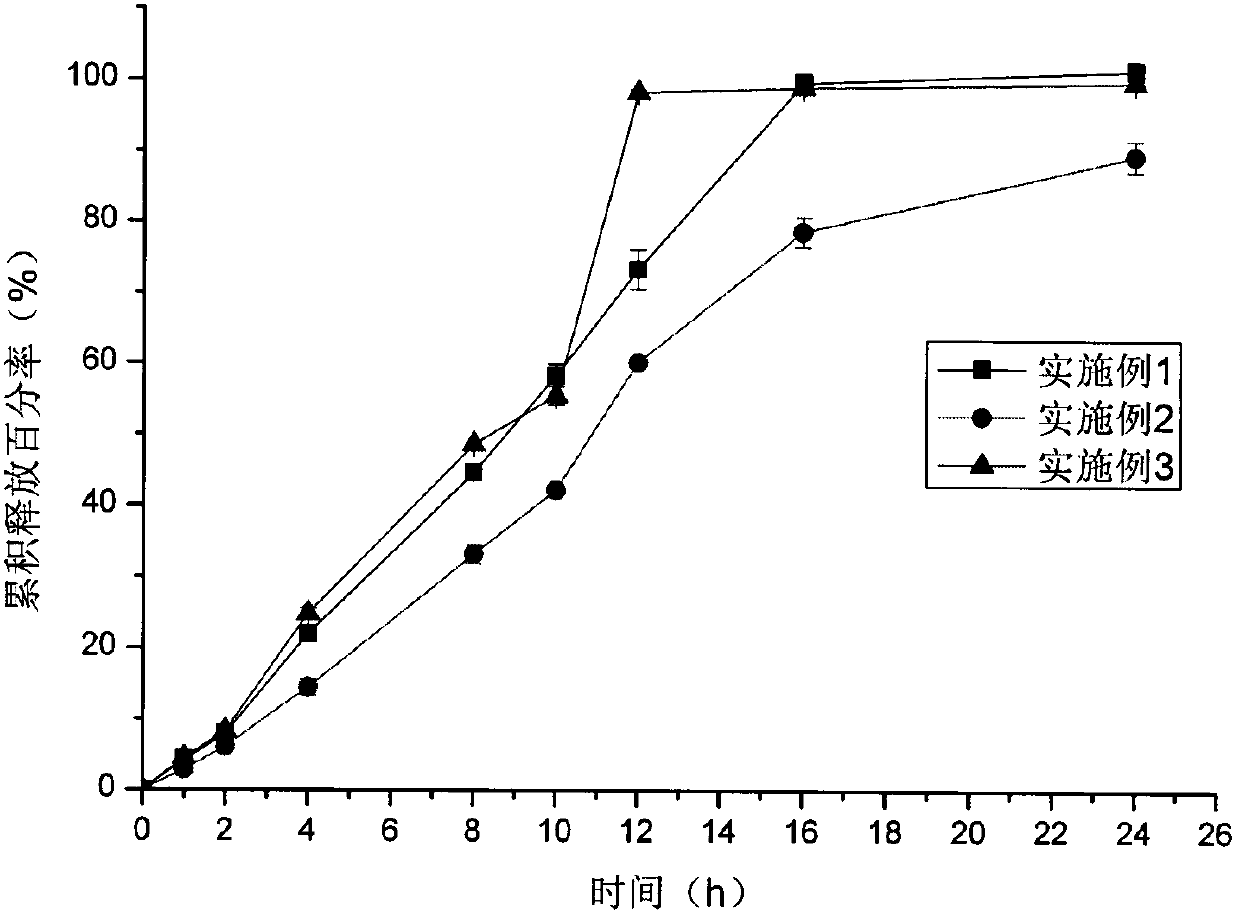

Embodiment 1

[0028] Chip

[0029]

[0030]The above-mentioned raw materials (excluding magnesium stearate) are uniformly mixed, dried at 60°C after granulation, sieved and granulated, and then magnesium stearate is added and mixed evenly. Tablets were compressed with a single-punch tablet machine under a pressure of 30N to form core tablets (diameter=7mm) each weighing 94.5 mg. Shell

[0031]

[0032] The above-mentioned raw materials (excluding magnesium stearate) are uniformly mixed, dried at 60°C after granulation, sieved and granulated, and then magnesium stearate is added and mixed evenly. Dry-coating machine (Kikusui Cleanpress Corret 18DC) tableting under 90N pressure, the shell layer and pre-prepared tablet core were combined to form compression-coated tablets (diameter=9mm) containing glipizide 5mg each weighing 400mg .

Embodiment 2

[0034] Chip

[0035]

[0036] The above-mentioned raw materials (excluding magnesium stearate) are uniformly mixed, dried at 60°C after granulation, sieved and granulated, and then magnesium stearate is added and mixed evenly. Tablets were compressed with a single-punch tablet machine under a pressure of 30N to form core tablets (diameter=7mm) each weighing 112 mg.

[0037] Shell

[0038]

[0039] The above-mentioned raw materials (excluding magnesium stearate) are uniformly mixed, dried at 60°C after granulation, sieved and granulated, and then magnesium stearate is added and mixed evenly. Dry-coating machine (Kikusui Cleanpress Corret 18DC) tableting under 90N pressure, the shell layer and pre-prepared tablet core were combined to form a press-coated tablet (diameter=9mm) containing glipizide 5mg each weighing 410mg .

Embodiment 3

[0041] Chip

[0042]

[0043] The above-mentioned raw materials (excluding magnesium stearate) are uniformly mixed, dried at 60°C after granulation, sieved and granulated, and then magnesium stearate is added and mixed evenly. Tablets were compressed with a single-punch tablet machine under a pressure of 30N to form core tablets (diameter=7mm) each weighing 187 mg.

[0044] Shell

[0045]

[0046] The above-mentioned raw materials (excluding magnesium stearate) are uniformly mixed, dried at 60°C after granulation, sieved and granulated, and then magnesium stearate is added and mixed evenly. Dry-coating machine (Kikusui Cleanpress Corret 18DC) tableting under 90N pressure, the shell layer and pre-prepared tablet core were combined to form compression-coated tablets (diameter=9mm) containing glipizide 5mg each weighing 480mg .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com