Starch-hyaluronic acid hemostatic agent and preparation method thereof

A technology of hyaluronic acid and hemostatic agent, which is applied in the field of medical devices, can solve problems such as unsatisfactory effects, inflammatory reactions, burns, etc., and achieve the effects of abundant output, wide sources, and various types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

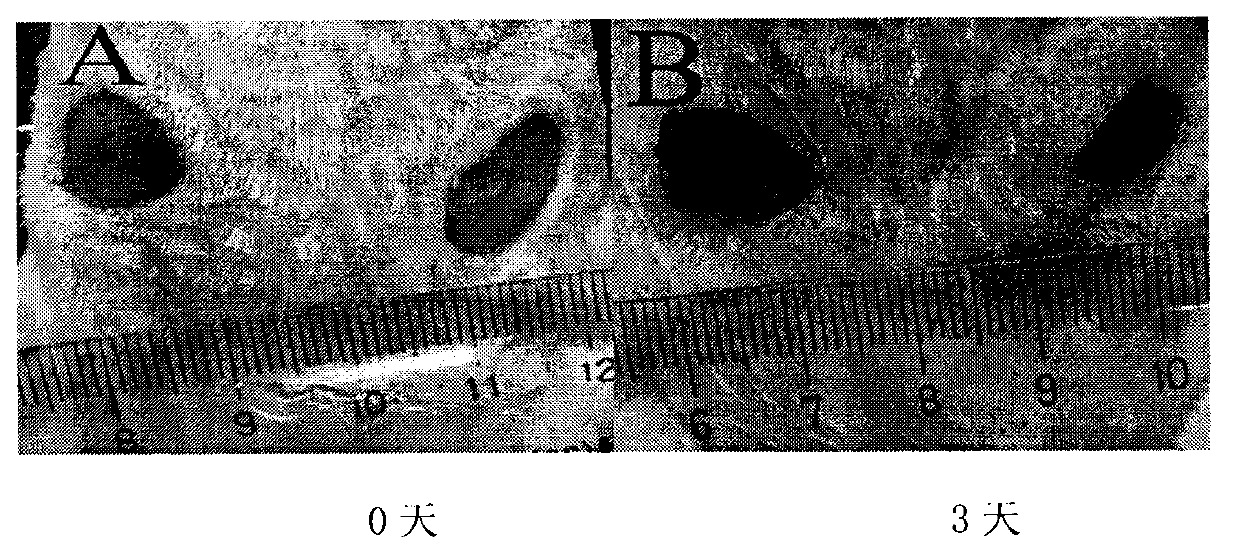

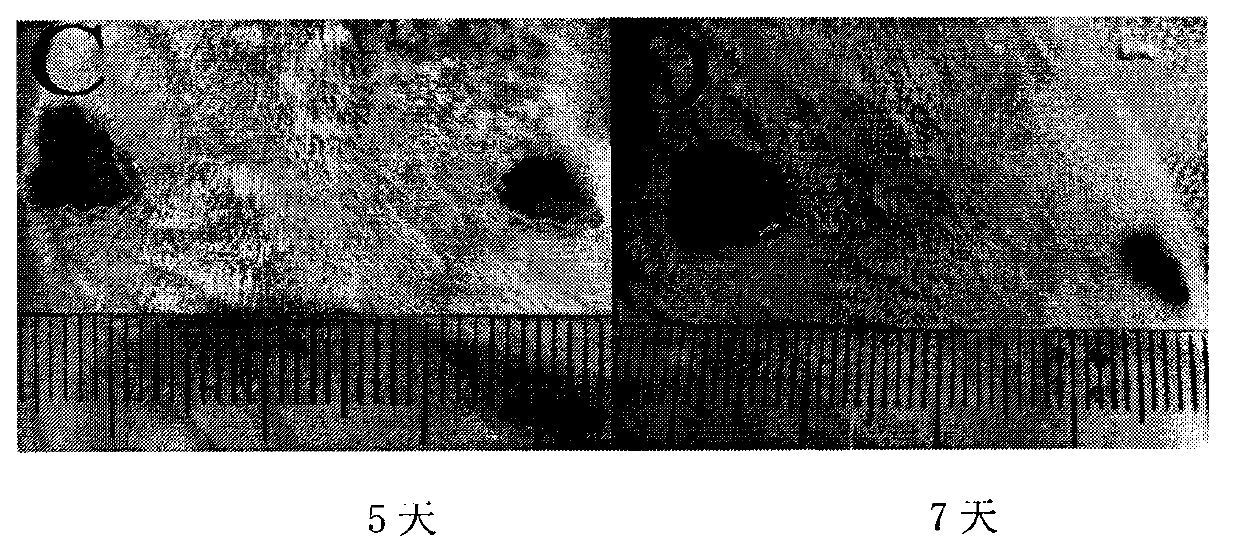

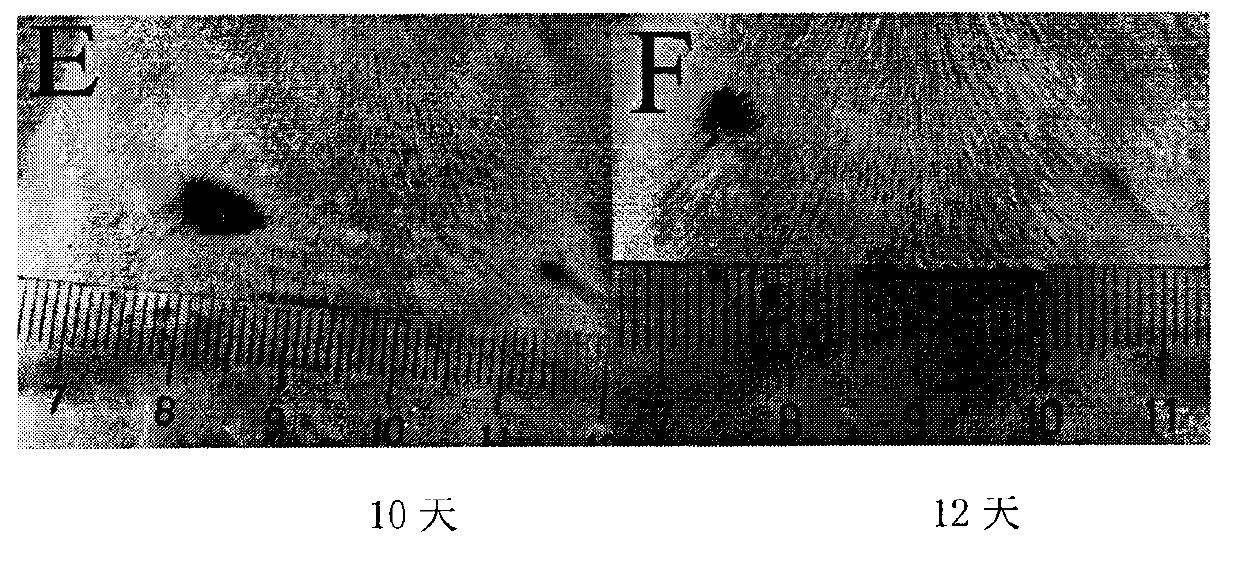

Image

Examples

Embodiment 1

[0015] Preparation of starch-hyaluronic acid hemostatic agent

[0016] Put 2kg of starch in a reaction tank, add 5 L of 4% (W / V) hyaluronic acid aqueous solution, turn on the stirrer, and heat to 55 ℃ ± 5 ℃, make starch fully swell to form a uniform solution, filter, add Potassium sulfate was used as an initiator in an amount of 0.1% (W / V). Continue to stir for 4h to obtain starch-hyaluronic acid reaction solution. Add the reaction solution to the material hopper of the spray dryer, set the inlet air temperature to 130°C ± 2°C, the atomization frequency to 700.0 rpm, and the constant current pump speed to 12 rpm. Turn on the spray dryer, start the induced draft fan, start heating, and wait for the air to come out. The temperature is 90℃±2℃, and the temperature of the inlet and outlet of the system is basically stable. The spray-dried material was collected to obtain 1.4 kg of starch-hyaluronic acid porous microspheres with a yield of 70%.

[0017] The starch-hyaluronic acid...

Embodiment 2

[0019] Preparation of starch-hyaluronic acid hemostatic agent

[0020] Put 2kg of starch in a reaction tank, add 5 L of 5% (W / V) hyaluronic acid aqueous solution, turn on the stirrer, and heat to 50 ° C ± 5 ° C, so that the starch is fully swollen to form a uniform solution, filtered, added Potassium sulfate was used as an initiator in an amount of 0.05% (W / V). Continue to stir for 4h to obtain starch-hyaluronic acid reaction solution. Add the reaction solution to the material hopper of the spray dryer, set the inlet air temperature to 130°C ± 2°C, the atomization frequency to 700.0 rpm, and the constant current pump speed to 12 rpm. Turn on the spray dryer, start the induced draft fan, start heating, and wait for the air to come out. The temperature is 90℃±2℃, and the temperature of the inlet and outlet of the system is basically stable. The spray-dried material was collected to obtain 1.5 kg of starch-hyaluronic acid porous microspheres with a yield of 75%.

[0021] The s...

Embodiment 3

[0023] Preparation of starch-hyaluronic acid hemostatic agent

[0024] Put 2kg of starch in a reaction tank, add 5L of 3% (W / V) hyaluronic acid aqueous solution, turn on the stirrer, and heat to 55 ° C ± 5 ° C, so that the starch is fully swollen to form a uniform solution, filtered, added Potassium sulfate was used as an initiator in an amount of 0.05% (W / V). Continue to stir for 4h to obtain starch-hyaluronic acid reaction solution. Add the reaction solution to the material hopper of the spray dryer, set the inlet air temperature to 130°C ± 2°C, the atomization frequency to 700.0 rpm, and the constant current pump speed to 12 rpm. Turn on the spray dryer, start the induced draft fan, start heating, and wait for the air to come out. The temperature is 90℃±2℃, and the temperature of the inlet and outlet of the system is basically stable. The spray-dried material was collected to obtain 1.3 kg of starch-hyaluronic acid porous microspheres with a yield of 70%.

[0025] The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com