Catalyst for preparing 1, 1, 1, 2, 3, 3, 3-heptafluoropropane as well as preparation method and applications thereof

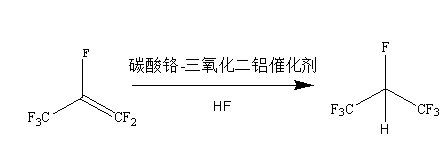

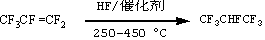

A technology of heptafluoropropane and catalyst, which is applied in the field of chromium carbonate-containing catalyst and its preparation, which can solve the problems of large equipment investment, high product cost, and long reaction time, and achieve the effects of short residence time, fast reaction speed, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

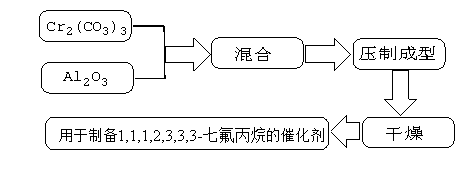

[0027] Embodiment 1: preparation catalyst A

[0028] 50 g of Cr was mechanically mixed 2 (CO 3 ) 3 and 500 g Al 2 o 3 Mix evenly, then add 275 mL of absolute ethanol and mix well, put it into a catalyst preparation device and press it into catalyst particles, dry it in a constant temperature drying oven at 150°C for 12 hours, take it out to get catalyst A, and put it in a desiccator for later use.

Embodiment 2

[0029] Embodiment 2: preparation catalyst B

[0030] 275 g Cr was mechanically mixed 2 (CO 3 ) 3 and 275 g Al 2 o 3 Mix evenly, then add 275 mL of absolute ethanol and mix evenly, put it into a catalyst preparation device and press it into catalyst particles, dry it in a constant temperature drying oven at 140°C for 20 hours, take it out to get catalyst B, and put it in a dryer for later use.

Embodiment 3

[0031] Embodiment 3: preparation catalyst C

[0032] According to the method of embodiment 1, take by weighing 500 g Cr 2 (CO 3 ) 3 , 50 g Al 2 o 3 , mechanically mix evenly, add 275 mL of absolute ethanol to mix, put it into a catalyst preparation device and press it into catalyst particles, dry it in a constant temperature drying oven at 160°C for 10 hours, take it out to get catalyst C, and put it in a desiccator for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com