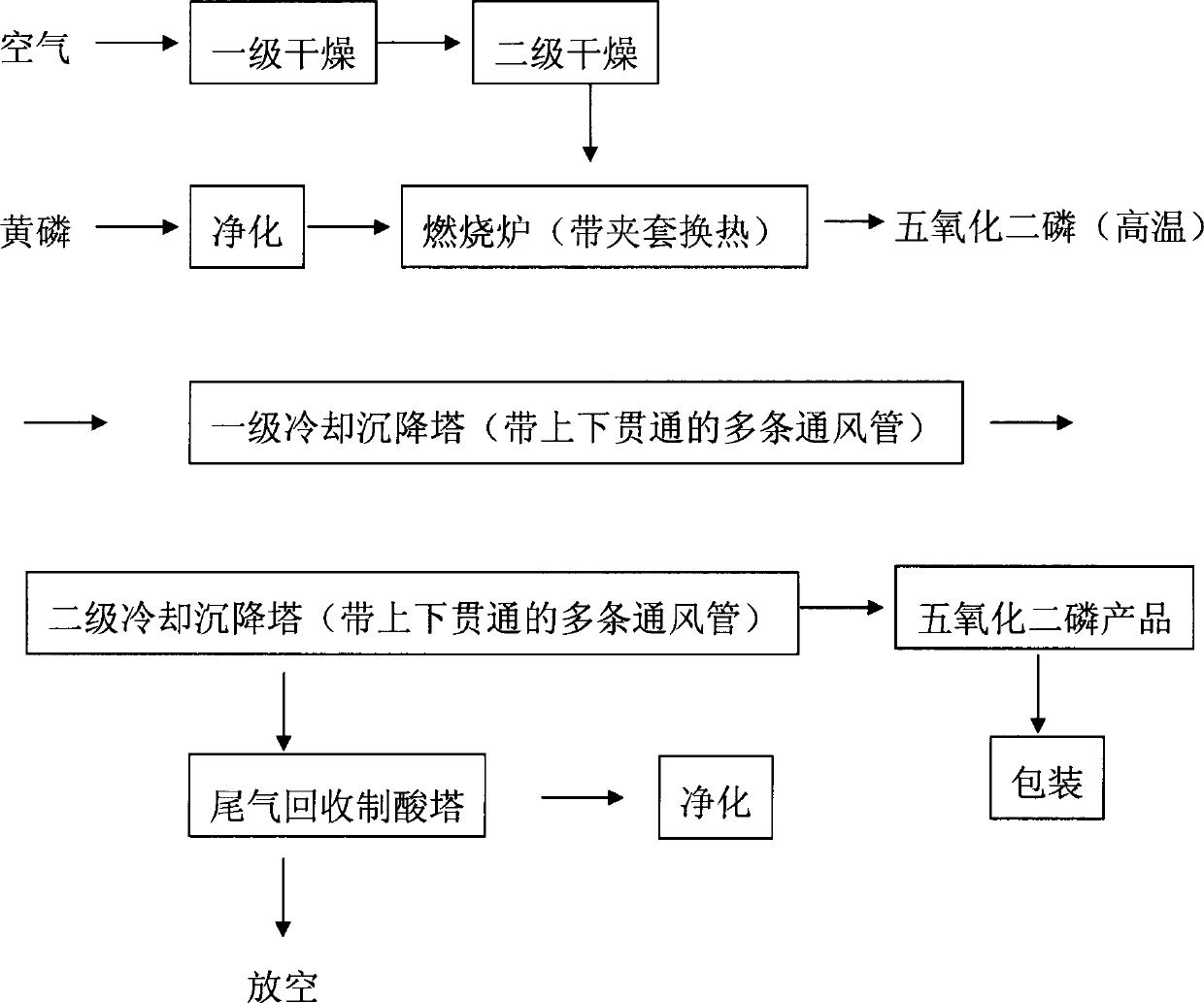

Phosphorus pentoxide reinforced air cooling production method and equipment

A technology for phosphorus pentoxide and production equipment, applied in the direction of phosphorus oxides and other directions, can solve the problems of high cost, large equipment investment and low output, and achieve the effects of high cost, large equipment investment and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

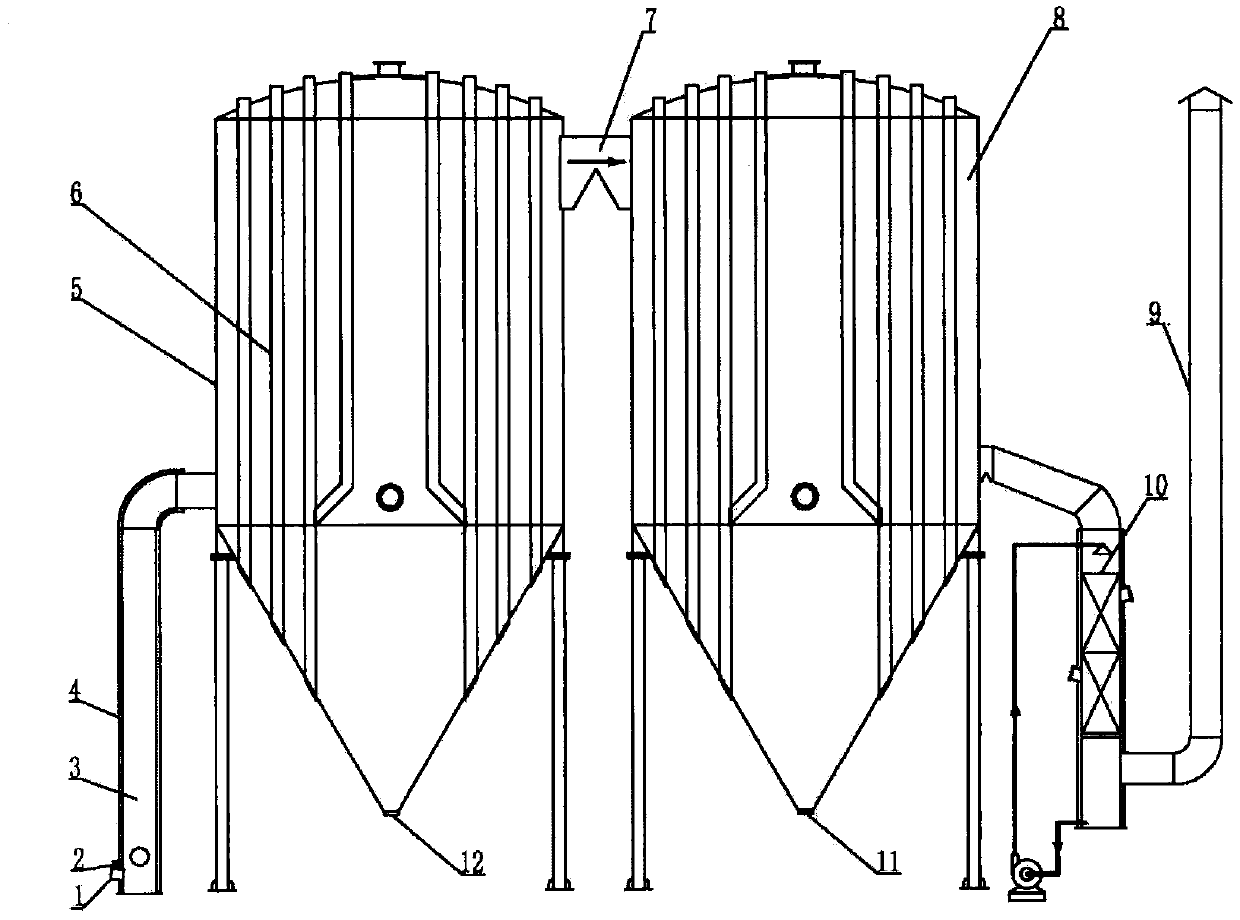

Method used

Image

Examples

Embodiment 1

[0029]The yellow phosphorus flows into the combustion furnace for combustion at a flow rate of 150 kg per hour. The selected fan is a 9-26-5A high-pressure centrifugal fan (rated air volume is 6349 cubic meters per hour), and the actual input of dry air is about 5000 cubic meters. 150 kg of yellow phosphorus needs about 200 kg of oxygen, and the input of 5000 cubic meters of dry air contains about 1200 kg of oxygen, that is, the amount of raw materials used in the production process is carried out according to the oxygen-enriched operation (about 1:6). . The production temperature of the combustion furnace is controlled at 500°C to 900°C, the inlet temperature of the circulating cooling water is 40°C to 50°C, the outlet temperature is 85°C to 95°C, and the continuous combustion is 20 to 40 hours each time, and the continuous production is assessed for one month. The operation is stable, and there are no phenomena such as equipment burning red, pipe blockage, thick smoke from t...

Embodiment 1 5

[0030] Embodiment 1 phosphorus pentoxide product quality:

[0031] Indicator name

[0032] The quality after the purified phosphoric acid of embodiment 1 gained is as follows:

[0033] Indicator name

[0034] Sulfate (as SO 4 2- count),%

Embodiment 2

[0036] The yellow phosphorus flows into the combustion furnace for combustion at a flow rate of 200 kg per hour. The selected fan is still a 9-26-5A high-pressure centrifugal fan (rated air volume is 6349 cubic meters per hour), and the actual input of dry air is about 5000 cubic meters per hour. Burning 200 kilograms of yellow phosphorus requires about 260 kilograms of oxygen, and the input 5000 cubic meters of dry air contains about 1200 kilograms of oxygen, and the oxygen enrichment ratio (about 1:4.6) used in the production process is slightly smaller. The production temperature of the combustion furnace is controlled at 600°C to 1000°C, the inlet temperature of the circulating cooling water is 40°C to 50°C, the outlet water temperature is 85°C to 98°C, and the continuous combustion is 20 to 40 hours each time, and the continuous production is 7 days for assessment and equipment operation Stable, there is no phenomenon such as equipment burning red, pipe blockage, chimney s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com