Graphene with high specific capacitance and preparation method thereof

A technology of high specific capacitance and graphene, applied in the direction of graphene, nano-carbon, etc., can solve the problems of easy aggregation, low quality of graphene, low yield, etc., to overcome the difficulty of separation, simplify the operation process, and overcome the problems of low purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

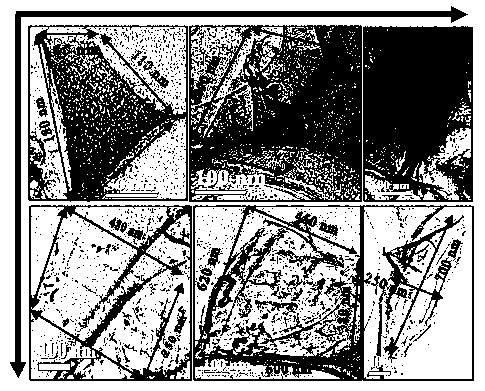

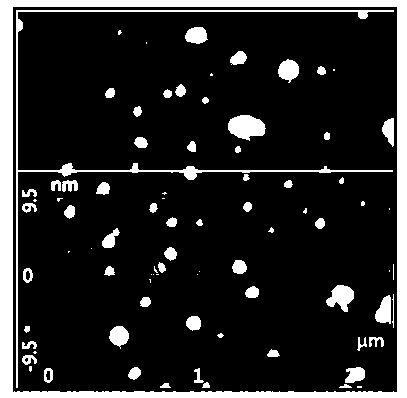

Embodiment 1

[0039] Add 1.45 g of sucrose to a solution of 3.5 ml of water, 100 μl of concentrated sulfuric acid and 20 mg of nickel nitrate to dissolve, then 2 g of MCM-22 molecular sieves, stir at room temperature, and dry at 100 °C and 160 °C for 12 hours, then Then add a mixed solution of 0.87 g sucrose, 3.5 ml water, 20 mg nickel nitrate and 60 μl concentrated sulfuric acid, mix well, and then dry at 100 °C and 160 °C for 12 h, put the obtained solid powder into a vacuum tube furnace, pass Nitrogen gas was roasted at 500 °C for 2 h, then taken out, put into 2.5 L of mixed solution of hydrofluoric acid and hydrochloric acid, wherein the concentration of hydrofluoric acid was 0.1 g / ml, and the concentration of hydrochloric acid was 0.3 g / ml, after stirring at 70 °C for 2 h, Centrifuge, wash the solid with water and sonicate, and finally freeze-dry the obtained solid sample to obtain graphene powder. The graphene powder contains 1-4 layers of graphene with a two-dimensional size in the r...

Embodiment 2

[0046] Add 1.0 g of sucrose to a solution of 3.5 ml of water, 100 μl of concentrated sulfuric acid and 20 mg of nickel sulfate to dissolve it, then add 2 g of MCM-22 molecular sieves, stir evenly at room temperature, and dry at 60 °C and 150 °C for 12 hours respectively. Then add a mixed solution of 1.0 g sucrose, 3.5 ml water, 20 mg nickel sulfate and 60 μl concentrated sulfuric acid, mix well, then dry at 100 °C and 160 °C for 12 hours, and put the obtained solid powder into a vacuum tube furnace , roasted at 1200 °C for 2 h under nitrogen gas, took it out, put it into a mixed solution of 2.5 L of hydrofluoric acid and hydrochloric acid, wherein the concentration of hydrofluoric acid was 0.3 g / ml, and the concentration of hydrochloric acid was 0.3 g / ml, and stirred at 20 °C for 3 h Afterwards, centrifugal separation, the solid was washed with water and ultrasonicated, and the finally obtained solid sample was freeze-dried to obtain graphene powder. The graphene powder contai...

Embodiment 3

[0048] Add 2.05 g of sucrose to a solution of 3.5 ml of water, 100 μl of concentrated sulfuric acid and 20 mg of nickel chloride to dissolve it, then add 2 g of MCM-22 molecular sieves, stir well at room temperature, and dry at 100 °C and 200 °C for 12 hours each , and then add a mixed solution of 1.27 g sucrose, 3.5 ml water, 20 mg nickel chloride and 60 μl concentrated sulfuric acid, mix well, then dry at 100 °C and 160 °C for 12 hours, and put the obtained solid powder into a vacuum tube In the furnace, blow nitrogen at 800 °C for 2 hours, take it out, put it into a mixed solution of 2.5 L of hydrofluoric acid and hydrochloric acid, wherein the concentration of hydrofluoric acid is 0.2 g / ml, and the concentration of hydrochloric acid is 0.3 g / ml, and stir at 80 °C After 2 h, it was centrifuged, the solid was washed with water and ultrasonicated, and finally the obtained solid sample was freeze-dried to obtain graphene powder. The graphene powder contains 1-10 layers of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com