Biofuel oil-resistant fluorine rubber composition

A technology of fluororubber and fuel oil, which is applied in the field of fluororubber compositions resistant to biofuel oil, can solve the problems of small compression set, reduction of rubber strength and other mechanical properties, achieve low compression deformation rate, improve wear resistance, The effect of low lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The formula table of the fluorine rubber of this embodiment is as follows:

[0023]

[0024] The main components of biofuel are as follows:

[0025] 1. Biogasoline

[0026] 1. Bioethanol is the mainstream, and about 95% of ethanol production is bioethanol;

[0027] 2. ETBE (C 2 H 5 OC 4 H 9 ), manufactured from ethanol and isobutylene.

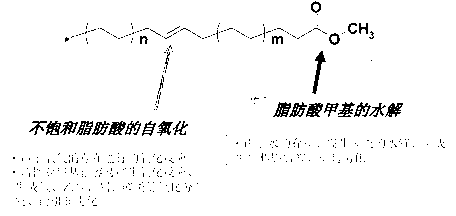

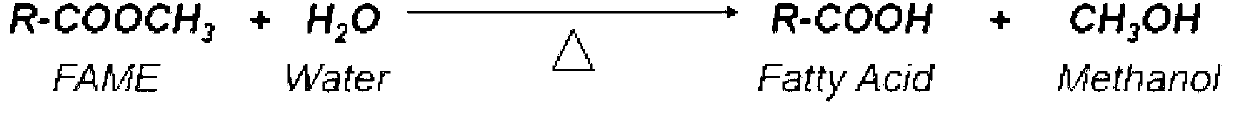

[0028] 2. Biodiesel

[0029] 1. Fatty acid methyl ester is the mainstream, and general biodiesel is fatty acid methyl ester

[0030] 2. BLT, a liquid fuel synthesized by gasification of biological fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com