Method for preparing titanium dioxide nano tip array film for field emission

A titanium dioxide, nano-tip technology, applied in the field of nano-materials, can solve the problems of unsatisfactory results, and achieve the effects of increasing field emission performance, reducing preparation costs and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

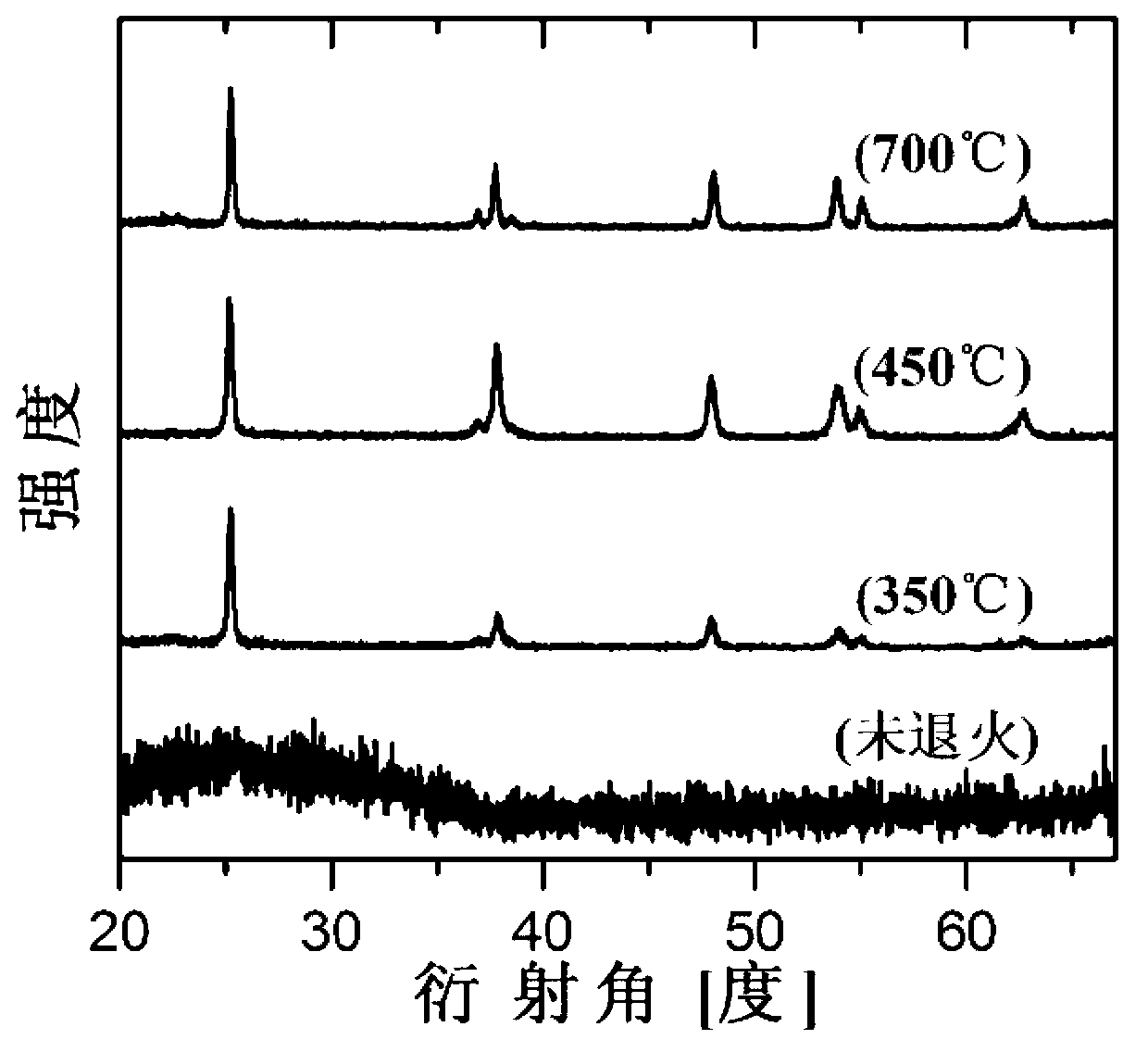

Embodiment 1

[0033] 1. Pretreatment of titanium flakes

[0034] Sonicate the titanium sheet with acetone, alcohol, and deionized water for 15 minutes each, and set aside.

[0035] 2. Preparation of electrolyte

[0036] The electrolytic solution uses ethylene glycol as a solvent, to which 0.25% (mass percentage) of ammonium fluoride and 0.6% (volume percentage) of water are added.

[0037] 3. First Anodizing

[0038] Put the titanium sheet on the positive electrode, put it into the electrolyte solution prepared in step 2, use graphite as the negative electrode, anodize at 60V for 60h, and age the solution. Then, another titanium sheet was put in and anodized at 60V for 24h to obtain a titanium dioxide nanotube array.

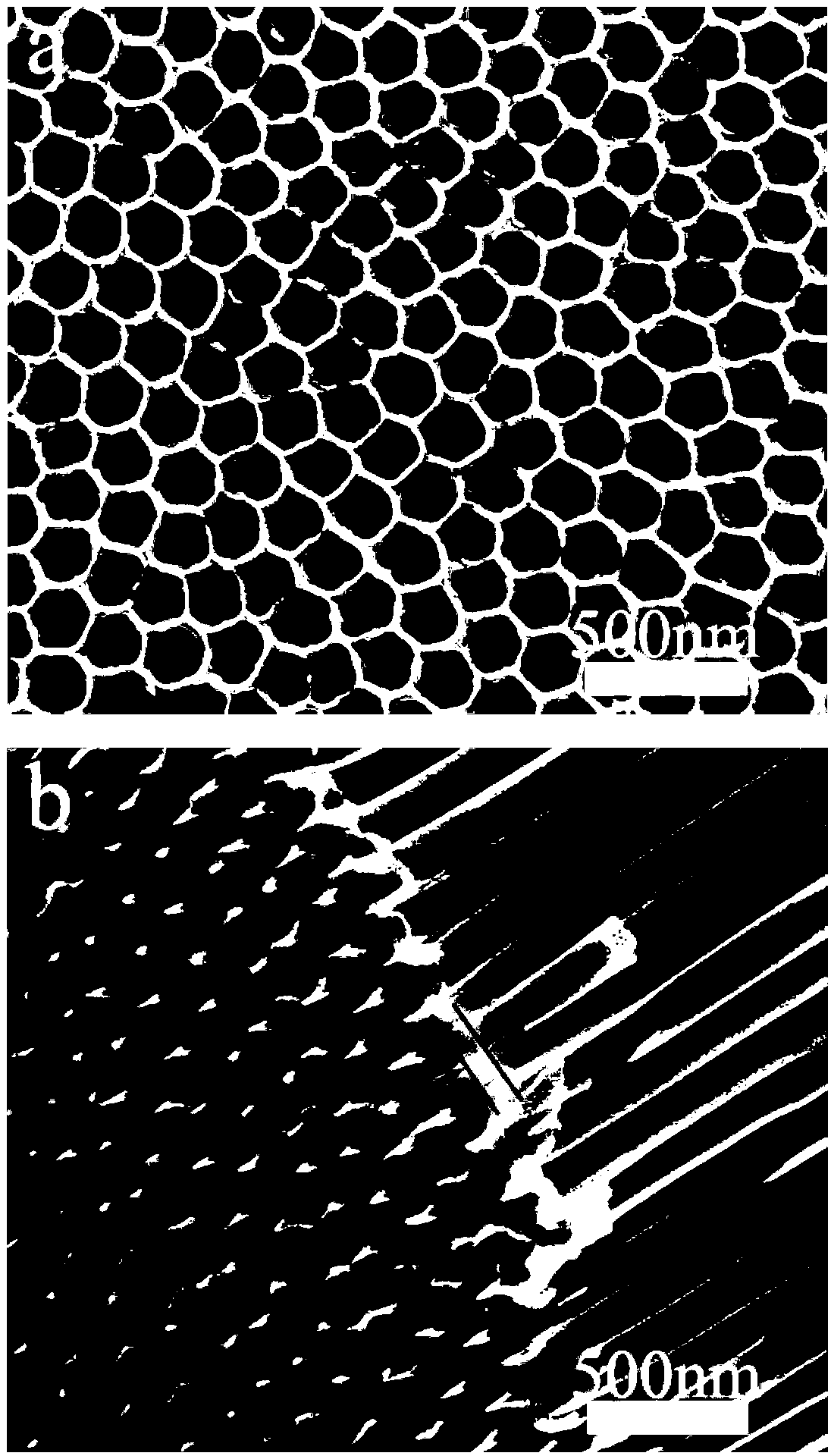

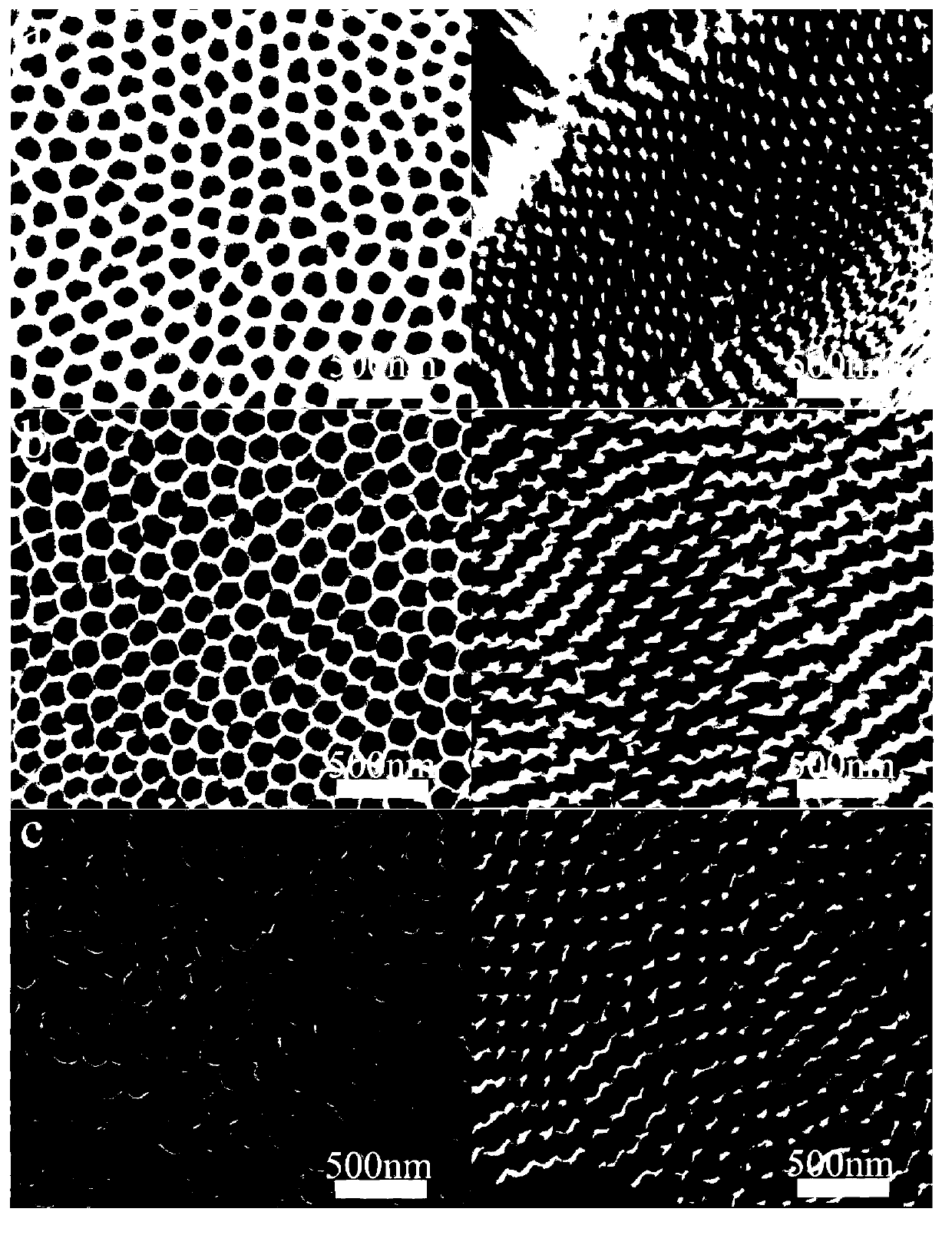

[0039] 4. Ultrasound

[0040] Take out the titanium sheet with the titanium dioxide nanotube array grown in step 3, and wash it with deionized water, and then put it into an ultrasonic instrument to concentrate the ultrasound until the titanium dioxide nanotube array in s...

Embodiment 2

[0048] 1. Pretreatment of titanium flakes

[0049] Sonicate the titanium sheet with acetone, alcohol, and deionized water for 10 min each, and set aside.

[0050] 2. Preparation of electrolyte

[0051] The electrolytic solution uses ethylene glycol as a solvent, to which 0.25% (mass percentage) of ammonium fluoride and 0.8% (volume percentage) of water are added.

[0052] 3. First Anodizing

[0053] Install the titanium sheet on the positive electrode, put it into the electrolyte solution prepared in step 2, use the Pt electrode as the negative electrode, anodize at 60V for 36h, and age the solution. Then, another titanium sheet was put in and anodized at 60V for 12h to obtain a titanium dioxide nanotube array.

[0054] 4. Ultrasound

[0055] Take out the titanium sheet with the titanium dioxide nanotube array grown in step 3, and wash it with deionized water, and then put it into an ultrasonic instrument to concentrate the ultrasound until the titanium dioxide nanotube ar...

Embodiment 3

[0063] 1. Pretreatment of titanium flakes

[0064] Sonicate the titanium sheet with acetone, alcohol, and deionized water for 20 minutes each, and set aside.

[0065] 2. Preparation of electrolyte

[0066] The electrolytic solution uses ethylene glycol as a solvent, to which 0.25% (mass percentage) of ammonium fluoride and 1% (volume percentage) of water are added.

[0067] 3. First Anodizing

[0068] Install the titanium sheet on the positive electrode, put it into the electrolyte solution prepared in step 2, use graphite as the negative electrode, anodize at 60V for 48 hours, and age the solution. Then, another titanium sheet was put in and anodized at 60V for 18h to obtain a titanium dioxide nanotube array.

[0069] 4. Ultrasound

[0070] Take out the titanium sheet with the titanium dioxide nanotube array grown in step 3, and wash it with deionized water, and then put it into an ultrasonic instrument to concentrate the ultrasound until the titanium dioxide nanotube arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com