Method for measuring contents of methanol, sec-butyl alcohol, sesamol and musk xylene in additive for cigarette

A technology for xylene musk and tobacco additives, which is applied to the determination of methanol, xylene musk content in tobacco additives, sesamol, and sec-butanol, can solve problems such as imperfections, and achieve accuracy assurance, accurate testing, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

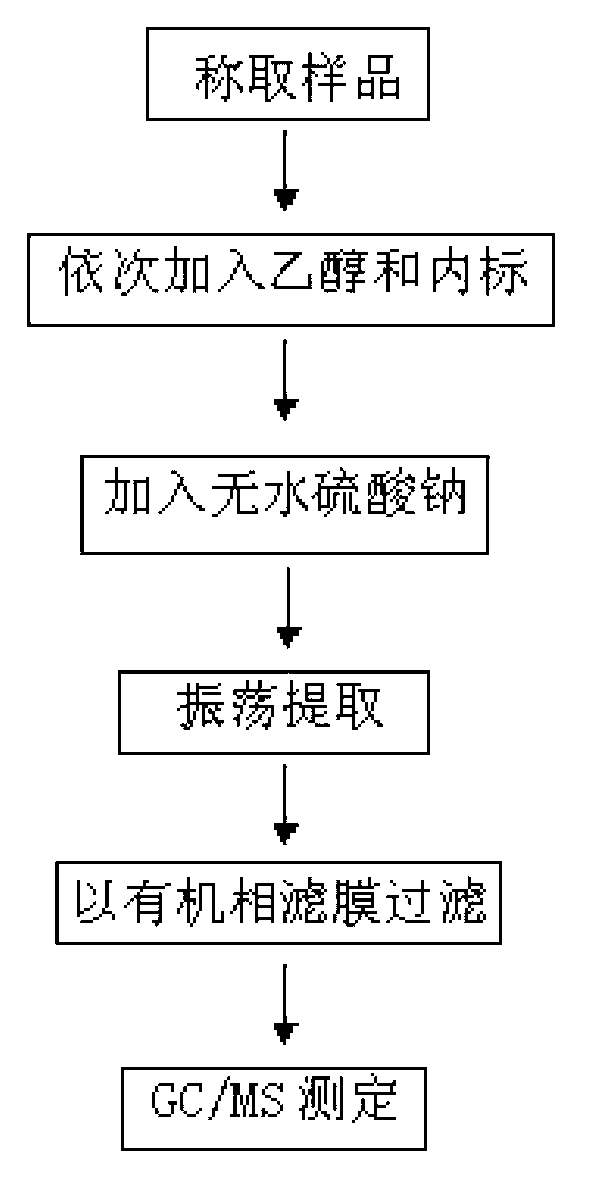

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of internal standard solution: take the internal standard phenylethyl propionate, use ethanol as the extractant, and prepare a 1mg / mL ethanol phenylethyl propionate solution;

[0044] (2) Standard solution preparation

[0045] Take by weighing 0.0250g methanol, sec-butanol, sesamol and musk xylene respectively, dissolve and settle to 250mL with absolute ethanol, and prepare the mixed mother liquor of methanol, sec-butanol, sesamol and musk xylene of 100 μg / mL, Accurately pipette 0.01mL, 0.02mL, 0.05mL, 0.1mL, 0.2mL, 0.5mL, 1mL of mixed mother liquor of methanol, sec-butanol, sesamol and musk xylene into a 10mL volumetric flask, and add 50μL of phenylethyl propionate ethanol solution (the concentration of phenylethyl propionate is 1mg / mL), and then dilute to volume with ethanol to prepare mixed standard working solutions of different concentrations of methanol, sec-butanol, sesamol and xylene musk, standard sequence: 0.1μg / mL, 0.2μg / mL, 0.5μg / mL, 1μg / mL...

Embodiment 2

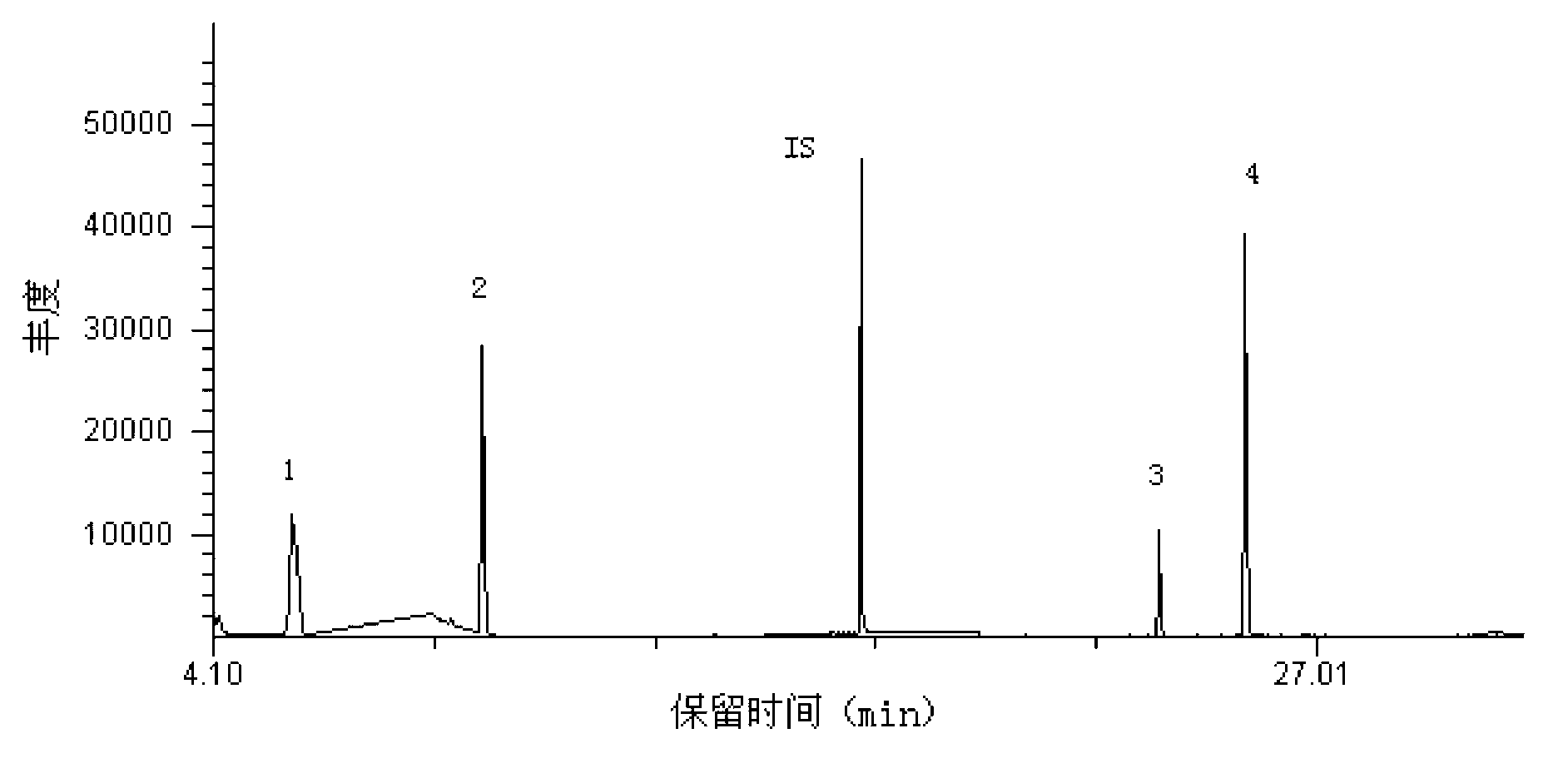

[0055] Accurately weigh 1g of tobacco feed liquid sample (accurate to 0.0001g), accurately add 10mL of absolute ethanol, and 50μL of ethanol solution of phenylethyl propionate (the concentration of phenylethyl propionate is 1mg / mL), and then add 3g Anhydrous sodium sulfate (baked in a muffle furnace at 520°C for 5 hours before use), shake gently for a few times, then shake on a shaker at a rate of 190rpm for 35min, let stand, filter with a 0.45μm organic phase filter membrane, and the filtrate is subjected to GC / MS analysis; Assay method is as described in Example 1, and the chromatogram is shown in Figure 4 The measured methanol content in the sample is 34.8mg / kg, the content of sec-butanol is 54.8mg / kg, and the content of xylene musk is 21.6mg / kg.

Embodiment 3

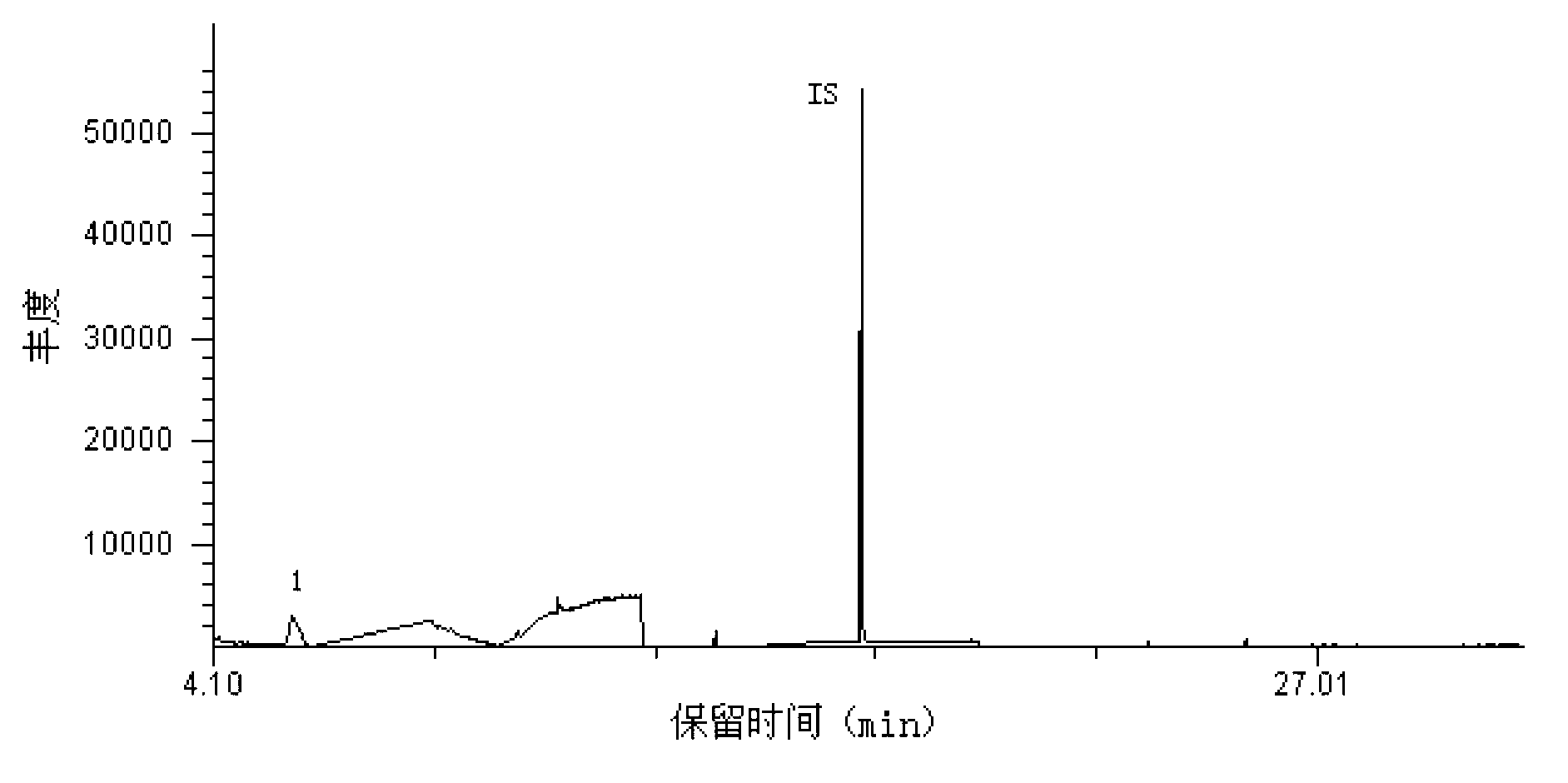

[0057] Accurately weigh 1g of tobacco feed liquid sample (accurate to 0.0001g), accurately add 10mL of absolute ethanol, and 50μL of ethanol solution of phenylethyl propionate (the concentration of phenylethyl propionate is 1mg / mL), and then add 2g Anhydrous sodium sulfate (baked in a muffle furnace at 500°C for 4.5h before use), shake gently for a few times, then shake at a speed of 180rpm for 30min on the shaker, let stand, filter with a 0.45μm organic phase filter membrane, and the filtrate is GC / MS analysis; Determination method is as described in embodiment 1, and chromatogram sees Figure 5 , The content of sesamol in the sample was measured to be 69.1mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com