Highly-dielectric battery diaphragm

A battery separator and high dielectric technology, which is applied in the field of membrane materials, can solve the problem that the ionic conductivity of the electrolyte is not improved, and achieve the effects of enhancing the retention rate, improving the ionic conductivity and improving the overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

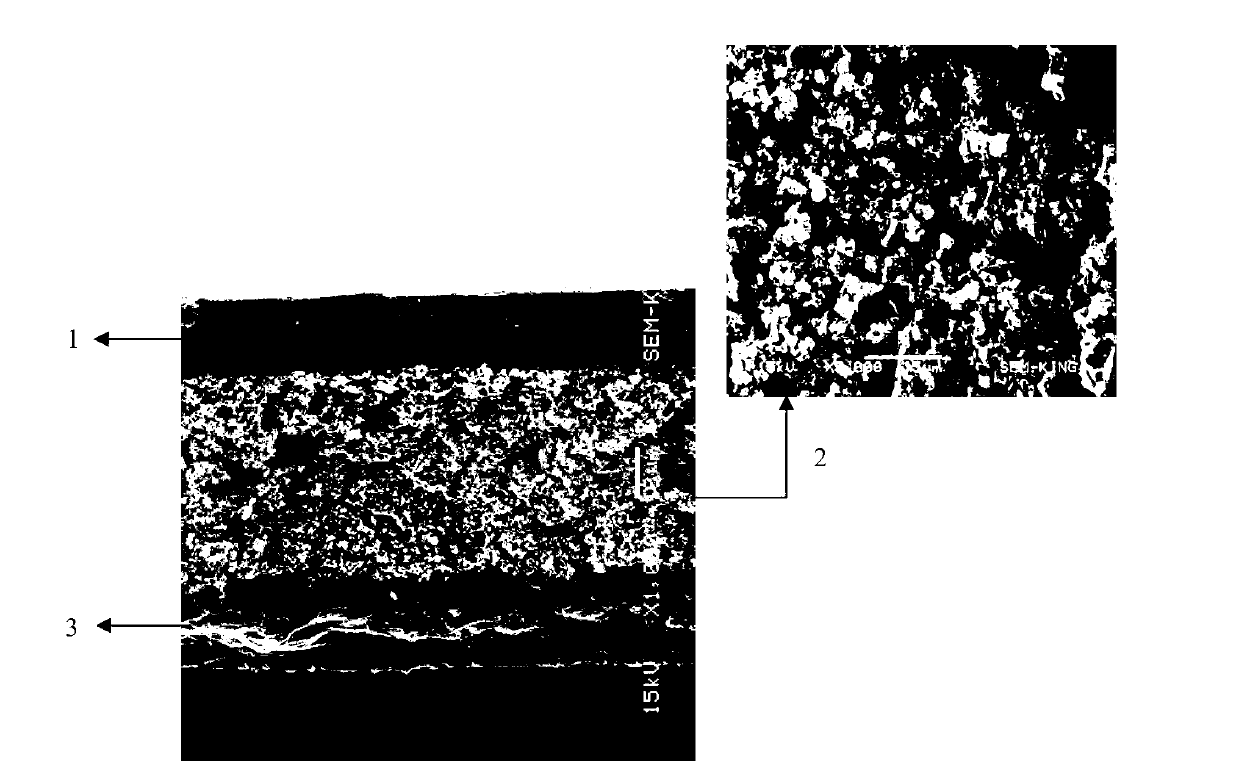

[0024] This embodiment describes that the first layer and the third layer of film are PP-PE porous composite membranes for conventional lithium batteries, and the second layer of film is BaTiO 3 Separator composed of particles for Li-LiMn 2 o 4 condition of the battery.

[0025] 1) Add 0.90gBaTiO 3 Dissolve in 5mL N-methylpyrrolidone, and oscillate ultrasonically for 30 minutes to disperse evenly;

[0026] 2) Evenly coat the dispersion on the PP-PE base film for conventional lithium batteries, with a coating thickness of 50 μm;

[0027] 3) Then cover another layer of PP-PE base film for conventional lithium batteries;

[0028] 4) Put it in a vacuum oven and bake at 80°C for 12 hours to obtain a sandwich composite film a.

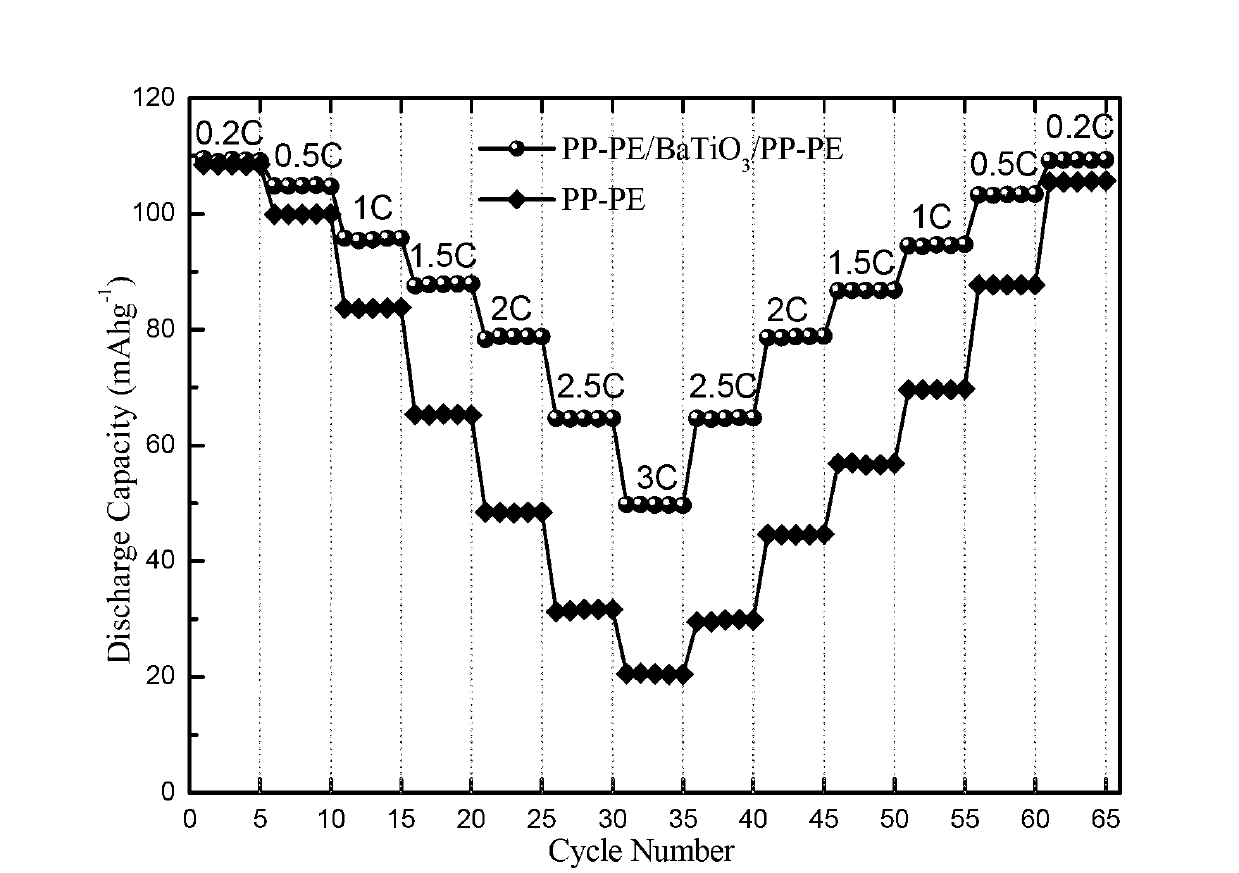

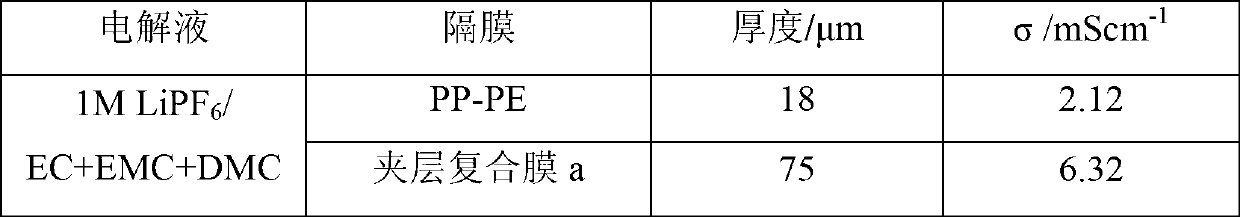

[0029] The above-mentioned interlayer composite film a and conventional lithium battery PP-PE film were assembled into a model battery system: conventional stainless steel electrode / diaphragm + electrolyte (1MLiPF 6 / EC+EMC+DMC) / conventional stainless ...

Embodiment 2

[0042] This example describes that the first layer of film is a PP-PE composite porous film for conventional lithium batteries, the second layer of film is a strontium titanate film, and the third layer of film is a polyvinylidene fluoride PVDF film (prepared by the following step 2 ), forming the separator, for graphite-LiCoO 2 The situation in lithium-ion batteries.

[0043] (1) Take 9.5g of strontium titanate, add 0.5g of polyvinylidene fluoride, dissolve it with 6mL of NMP, and coat it on a glass plate with a thickness of 50 μm, and dry it in vacuum at 80°C to form a film for use;

[0044] (2) Take 5g of polyvinylidene fluoride, dissolve it in 50g of NMP, and coat it on a glass sheet with a thickness of 10 μm, and dry it in vacuum at 80°C to form a film, that is, polyvinylidene fluoride PVDF film;

[0045] (3) The membrane obtained in step (1) is sandwiched between the conventional PP-PE composite porous membrane for lithium batteries and the polyvinylidene fluoride PVDF ...

Embodiment 3

[0057] This example describes the situation where the first layer of film is a common micron-sized nylon non-woven fabric, the second layer of film is copper calcium titanate particles, and the third layer of film is a polyvinyl alcohol film to form a separator for use in nickel-metal hydride batteries. :

[0058] (1) Take 5g of polyvinyl alcohol, dissolve the coating film with distilled water, heat and dry at 50°C for 5 hours to obtain a polyvinyl alcohol film; spread a layer of copper calcium titanate with a particle size of 2-2.5 μm evenly on it, and the spreading thickness is 10 μm; cover it with a layer of common micron-sized nylon non-woven fabric, and compact the obtained sandwich film with a roller press to obtain a sandwich composite film c.

[0059] The above-mentioned interlayer composite film c and common micron-sized nylon non-woven fabrics are used as battery separators respectively to form a model battery system: conventional stainless steel electrode / diaphragm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com