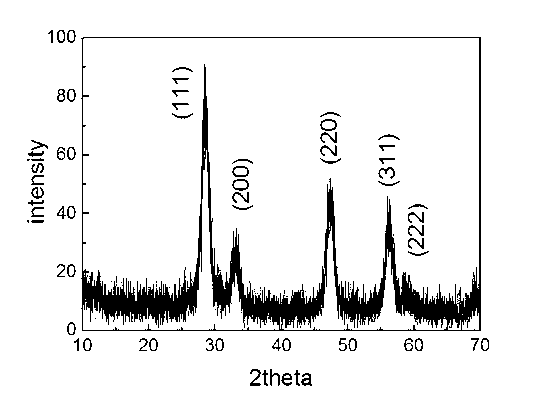

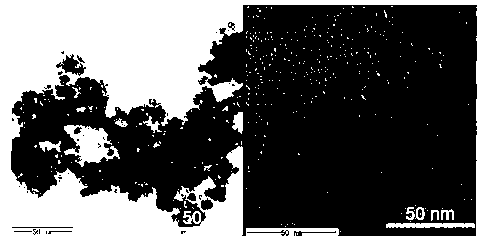

Industrial microwave rapid synthesis method of ultra-large specific surface area nano cerium dioxide

A technology of nano-cerium dioxide and specific surface area, which is applied in chemical instruments and methods, nanotechnology, rare earth metal compounds, etc., can solve the problems of poor safety, difficulty in industrial scale-up synthesis, and high requirements for instruments and equipment, and achieve the synthesis device Simple, low raw material purity requirements, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An industrial microwave rapid synthesis method of ultra-large specific surface area nano ceria, the preparation steps are as follows:

[0033] d. The cerium source can be selected from cerous nitrate (Ce(NO 3 ) 3 Industrial grade), ammonium cerium nitrate ((NH 4 ) 2 Ce(NO 3 ) 6 Industrial grade), cerous chloride (CeCl 3 Industrial grade), tetraethylenepentamine is the alkali source, and the solvent is water;

[0034] e. Add the cerium source and water into an ordinary plastic container, the volume ratio of the cerium source and water is 30 parts: 80 parts by volume, stir for 15 min, then add 130 parts of organic base to the above solution, and continue stirring for 30 min , the microwave power is 4000 W, the current is 1 A, and the reaction time is 50 min under the condition of blasting.

[0035] f. After the reaction is completed, take it out, separate the precipitate, wash it with water, wash away the surface lye and impurities, and dry it.

[0036]

Embodiment 2

[0038] An industrial microwave rapid synthesis method of ultra-large specific surface area nano ceria, the preparation steps are as follows:

[0039] The cerium ammonium nitrate was used as the cerium source, triethylenetetramine was used as the alkali source, and the solvent was water; the cerium source and 4.5 L of water were added to a plastic reaction vessel with a volume of 10 L, stirred for 15 min, and then 22.5 mL of triethylenetetramine was added. Add ethylenetetramine to the above solution, continue stirring for 30 min, adjust the power of the microwave oven to 4000 W, the current 1 A, and set the reaction time to 50 min. After the reaction is completed, take it out, separate the precipitate, wash it with water, wash away the surface lye and impurities, and dry it.

Embodiment 3

[0041] An industrial microwave rapid synthesis method of ultra-large specific surface area nano ceria, the preparation steps are as follows:

[0042] Use cerous chloride as the cerium source, triethylenetetramine as the alkali source, and water as the solvent; by volume, the volume ratio of the cerium source to water is 30 parts: 90 parts, stir for 15 min, and then add the organic base triethylenetetramine Add 150 parts of amine to the above solution, in a plastic reaction container, stir for 15 min, then add 22.5 mL triethylenetetramine to the above solution, continue stirring for 30 min, adjust the power of the microwave oven to 4000 W, the current 1 A, and set the reaction time to 50 min. After the reaction is completed, take it out, separate the precipitate, wash it with water, wash away the surface lye and impurities, and dry it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com