Device and method for developing carbon source in primary sludge to strengthen denitrification of municipal sewage

A technology for primary sedimentation of sludge and urban sewage, applied in water/sludge/sewage treatment, chemical instruments and methods, water pollutants, etc., can solve problems such as slowing down the fermentation reaction rate, and achieve product inhibition and controllability. The effect of strengthening and strengthening the denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

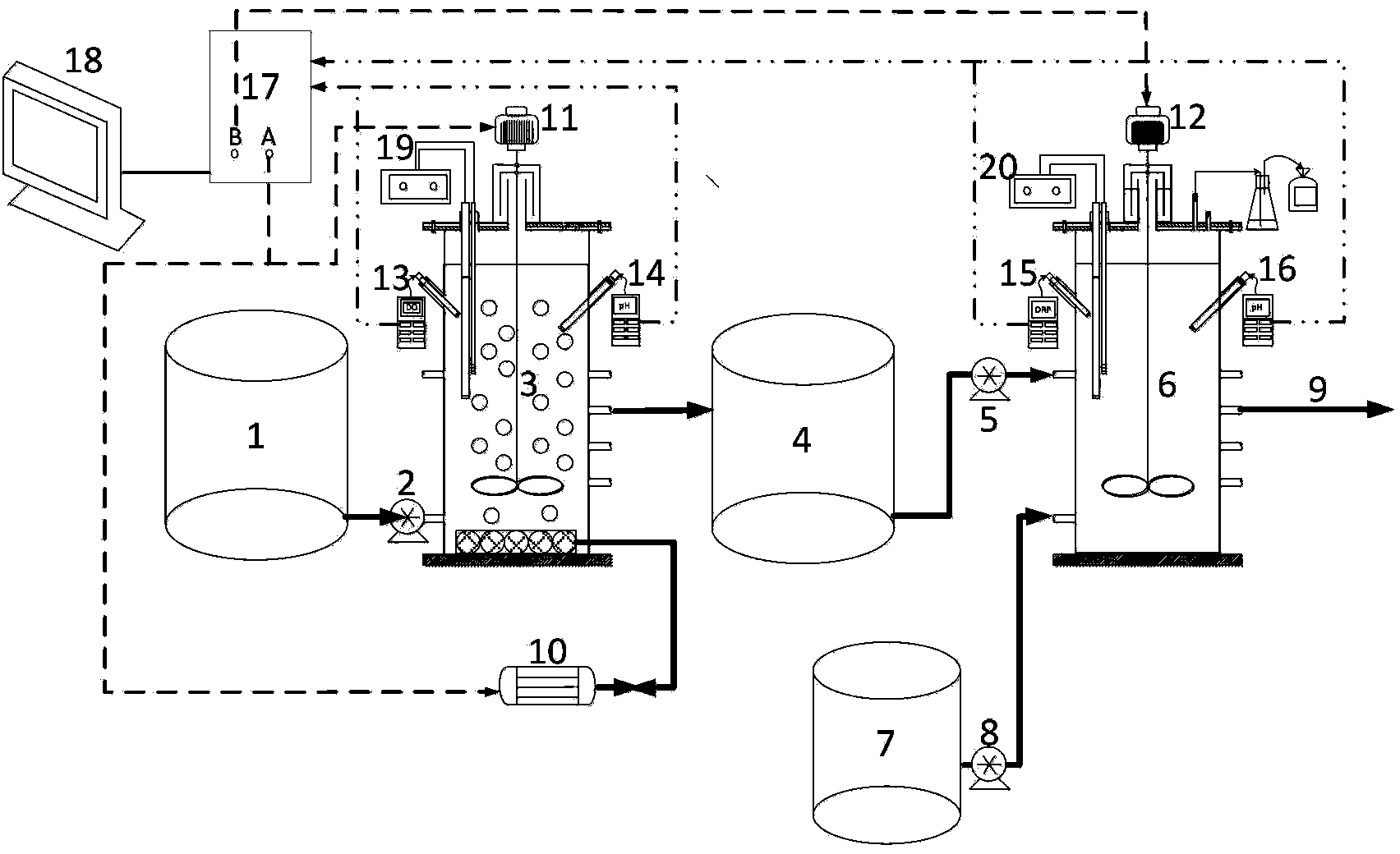

[0035] Sequencing batch nitration reactor SBR ND 3 To treat domestic sewage with low C / N ratio, each cycle goes through 5 processes of water intake, anoxic stirring, aeration, sedimentation and drainage.

[0036] ⅠWater intake Set the water intake of the water intake pump 2 to 500ml / min, and feed water for 10 minutes. After the system is started, the sewage in the raw water tank 1 enters the sequencing batch nitrification reactor SBR through the inlet pump 2 ND 3. Turn on the first agitator 11 while entering the water.

[0037] Ⅱ Anoxic stirring After the water intake is completed, it enters the anoxic stirring period, and the denitrification time is set to 30 minutes.

[0038] Ⅲ Aeration Turn on the air compressor 10 to supply the air to the sequencing batch nitrification reactor SBR ND Provide oxygen, the aeration rate is constant at 40L / hour, and make the sewage and activated sludge fully contact. According to online monitoring of DO and pH, when ①dpH / dt≥0 and t≥2h or ②...

Embodiment 2

[0048] Sequencing batch nitration reactor SBR ND 3 To treat domestic sewage with low C / N ratio, each cycle goes through 5 processes of water intake, anoxic stirring, aeration, sedimentation and drainage.

[0049] ⅠWater intake Set the water intake of the intake pump 2 to 1L / min, for 5 minutes. After the system is started, the sewage in the raw water tank 1 enters the sequencing batch nitrification reactor SBR through the inlet pump 2 ND 3. Turn on the first agitator 11 while entering the water.

[0050] Ⅱ Anoxic stirring After the water intake is completed, it enters the anoxic stirring period. According to the treated water quality, set the denitrification time to 60 minutes.

[0051] Ⅲ Aeration Turn on the air compressor 10 to supply the air to the sequencing batch nitrification reactor SBR ND Provide oxygen to convert the ammonia nitrogen in the influent into the oxidized nitrogen NO x - ; According to online monitoring of DO and pH, when ①dpH / dt≥0 and t≥2h or ②dDO / dt>...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com