Method for preparing polystyrene/sodium monofluorophosphate microcapsule corrosion inhibitor

A technology of sodium monofluorophosphate and polystyrene, which is applied in the field of concrete steel rust inhibitor, can solve the problems of slow penetration speed, lower concentration, and lower anti-rust effect, and achieve the effect of avoiding impact and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

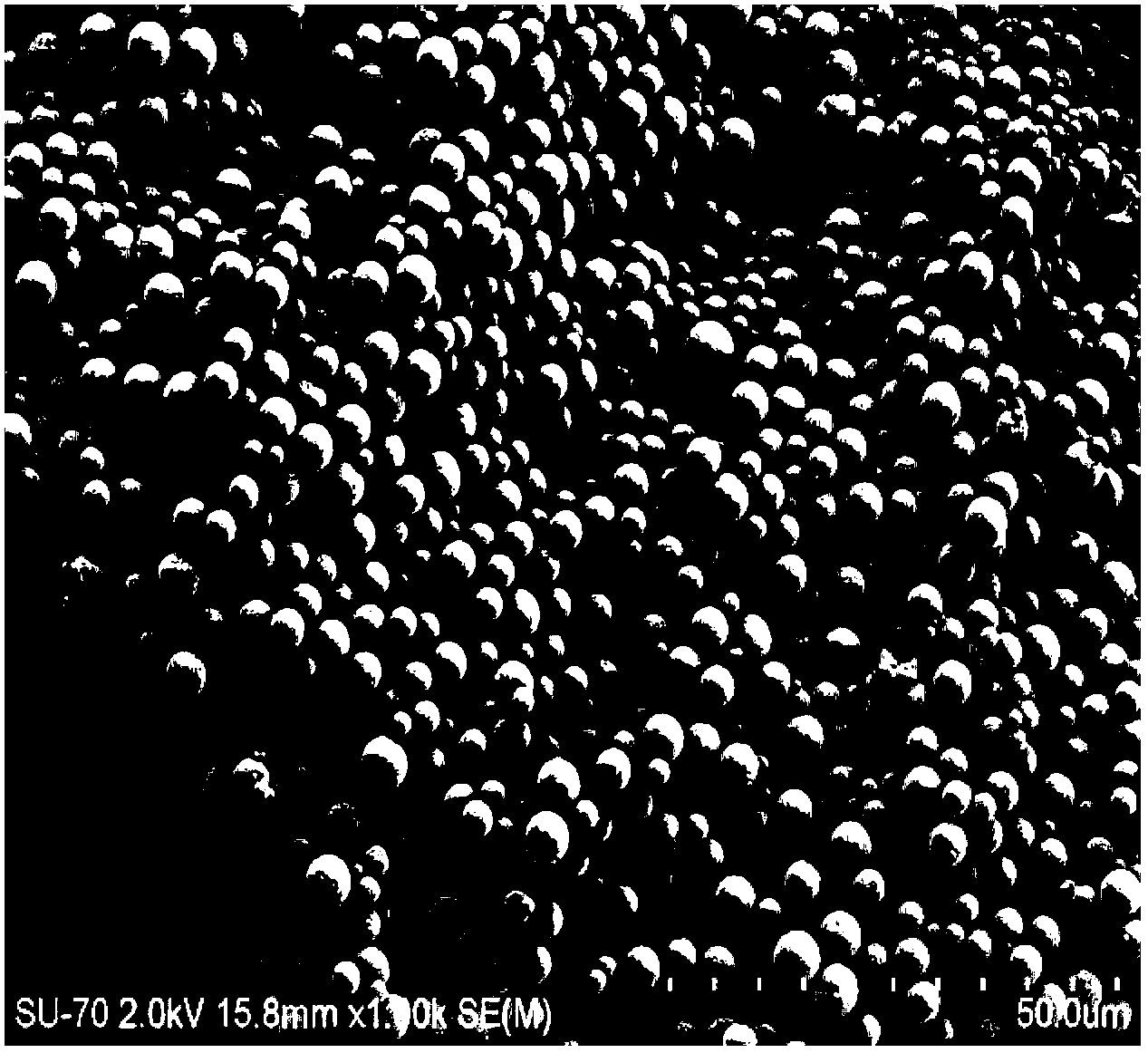

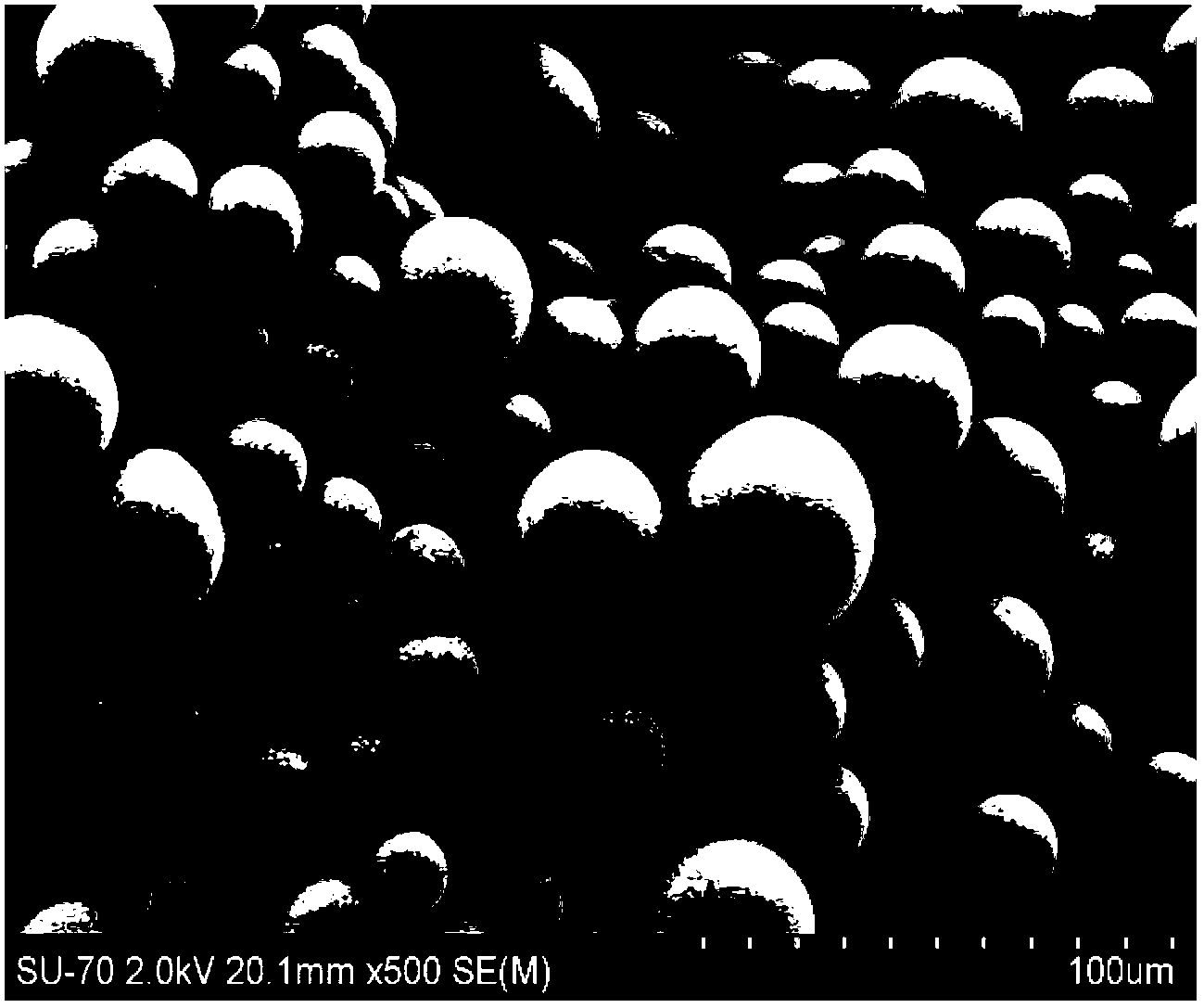

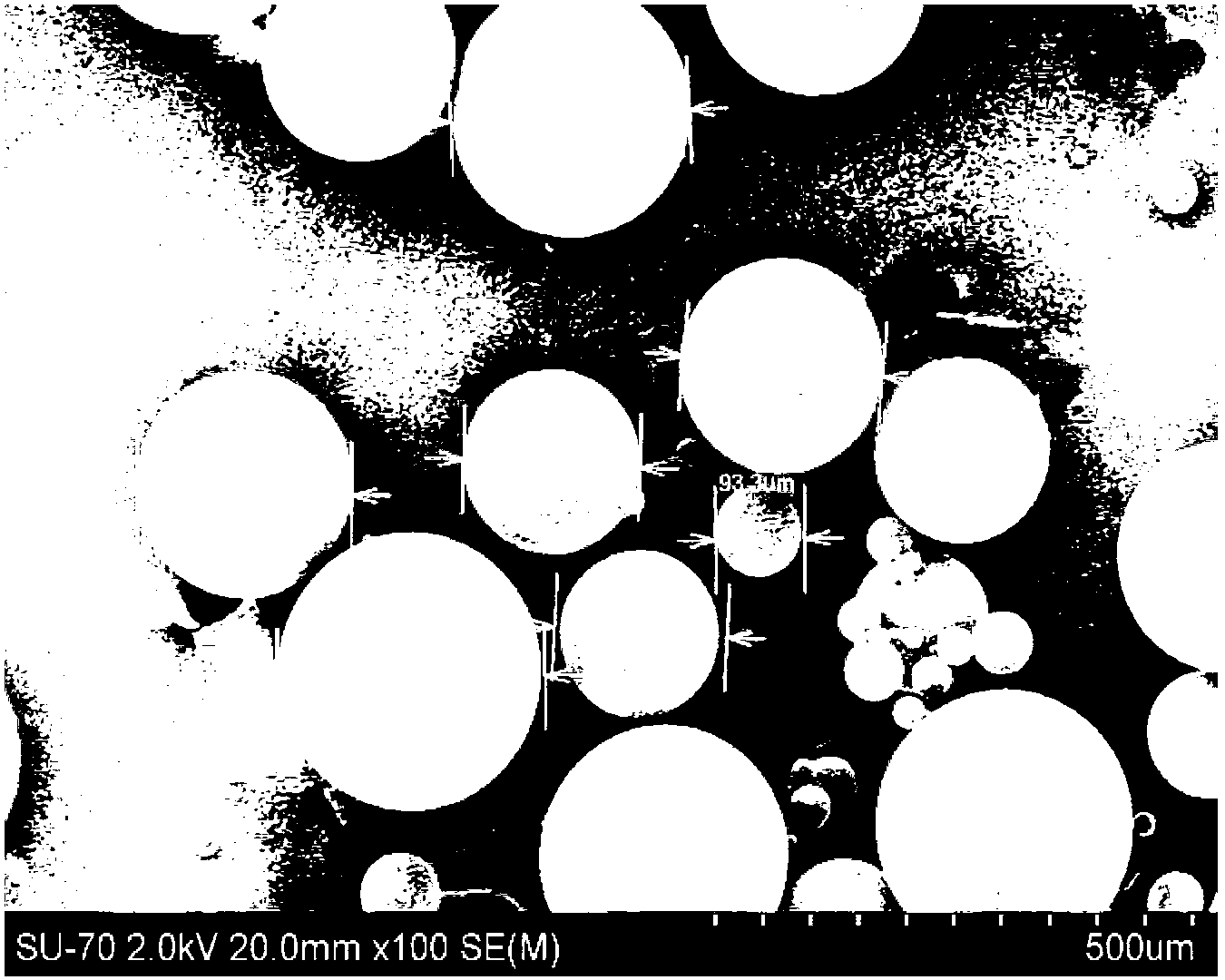

Image

Examples

Embodiment 1

[0037] 1. Raw materials:

[0038] Rust inhibitor: sodium monofluorophosphate (toothpaste grade, Hubei Xingfa Chemical Group Co., Ltd.): 80g;

[0039] Emulsifier: Tween 80 (chemically pure, Guangdong Yueqiao Reagent Plastic Co., Ltd.): 0.2g;

[0040] Protective colloid: polyethylene glycol (chemically pure, Shanghai Yili Biotechnology Co., Ltd.): 2 g,

[0041] Microcapsule shell material: polystyrene resin (5250, Taiwan Taihua): 20g;

[0042] PS solvent: dichloromethane (chemically pure, Guangdong Guanghua Chemical Factory Co., Ltd.), 180 g;

[0043] distilled water.

[0044] 2. Equipment:

[0045] Constant temperature water bath, stirrer, three-neck flask

[0046] Preparation Process:

[0047] 1) Make 80 g of sodium monofluorophosphate into a saturated aqueous solution of sodium monofluorophosphate, then add 0.2 g of Tween 80, stir and dissolve, and make an aqueous phase.

[0048] 2) Dissolving 20g of polystyrene in 180g of methylene chloride to make an oil phase, the t...

Embodiment 2

[0054]1. Raw materials:

[0055] Rust inhibitor: sodium monofluorophosphate (toothpaste grade, Hubei Xingfa Chemical Group Co., Ltd.): 80g;

[0056] Emulsifier: sodium lauryl sulfate: (chemically pure,) 0.1g;

[0057] Protective colloid: polyethylene glycol: (chemically pure, Shanghai Yili Biotechnology Co., Ltd.): 2 g;

[0058] Microcapsule shell material: polystyrene resin (5250, Taiwan Taihua): 30 g;

[0059] PS solvent: chloroform (chemically pure, Guangdong Guanghua Chemical Co., Ltd.), 180 g;

[0060] distilled water.

[0061] 2. Equipment:

[0062] Constant temperature water bath, stirrer, three-neck flask

[0063] Preparation Process:

[0064] 1) Make 80g of sodium monofluorophosphate into a saturated aqueous solution of sodium monofluorophosphate, add 0.5g of Tween 80, stir and dissolve, and make an aqueous phase;

[0065] 2) Dissolving 30g of polystyrene in 180g of chloroform to make an oil phase, the temperature of the water bath is 60°C.

[0066] 3) Mix the...

Embodiment 3

[0071] 1. Raw materials:

[0072] Rust inhibitor: sodium monofluorophosphate (toothpaste grade, Hubei Xingfa Chemical Group Co., Ltd.): 80g;

[0073] Emulsifier: Tween 80 (chemically pure, Guangdong Yueqiao Reagent Plastic Co., Ltd.): 1g;

[0074] Protective colloid: polyvinyl alcohol (chemically pure, Shanghai Yili Biotechnology Co., Ltd.): 6 g,

[0075] Microcapsule shell material: polystyrene resin (5250, Taiwan Taihua): 40g;

[0076] PS solvent: dichloromethane (chemically pure, Guangdong Guanghua Chemical Factory Co., Ltd.), 180 g;

[0077] distilled water.

[0078] 2. Equipment:

[0079] Constant temperature water bath, stirrer, three-neck flask

[0080] Preparation Process:

[0081] 1) Make 80 g of sodium monofluorophosphate into a saturated aqueous solution of sodium monofluorophosphate, add 1 g of Tween 80, stir and dissolve, and make an aqueous phase.

[0082] 2) Dissolving 40g of polystyrene in 180g of dichloromethane to make an oil phase, the temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com