Novel process for high-effective extraction of carotenoid in Blakeslea trispora

A technology of carotene and boulardii, which is applied in the purification/separation of hydrocarbons, hydrocarbons, organic chemistry, etc. It can solve the problems of complex carotenoid crystal process, difficulty in guaranteeing crystal purity and quality, and unfavorable efficiency for industrial production. , to achieve the effect of being beneficial to industrial production, less organic solvent, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] ①Take 40g of dry lycopene mycelium, in which the total carotenoid content is 5.1%. The lycopene and β-carotene account for 80% and 20% respectively by HPLC, and 200ml of ethyl acetate is added to the mycelium. , grind with a ball mill for 30min at 25°C, extract the carotenoids in the mycelium while breaking the cell wall, filter, and collect the filtrate;

[0053] 2. Add 200 ml of ethyl acetate to the filter residue of step 1, grind at 25°C for 30min with a ball mill, filter, and collect the filtrate; add 200ml of ethyl acetate to the filter residue, grind at 25°C for 30min with a ball mill, filter, and collect the filtrate;

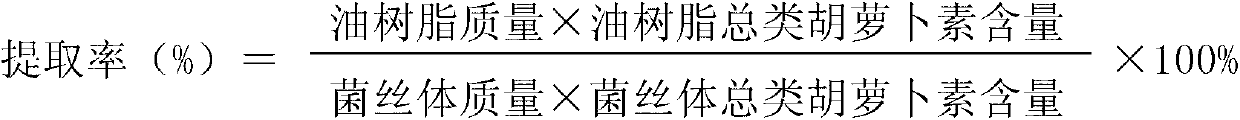

[0054] 3. The filtrate obtained in the combined steps 1. and 2. is concentrated under vacuum to obtain 39.4 g of oleoresin with a total carotenoid content of 5.12% at 50°C; the extraction rate is 98.9%;

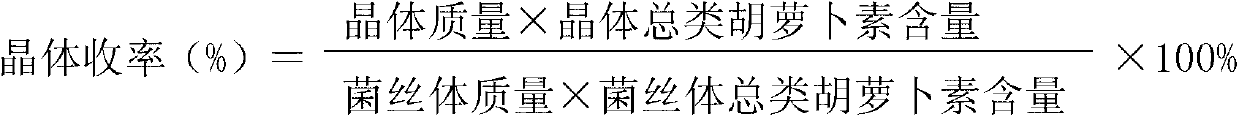

[0055] 4. Add 400 ml of ethanol to the oleoresin in step 3, stir and wash at 50°C for 30min, filter to remove the solution, and dry at 40°C for ...

Embodiment 2

[0058] ①Take 40g dry lycopene mycelium, in which the total carotenoid content is 5.3%, and lycopene and β-carotene account for 79% and 21% respectively by HPLC detection, add 400ml dichloromethane to the mycelium , Homogenize under high pressure for 30min at 25℃, extract the carotenoids in the mycelium while breaking the cell wall, filter, and collect the filtrate;

[0059] ②Add 200ml of dichloromethane to the filter residue of step ①, homogenize under high pressure for 30min at room temperature, filter,

[0060] Collect the filtrate; add 100 ml of dichloromethane to the filter residue, homogenize under high pressure for 30 min at 25°C, filter, and collect the filtrate;

[0061] 3. the filtrate obtained in the combined steps 1. and 2. is concentrated in a vacuum at 50° C. to obtain 28.6 g of oleoresin with a total carotenoid content of 6.79%, and the extraction rate is 91.6%;

[0062] 4. Add 400 ml of ethanol to the oleoresin in step 3, stir and wash at 50°C for 30min, filter...

Embodiment 3

[0065] ①Take 40g of dry β-carotene mycelium, in which the total carotenoid content is 6.5%. The β-carotene and lycopene account for 98% and 2% respectively by HPLC, and 400ml of n-hexane is added to the mycelium. , sheared at 25°C for 30min, the carotenoids in the mycelium were extracted while the cell wall was broken, filtered, and the filtrate was collected;

[0066] ②Add 120ml of n-hexane to the filter residue in step ①, shear at 25°C for 10min, filter, and collect the filtrate; add 40ml of n-hexane to the filter residue, shear at 25°C for 10min, filter, and collect the filtrate;

[0067] 3. the filtrate obtained in the combined steps 1. and 2. is concentrated in a vacuum at 50°C to obtain 44.9 g of oleoresin with a total carotenoid content of 5.67%, and the extraction rate is 97.9%;

[0068] 4. Add 300 ml of ethanol to the oleoresin in step 3, stir and wash at 50° C. for 10 minutes, filter to remove the solution, and dry at 40° C. for 2 hours to obtain carotenoid crystals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com