Method for oxidizing thiophene sulfides

A technology for sulfide and catalytic oxidation, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve good overall selectivity, mild reaction conditions, and simple production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

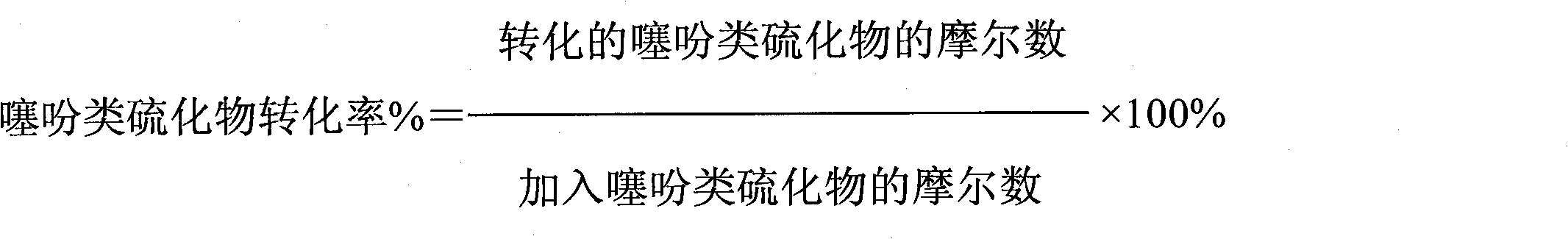

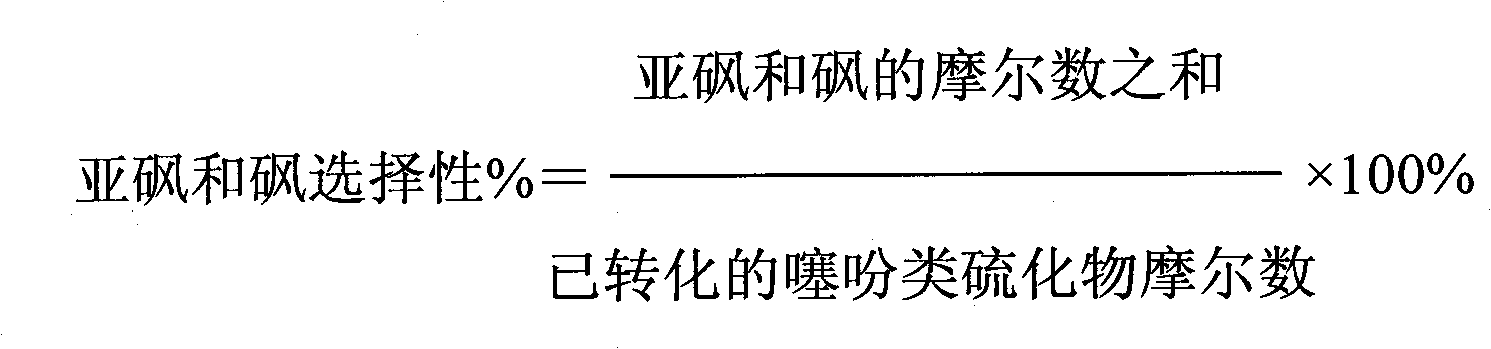

[0042] Thiophene, hydrogen peroxide, solvent and catalyst (TS-1 and phosphotungstic heteropolyacid H 3 PW 12 o 40 The mass ratio of thiophene and hydrogen peroxide is 1: 1) according to the molar ratio of thiophene and hydrogen peroxide is 1: 2, the mass ratio of solvent methanol and catalyst is 20: 1, the mass ratio of thiophene and catalyst is 20: 1, at a temperature of 50 ° C and a pressure The reaction was carried out at 1.5MPa. The results of the 2-hour reaction were as follows: the conversion rate of thiophene was 44%; the total selectivity of sulfoxide and sulfone was 92%.

Embodiment 2

[0044] 2-chlorothiophene, hydrogen peroxide, solvent and catalyst (TS-1 and molybdenum tungsten heteropoly blue H 5 MoW 12 o 40 The mass ratio is 0.1: 1) according to the mol ratio of sulfide and hydrogen peroxide is 1: 4, the mass ratio of solvent methanol and catalyst is 120: 1, the mass ratio of sulfide and catalyst is 40: 1, at temperature The reaction was carried out at 50° C. under a pressure of 1.0 MPa. The result of reaction for 2 hours is as follows: the conversion rate of thiophene sulfide is 62%; the total selectivity of sulfoxide and sulfone is 93%.

Embodiment 3

[0046] With 2-methylthiophene, hydrogen peroxide, solvent acetone and catalyst (TS-1 and homovanadic acid H 4 V 2 o 7 The mass ratio of thiophene and hydrogen peroxide is 50: 1) according to the molar ratio of thiophene and hydrogen peroxide is 1: 5, the mass ratio of solvent acetone and catalyst is 200: 1, the mass ratio of thiophene and catalyst is 80: 1, at a temperature of 60 ° C The reaction was carried out at a pressure of 1.0 MPa. The result of reaction for 2 hours is as follows: the conversion rate of thiophene sulfide is 67%; the total selectivity of sulfoxide and sulfone is 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com