Dry powder adhesive for paper products and preparation method thereof

A technology for adhesives and paper products, applied in the direction of adhesives, adhesive types, graft polymer adhesives, etc., to achieve the effect of reducing weight and volume, extending shelf life, and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

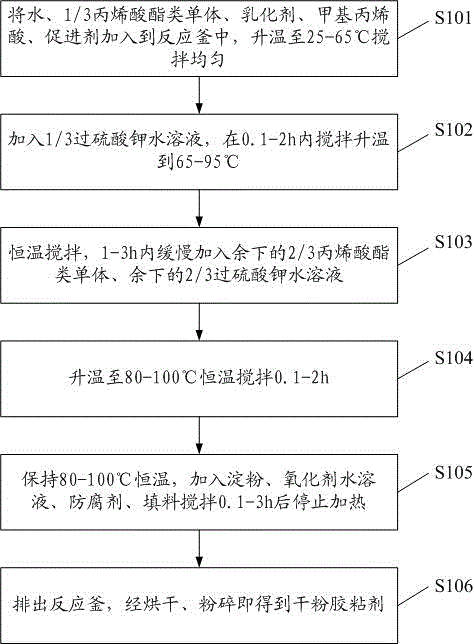

Method used

Image

Examples

reference example 1

[0144] Add 40Kg water, 25Kg acrylate, 2Kg sodium lauryl sulfate, 4Kg methacrylic acid, 0.5Kg zinc acetate into a 500L reactor, heat up to 35°C and stir evenly; add 0.2Kg K 2 S 2 o 8 The prepared aqueous solution was stirred and heated to 65°C within 0.1h; stirred at constant temperature, and 30Kg acrylate, 0.6Kg K were slowly added within 1.5h 2 S 2 o 8 The prepared aqueous solution was heated up to 80°C and stirred at a constant temperature for 0.5h to prepare a certain brand of hardcover box glue on the market.

[0145] How to use: use it directly, evenly apply it on the face paper for bonding.

Embodiment 1

[0147] Add 45Kg deionized water, 15Kg acrylate, 3Kg sodium lauryl sulfate, 6Kg methacrylic acid, 0.3Kg zinc acetate into a 500L reactor, heat up to 45°C and stir evenly; add 0.3Kg K 2 S 2 o 8 The prepared aqueous solution was stirred and heated to 80°C within 0.5 hours; stirred at constant temperature, 30Kg acrylate, 0.6Kg K 2 S 2 o 8 Prepared aqueous solution; heat up to 90°C and stir for 0.5h; maintain a constant temperature of 90°C, add 150Kg soybean starch, 1.8Kg ammonium persulfate aqueous solution, 0.03Kg sodium diacetate, 48Kg calcium carbonate, stir for 1h, stop heating, discharge the reaction kettle, put Put it into an oven, bake at 125 degrees Celsius for 3 hours, then cool to room temperature and pulverize with a mill to obtain a dry powder adhesive.

[0148] Wherein, the acrylate selected in embodiment 1 is methyl acrylate.

[0149] How to use: Stir the dry powder adhesive with water 1:5 to make a paste and apply it evenly on the surface paper for bonding.

Embodiment 2

[0151] Add 40Kg of deionized water, 17Kg of acrylate, 3Kg of sodium lauryl sulfate, 6Kg of methacrylic acid, and 0.3Kg of zinc acetate into a 500L reactor, raise the temperature to 45°C and stir evenly; add 0.3Kg of K 2 S 2 o 8 The prepared aqueous solution was stirred and heated to 80°C within 0.5 hours; stirred at constant temperature, 34Kg acrylate, 0.6Kg K 2 S 2 o 8 Prepared aqueous solution; heat up to 90°C and stir for 0.5h; maintain a constant temperature of 90°C, add 140Kg cornstarch, 1.8Kg ammonium persulfate aqueous solution, 0.03Kg sodium diacetate, 59Kg kaolin, stir for 1h, stop heating, discharge the reaction kettle, put Oven, bake at 120 degrees Celsius for 2.5 hours, then cool to room temperature and pulverize with a mill to obtain a dry powder adhesive.

[0152] Wherein, the acrylate selected in embodiment 2 is ethyl acrylate.

[0153] How to use: Stir the dry powder adhesive with water at a ratio of 1:6 to form a paste, and apply it evenly on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com