Precision-type mischmetal polishing powder and preparation method thereof

A technology of mixing rare earth and polishing powder, which is applied in the direction of chemical instruments and methods, polishing compositions containing abrasives, and other chemical processes, and can solve the problems of uneven original grain size, quality fluctuation, and many small-sized particles of polishing powder. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of precision type mixed rare earth polishing powder of the present invention, it comprises the steps:

[0035] (1) Ball milling: mix rare earth carbonate with water, and then ball mill to obtain rare earth carbonate slurry;

[0036] (2) Fluorination: heat the rare earth carbonate slurry, add 40% hydrofluoric acid solution dropwise under stirring conditions, add a homogenization aid after the dropwise addition and keep it warm for 1-3 hours to obtain rare earth fluorocarbonate;

[0037] (3) Roasting: Roasting the rare earth fluorocarbonate to obtain rare earth fluoride oxide;

[0038] (4) Pulverization: pulverize rare earth oxyfluoride to obtain mixed rare earth polishing powder.

[0039] In the present invention, the rare earth carbonate is selected from one or more of cerium carbonate, lanthanum cerium carbonate or lanthanum cerium carbonate.

[0040] In the present invention, the rare earth carbonate slurry contains 50%-70% by weight of rare e...

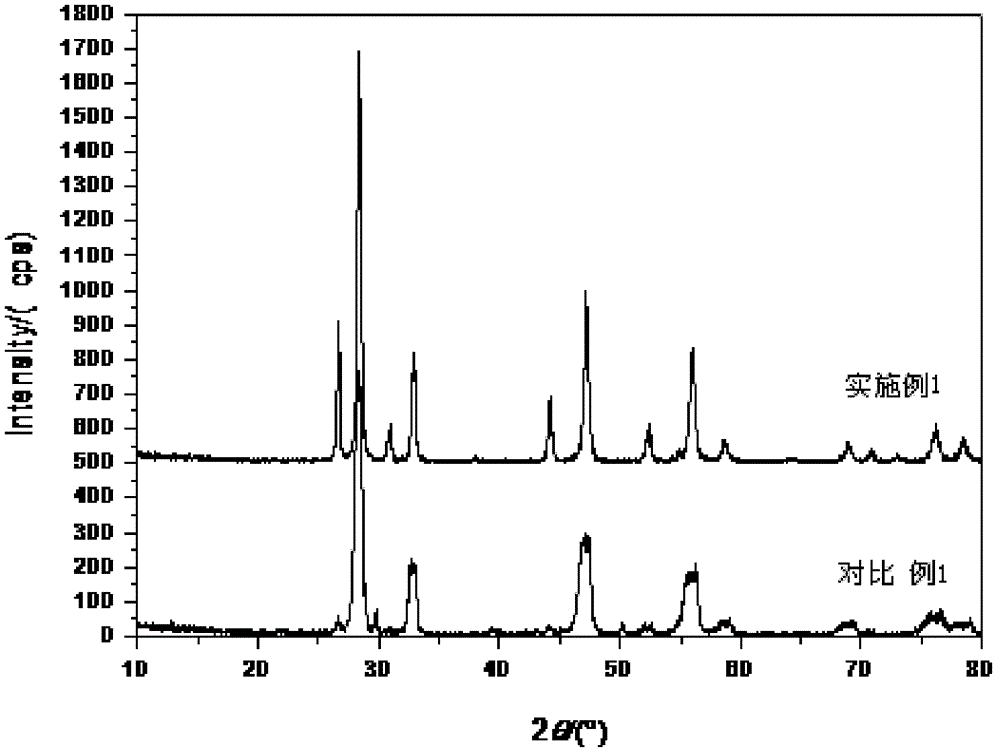

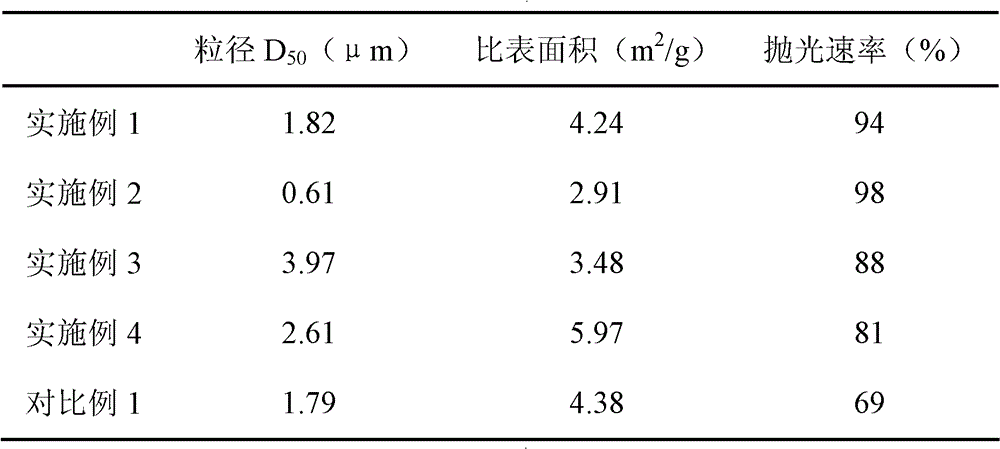

Embodiment 1

[0048] (1) Ball milling: 400kg of lanthanum cerium carbonate, 100kg of cerium carbonate and 330kg of water are mixed to prepare a lanthanum cerium carbonate slurry with a solid content of 60wt%. After ball milling for 2h, after filtering out the grinding beads, the lanthanum cerium carbonate slurry is obtained;

[0049] (2) Fluorination: heat the lanthanum cerium carbonate slurry to 50°C, add 30 kg of hydrofluoric acid dropwise according to 60 kg of acid / ton of rare earth carbonate, add 10 kg of ammonium sulfate after the dropwise addition, and keep warm for 1 hour to obtain lanthanum cerium fluoride carbonate slurry ;

[0050] (3) Roasting: Roasting the lanthanum cerium carbonate slurry at 980° C. for 4 hours to obtain lanthanum cerium oxyfluoride;

[0051] (4) Pulverization: the airflow pulverization of the gained lanthanum oxyfluoride cerium in (3) promptly obtains the rare earth polishing powder of the present invention, and the laser particle size analyzer test result is:...

Embodiment 2

[0053] (1) Ball milling: 500kg of lanthanum cerium carbonate is mixed with 500kg of water to prepare a lanthanum cerium carbonate slurry with a solid content of 50wt%, after ball milling for 2h, after filtering out the grinding beads, the lanthanum cerium carbonate slurry is obtained;

[0054] (2) Fluorination: Stir the lanthanum cerium carbonate slurry evenly, heat it to 30°C, add 20kg of hydrofluoric acid dropwise according to 40kg of acid / ton of rare earth carbonate, after the dropwise addition, add 30kg of ammonium phosphate, and keep warm for 2 hours to obtain fluorine Lanthanum cerium carbonate slurry;

[0055] (3) Roasting: Roasting the rare earth fluorocarbonate slurry at 950°C for 8 hours to obtain cerium lanthanum oxyfluoride;

[0056] (4) pulverization: the gained lanthanum cerium oxyfluoride of (3) is carried out jet pulverization, namely obtains the rare earth polishing powder of the present invention, and the laser particle size analyzer test result is: D 50 =0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com