Imidazole-type hybrid anion exchange membrane and preparation method thereof

An anion-exchange membrane, hybrid technology, applied in the field of imidazole-type hybrid anion-exchange membrane and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

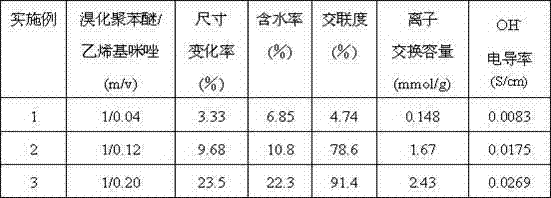

Embodiment 1-3

[0021] Firstly, 10 parts by weight of brominated polyphenylene ether are dissolved in 37 parts by weight of N-methylpyrrolidone (NMP); The mass-to-volume ratio is 1:0.04~0.20; then add the ultraviolet light reaction catalyst benzoin methyl ether, the amount of benzoin methyl ether added is 1% of the mass of brominated polyphenylene ether, and stir evenly to obtain the casting liquid; the prepared casting After the membrane solution is allowed to stand for defoaming, it is cast into a membrane; 50 o Dry at C for 15 hours; place under a UV lamp with a wavelength of 365 nm to react for 15 hours to obtain an imidazole-type hybrid anion exchange membrane. Soak the anion-exchange membrane in NaCl (1 mol / L) solution for chlorine type conversion, then wash it with a large amount of deionized water and store it.

[0022] These several examples are to investigate the influence of different vinylimidazole contents on the prepared imidazole type hybrid anion exchange membrane.

[0023] ...

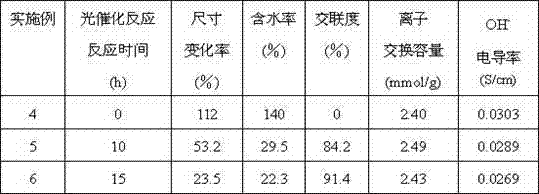

Embodiment 4-6

[0026] Firstly, 10 parts by weight of brominated polyphenylene ether are dissolved in 37 parts by weight of N-methylpyrrolidone (NMP); The mass-to-volume ratio of the product is 1:0.20; then add the ultraviolet light reaction catalyst benzoin methyl ether, the addition of benzoin methyl ether is 1% of the mass of brominated polyphenylene ether, and stir to obtain the casting solution; the prepared casting solution After static defoaming, cast into film; 50 o Dry at C for 15 hours; place under a UV lamp with a wavelength of 365 nm to react for 0 to 15 hours to obtain an imidazole-type hybrid anion exchange membrane. Soak the anion-exchange membrane in NaCl (1 mol / L) solution for chlorine type conversion, then wash it with a large amount of deionized water and store it.

[0027] These examples are to investigate the influence of different ultraviolet photocatalytic reaction times on the prepared imidazole type hybrid anion exchange membrane.

[0028]

[0029] It can be seen...

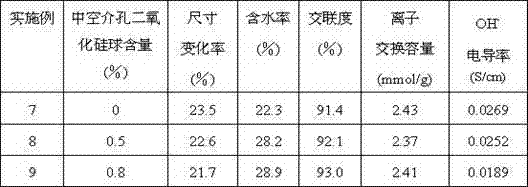

Embodiment 7-9

[0031] First, 0-0.08 parts by weight of hollow mesoporous silica spheres (hollow core size is about 200 nm, wall thickness is about 30 nm, and mesopore diameter is about 1.95 nm) are dispersed in 37 parts by weight of N-methylpyrrolidone (NMP); 10 parts by weight of brominated polyphenylene ether are dissolved in 37 parts by weight of N-methylpyrrolidone (NMP); then vinylimidazole is added to stir and react for 1h, the quality of brominated polyphenylene ether is the same as that added The mass-to-volume ratio of vinylimidazole is 1:0.20; then add the ultraviolet light reaction catalyst benzoin methyl ether, the addition of benzoin methyl ether is 1% of the mass of brominated polyphenylene ether, and stir to obtain the casting solution; the prepared After standing for defoaming, the casting solution was cast into a film; 50 o Dry at C for 15 hours; place under a UV lamp with a wavelength of 365 nm to react for 15 hours to obtain an imidazole-type hybrid anion exchange membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com