Magnetron sputtering apparatus and method

一种磁控溅射装置、磁控溅射的技术,应用在溅射镀覆、离子注入镀覆、涂层等方向,能够解决难高速成膜、成膜效率降低、反冲Ar能量大等问题,达到确保面内均匀性、提高成膜效率、保证成膜速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

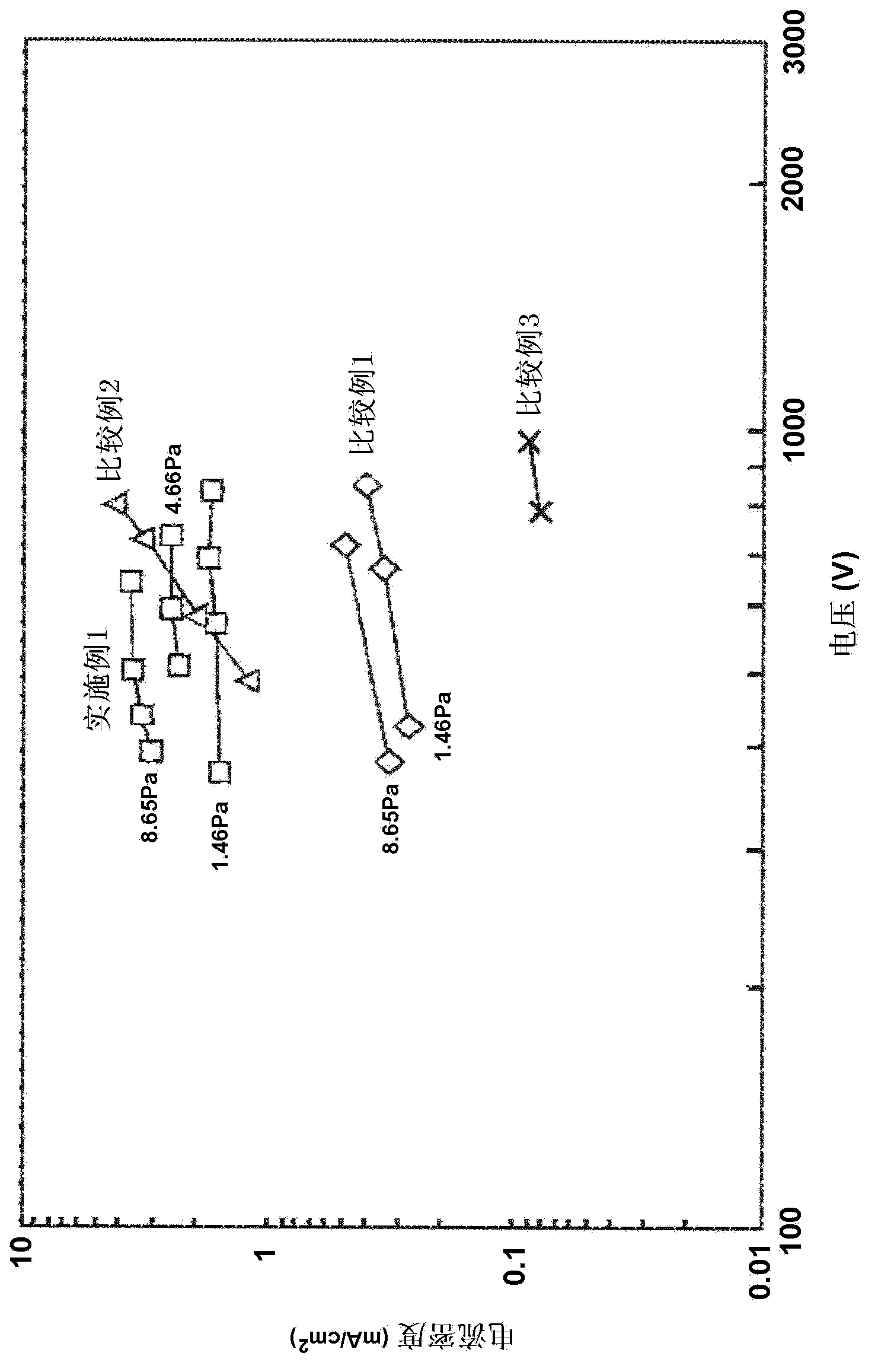

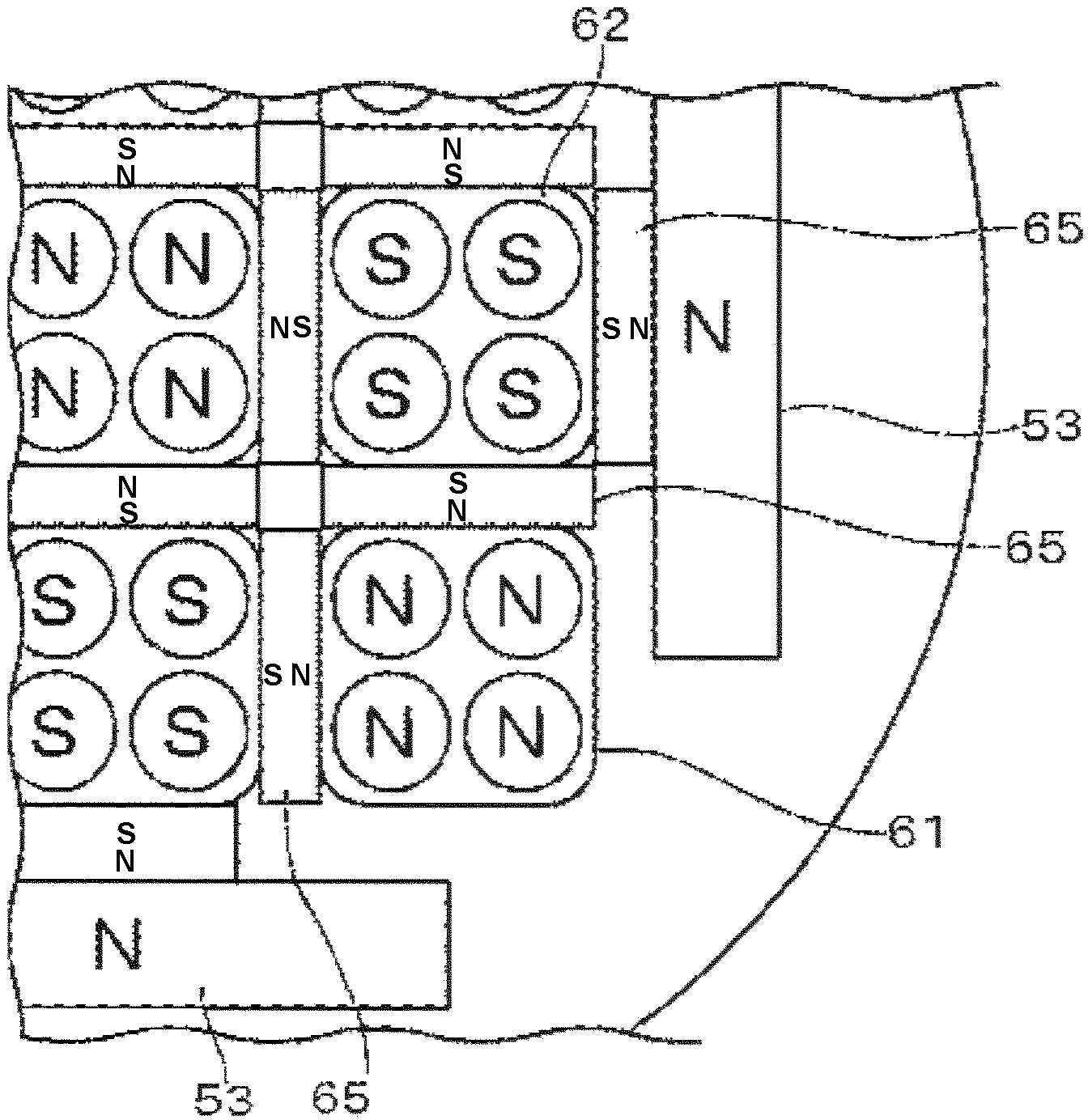

[0228] in having Figure 11 In the magnetron sputtering apparatus for the magnet array body 511, the film formation process was performed under the above-mentioned process conditions, and the relationship between the DC voltage applied to the target electrode 3 and the power density was evaluated. At this time, the distance between the target 31 and the wafer 10 was set to 30 mm. In addition, for the configuration in which the return magnet 531 is not provided in the magnet array body 511 (comparative example 1), Figure 23 The configuration (comparative example 2) using the conventional magnetron sputtering apparatus shown above and the configuration (comparative example 3) that discharges by applying a DC voltage without using a magnet were also evaluated in the same manner.

[0229] Figure 16 Indicates the result. In the figure, the horizontal axis represents the DC voltage applied to the target electrode 3, and the vertical axis represents the current density between t...

Embodiment 2)

[0232] in having figure 2 In the magnetron sputtering apparatus of the magnet array body 5, without rotating the magnet array body 5, the film-forming process was performed under the above-mentioned processing conditions, and the film-forming speed distribution in the wafer diameter direction was obtained. Also, for instead of figure 2 The magnet array body 5 is provided with Figure 10 In the case of the magnet array body 5A, the film formation rate was also measured in the same manner. For this result, Figure 17 Indicates the configuration in which the magnet array body 5 is provided, Figure 18 A configuration in which the magnet array body 5A is provided is shown.

[0233] Here, the difference between the magnet array body 5 and the magnet array body 5A is only the number of magnet units 63 constituting the magnets 61, 62, but it has been confirmed that by adjusting the number of magnet units 63, the radial direction of the wafer 10 can be changed. film-forming vel...

Embodiment 3)

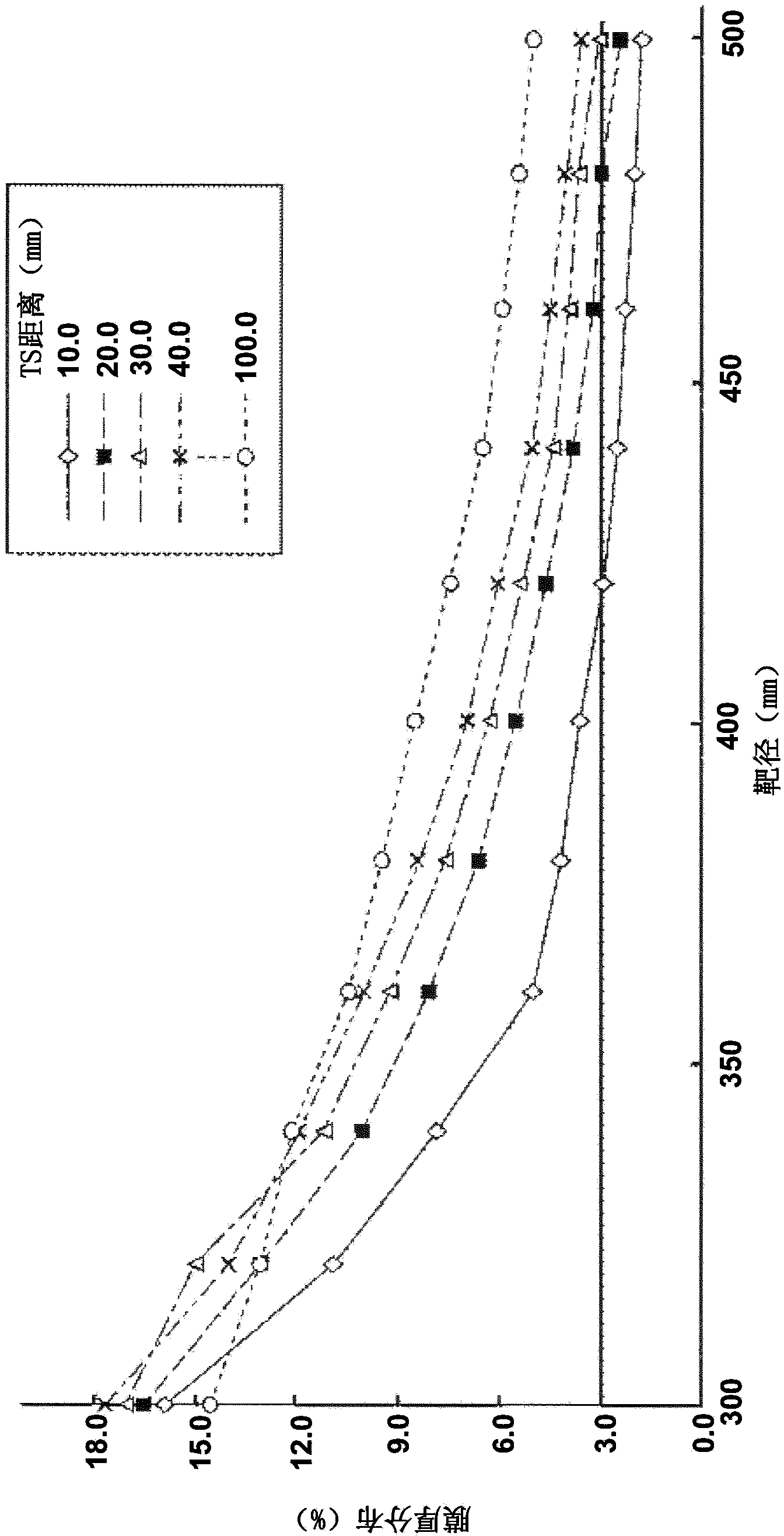

[0237] in having figure 2 In the magnetron sputtering of the magnet array body 5, the distance between the target 31 and the wafer 10 is set to 20mm, and the magnet array body 5 is not rotated, and the film formation process is performed under the above-mentioned processing conditions, and the Film formation velocity distribution in the radial direction of the wafer. In addition, the film formation rate was measured similarly also about the case where the distance between the target 31 and the wafer 10 was set to 50 mm. This result is shown together with the arrangement of the magnet group 5 of the magnet arrangement body 5 and the corrosion of the target 31 in Figure 19 . In addition, in this Example 3, the target 31 larger than the magnet group 52 of the magnet array body 5 was used.

[0238] From this, it can be confirmed that when the distance between the target 31 and the wafer 10 is 20 mm, the in-plane uniformity of the film formation rate is higher than when the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com