Preparation technology of polypeptide feed additive containing wheat or wheat processing products

A technology for processing products and polypeptide feed, applied in animal feed, animal feed, animal husbandry, etc., to achieve strong controllability, save production costs, and expand the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

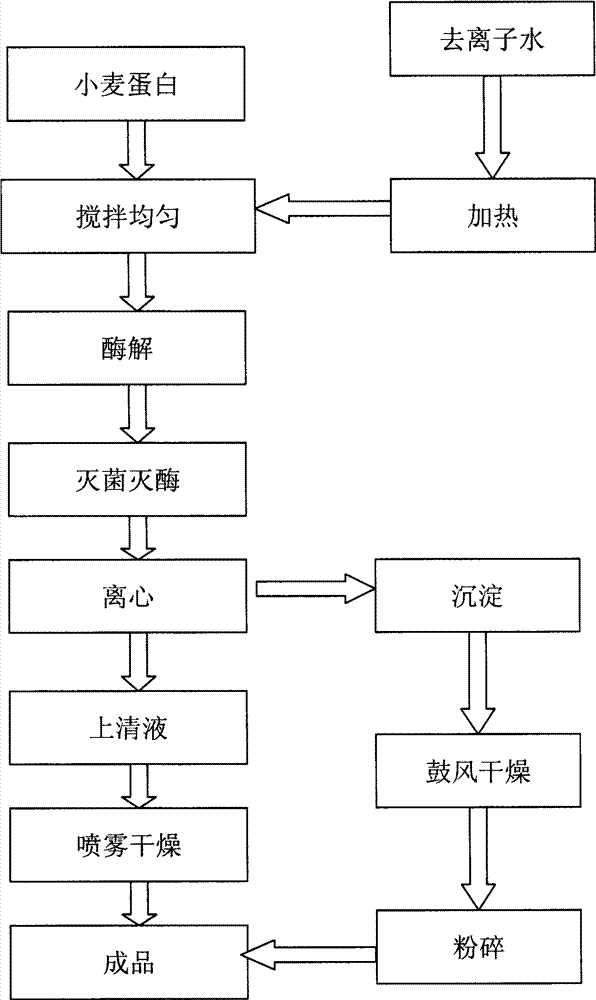

Method used

Image

Examples

Embodiment 1

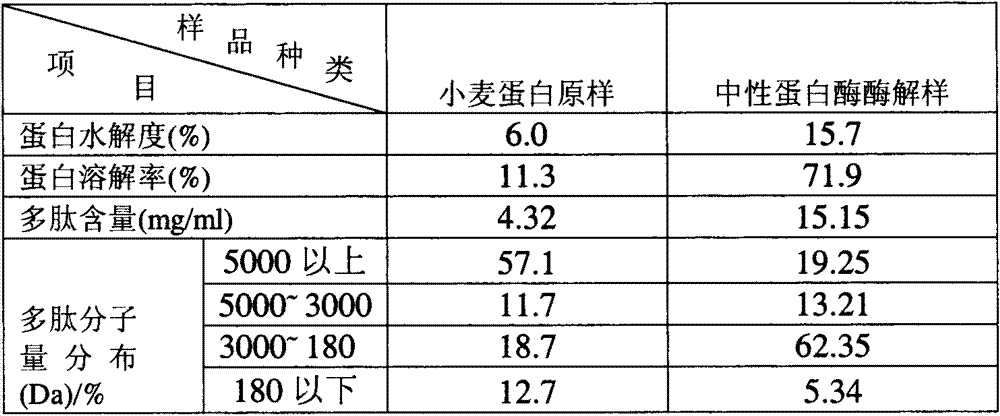

[0016] Example 1: Take 10 kg of wheat raw material, grind the raw material, add 80 L of deionized water, stir continuously while adding, and mechanically stir for 10 minutes at a speed of 1000 rpm, then transfer the material into the reactor without adjustment The pH of the reaction system, after the temperature rises to 45°C, add 10,000 U / g of substrate neutral protease, and react for 4 hours under these conditions. After the reaction is finished, the hydrolysis is stopped, and the enzymatic hydrolyzate product containing wheat polypeptide is obtained by centrifugal spray drying, which is added to the daily feed of suckling pigs in a ratio of 10% (weight ratio) instead of plasma protein.

Embodiment 2

[0017] Embodiment 2: Get 10kg of wheat flour, add 90L of deionized water, stir continuously while adding, and mechanically stir for 10 minutes at a rotating speed of 1000rpm, then transfer the material to the reactor without adjusting the pH of the reaction system, After the temperature rises to 50°C, add 10,000 U / g of substrate neutral protease, and react under these conditions for 3.5 hours. After the reaction is finished, the hydrolysis is stopped, and the enzymatic hydrolyzate product containing wheat polypeptide is obtained by centrifugal spray drying, which is added to the daily feed of suckling pigs at a ratio of 8% (weight ratio) instead of plasma protein.

Embodiment 3

[0018] Embodiment 3: Get 10kg of gluten powder, add 100L of deionized water, stir non-stop while adding, mechanically stir for 10 minutes at a rotating speed of 1000rpm, then transfer the material into the reactor without adjusting the pH of the reaction system , after the temperature rises to 50°C, add 10000U / g substrate neutral protease, and react under this condition for 3.5h. After the reaction is finished, the hydrolysis is stopped, and the enzymatic hydrolyzate product containing the polypeptide is obtained by centrifugal spray drying, which is added to the daily feed of suckling pigs in a ratio of 5% (weight ratio) instead of plasma protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com