Method for separating and recovering non-acidic oxygenated organic substances in Fischer-Tropsch synthesis reaction water

A Fischer-Tropsch synthesis, separation and recovery technology, applied in the separation/purification of carbonyl compounds, the preparation of organic compounds, organic chemistry, etc., can solve the problem of no effective recovery of aldehyde compounds, and achieve high recovery rate, simple method, improved economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

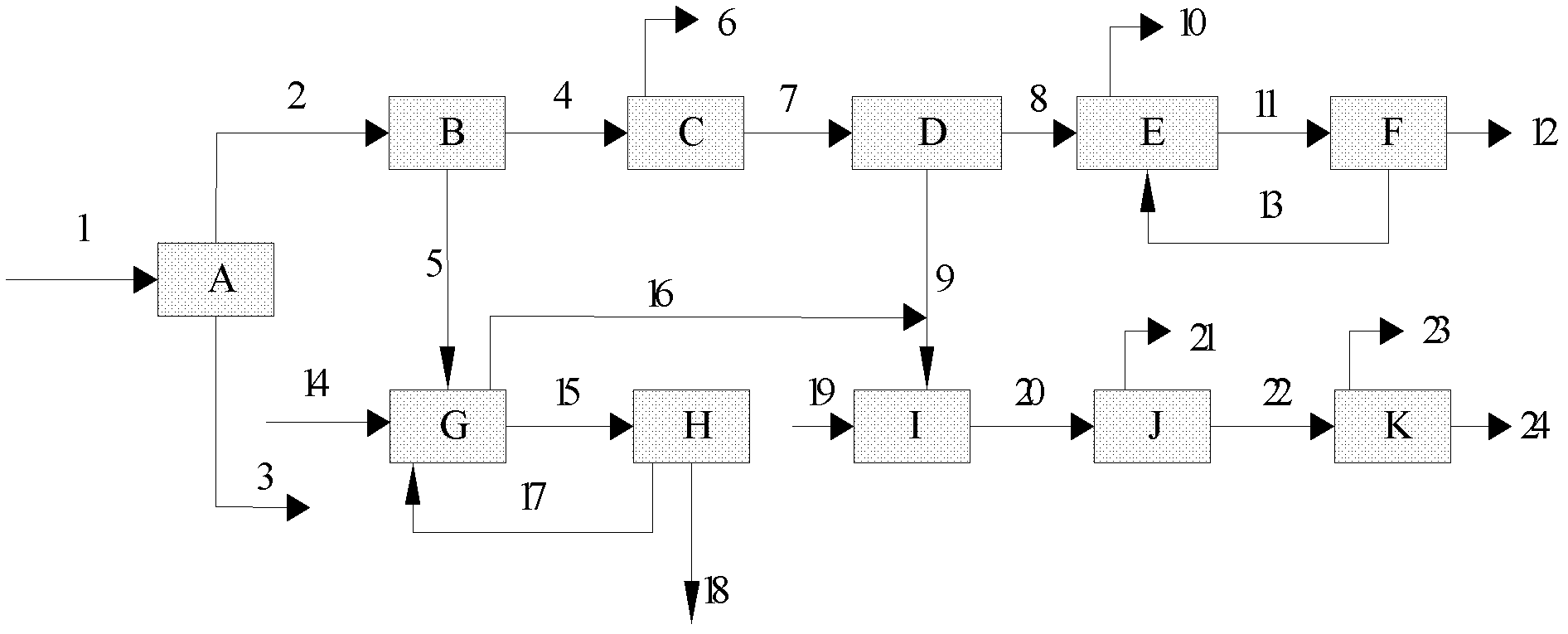

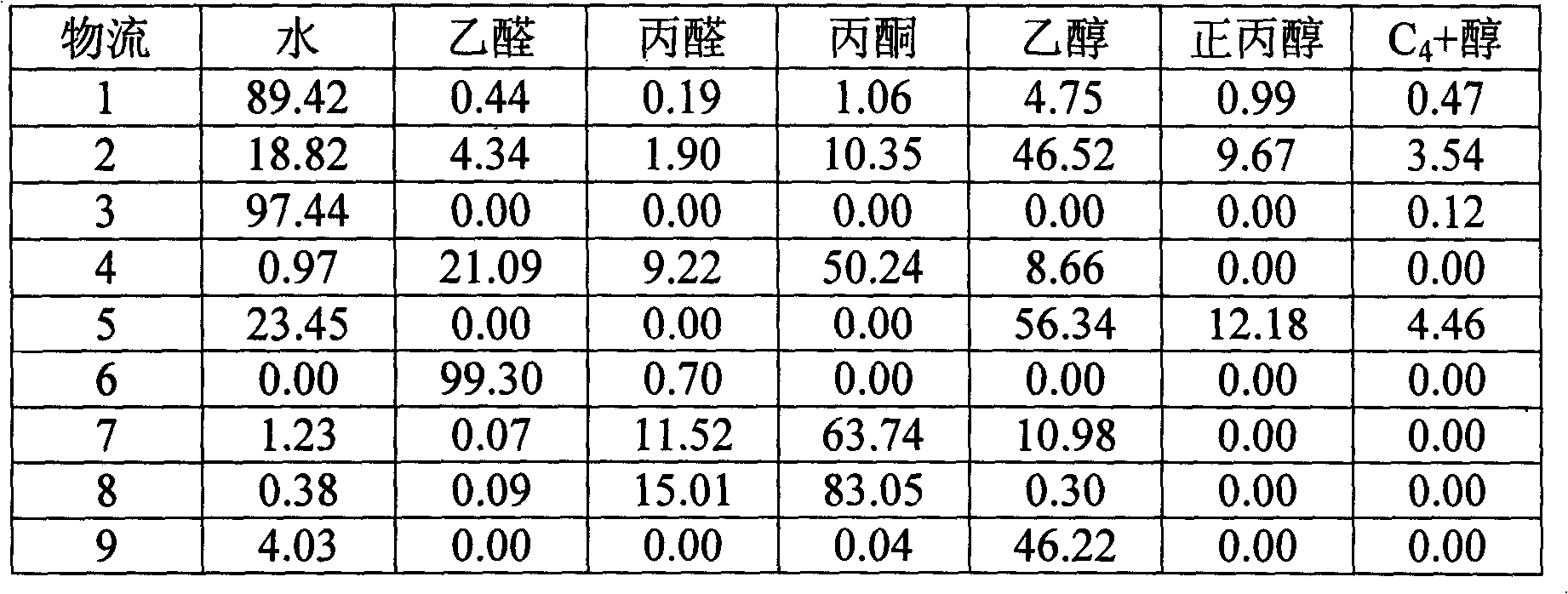

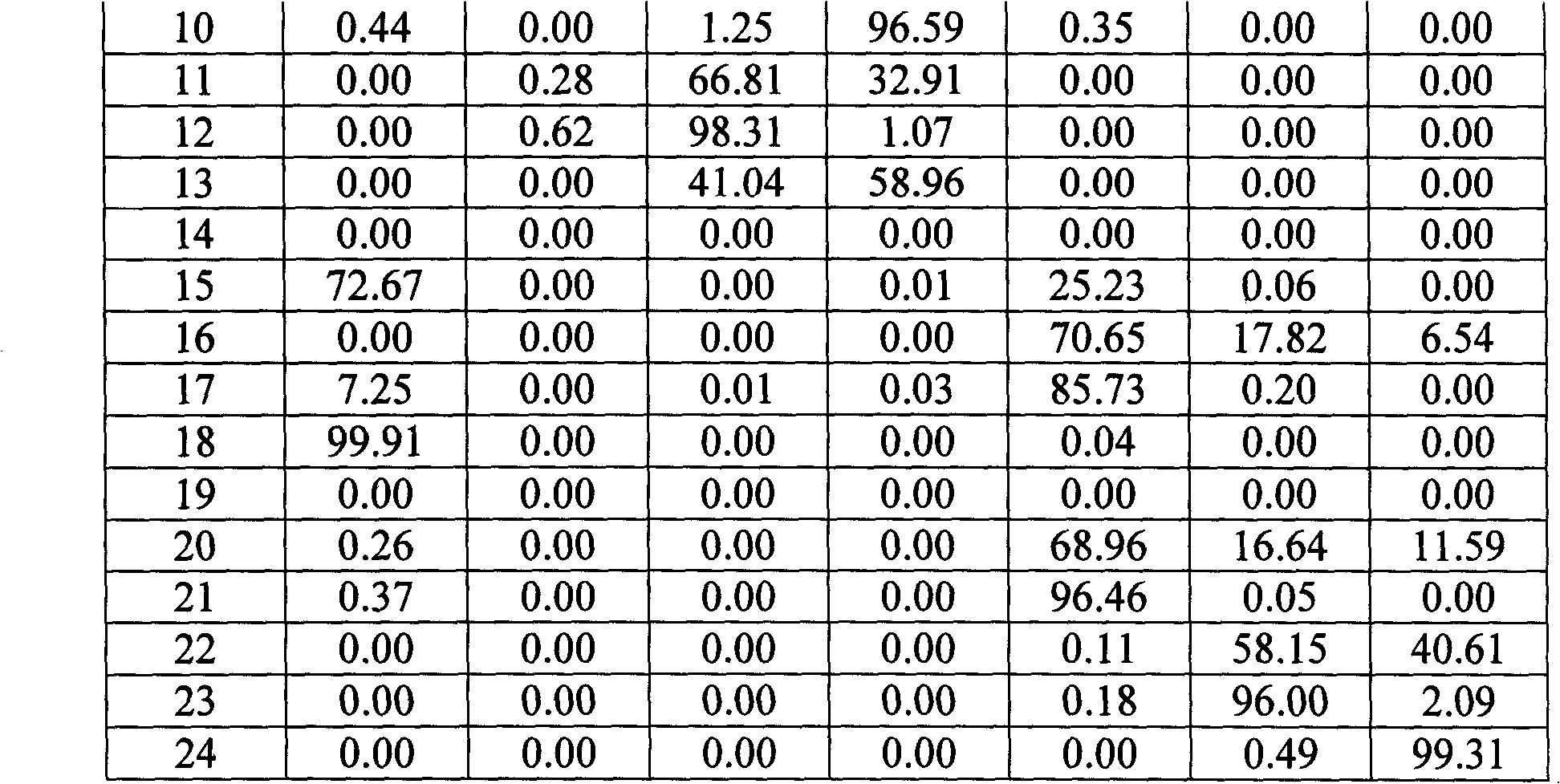

[0052] according to figure 1 As shown in the flow process, the Fischer-Tropsch synthesis reaction water flow 1 (see Table 1 for composition) enters the reaction water concentration rectification column A, the number of theoretical plates is 50, the reflux ratio is 2, and the feeding position is the 25th plate from the top. Control the temperature at the top of the tower to be 71.5°C to 72.5°C, and the temperature at the bottom of the tower to be at 99.3°C to 100.3°C. The output stream 2 at the top of the tower enters Tower B. The number of theoretical plates is 50. The ratio is 4, the temperature at the top of the tower is controlled at 47°C to 48°C, the temperature at the bottom of the tower is at 84°C to 85°C, the production liquid 4 at the top of the tower enters the acetaldehyde tower C, the number of theoretical plates is 50, and the feeding position is at the top Starting from the 25th block, the reflux ratio is 4, the temperature at the top of the tower is controlled at...

Embodiment 2

[0059] according to figure 1 As shown in the flow process, the Fischer-Tropsch synthesis reaction water flow 1 (see Table 2 for the composition) enters the reaction water concentration rectification column A, the number of theoretical plates is 20, the reflux ratio is 10, and the feed position is the 10th plate from the top, and the control The temperature at the top of the tower is 71.5°C to 72.5°C, the temperature at the bottom of the tower is 99.3°C to 100.3°C, the output stream 2 at the top of the tower enters tower B, the number of theoretical plates is 15, the feeding position is the seventh block from the top, and the reflux ratio is 10. Control the temperature at the top of the tower to 47°C-48°C, the temperature at the bottom of the tower to 84°C-85°C, the production liquid 4 at the top of the tower enters the acetaldehyde tower C, the number of theoretical plates is 15, and the feeding position is the first from the top 7 blocks, the reflux ratio is 10, the temperatu...

Embodiment 3

[0065] according to figure 1 As shown in the flow process, the organic composition of the Fischer-Tropsch synthesis reaction water flow 1 is changed, and the operating conditions of each tower are as follows. The Fischer-Tropsch synthesis reaction water flow 1 (see Table 3 for the composition) enters the reaction water concentration rectification tower A, and the number of theoretical plates is 35 , the reflux ratio is 6, the feeding position is the 17th plate from the top, the temperature at the top of the tower is controlled at 74°C to 75.5°C, the temperature at the bottom of the tower is at 99°C to 101°C, the stream 2 from the top of the tower enters tower B, and the theoretical tower The number of plates is 35, the feeding position is the 17th block from the top, the reflux ratio is 8, the temperature at the top of the tower is controlled at 52°C to 53°C, the temperature at the bottom of the tower is at 8.54°C to 86°C, and the production liquid 4 at the top of the tower ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com