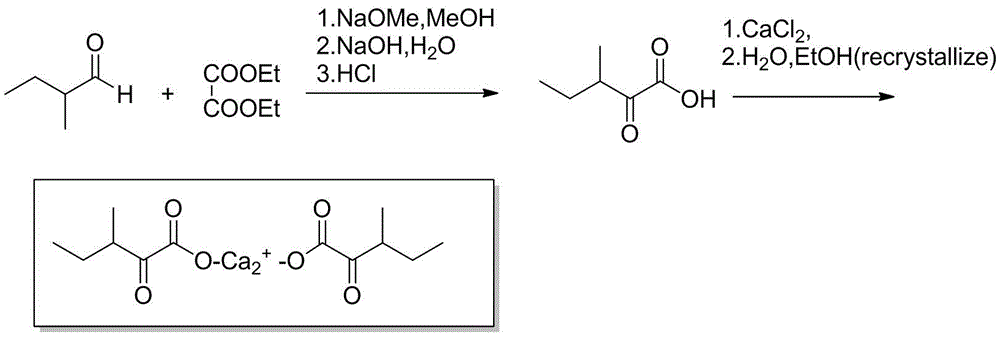

A kind of preparation method of racemic ketone calcium isoleucine

A technology of racemic ketone isoleucine calcium and sodium isopropoxide, which is applied in the field of drug synthesis, can solve the problems of high cost, large negative impact on the environment, and many reaction raw materials, and achieves simple operation, mild conditions, and low toxicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] At 25°C, drop 300kg of diethyl oxalate into 390kg of 28% sodium methoxide methanol solution, keep stirring for half an hour after dropping, add 200kg of 2-methylbutyraldehyde, keep warm for half an hour after adding, at a temperature not greater than 25°C Under certain conditions, add 30% sodium hydroxide aqueous solution, keep it warm for 5 hours after dripping, add 70kg of hydrochloric acid dropwise, stir for half an hour, add 600kg of methyl isobutyl ketone for extraction three times, add 100kg of purified water to the organic phase, and add 30% sodium hydroxide Aqueous solution to adjust the pH value to 5.8, layering, adding 30% sodium hydroxide aqueous solution to the organic phase to adjust the pH value to 5.8, layering, merging the aqueous phase, merging the aqueous phase, adding 30% sodium hydroxide aqueous solution to adjust the pH value to 8.8, Add 300kg of calcium chloride aqueous solution at no lower than 20°C, keep warm and stir for 2 hours after dripping, s...

Embodiment 2

[0033] At 25°C, drop 233.6 kg of dimethyl oxalate into 389 kg of 28% sodium ethoxide ethanol solution, keep stirring for half an hour after dropping, add 159 kg of 2-methylbutyraldehyde, keep warm for half an hour after adding, at a temperature not greater than 25°C Under certain conditions, add 30% sodium hydroxide aqueous solution, keep warm for 5 hours after dropping, add 58kg of hydrochloric acid dropwise, stir for half an hour, add 600kg of methyl isobutyl ketone for extraction three times, add 100kg of purified water to the organic phase, and add 30% sodium hydroxide Aqueous solution to adjust the pH value to 5.8, layering, adding 30% sodium hydroxide aqueous solution to the organic phase to adjust the pH value to 5.8, layering, merging the aqueous phase, adding 30% sodium hydroxide aqueous solution to adjust the pH value to 8.8, at least Add 232kg of calcium chloride aqueous solution at 20°C, keep stirring for 2 hours after dripping, slowly cool down to 5°C, keep warm fo...

Embodiment 3

[0035] Example 3: The difference between this example and Example 1 is that ammonia water is used instead of 30% sodium hydroxide aqueous solution to adjust the pH value, and 190 kg of refined dry product is obtained with a total yield of 81.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com