Method for performing solderability treatment on the surface of welding area while making solder resist pattern

A welding area and solderability technology, which is applied in the secondary treatment of printed circuits, coating of non-metallic protective layers, etc., can solve the requirements of more refined packaging structure of electronic components and the difficulty of welding fine-pitch components , not suitable for fine-pitch circuit boards, etc., to achieve the effect of reducing environmental burden, small site, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for performing solderability treatment on the surface of a welding zone while making a solder resist pattern, the steps of which are:

[0039] (1) Solder resist coating: Coat the entire board by screen printing, use 43T mesh to coat the photosensitive ink C-7 on the board, and let it stand for 10~20min after missing printing;

[0040] ⑵Solder resist curing: Put the plate after standing still in the drying oven to bake, and cure the photosensitive ink C-7 in two stages, after curing for 30 minutes at 75±2°C, and then curing for 70 minutes at 150°C;

[0041] (3) Data import: Import the data of the solder mask layer, process it with data processing software, obtain the laser processing path, and import the processing path into the laser equipment control software;

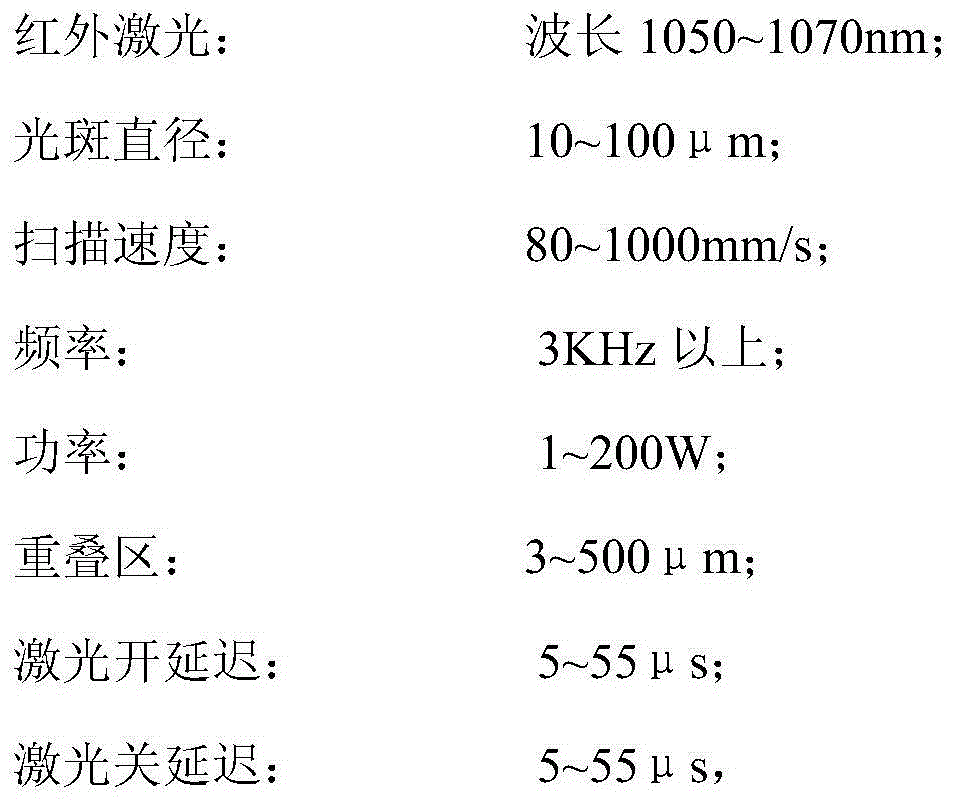

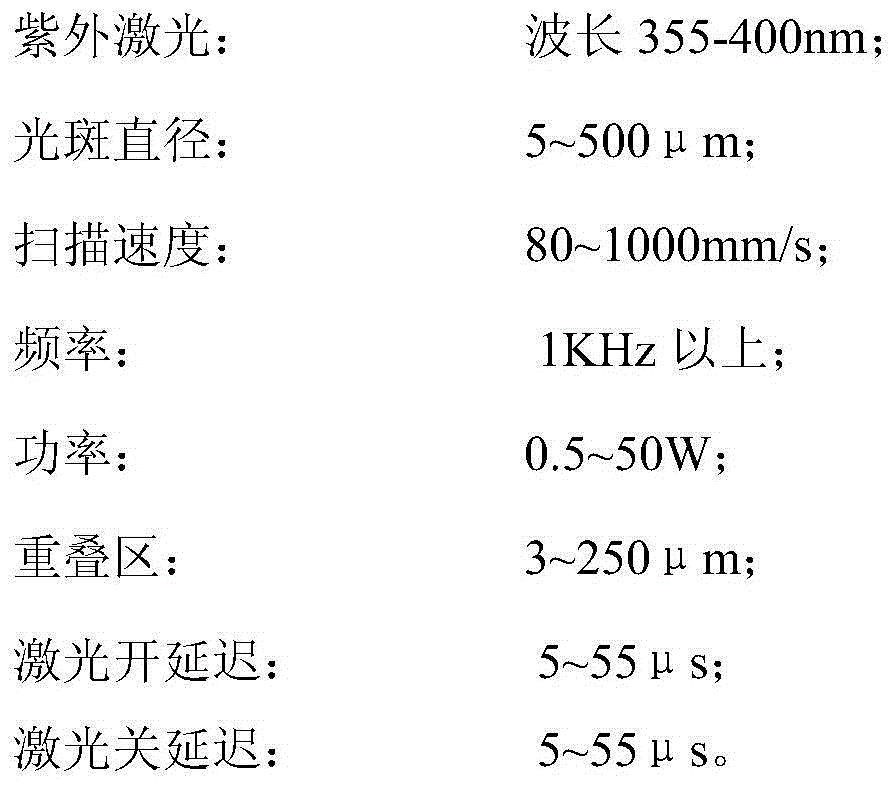

[0042] ⑷Laser photoetching: place the cured photosensitive ink C-7 on the laser equipment, and accurately align the top layer of the board with the processing path, and perform photoetching on the top ...

Embodiment 2

[0047] A method for performing solderability treatment on the surface of a welding zone while making a solder resist pattern, the steps of which are:

[0048] (1) Solder resist coating: Coat the entire board by screen printing, use 43T mesh to coat the photosensitive ink UPC-9000 on the board, and let it stand for 10~20 minutes after missing printing;

[0049] ⑵Solder resist curing: Put the plate after standing still in the drying oven to bake, and cure the photosensitive ink UPC-9000 in two stages, after curing for 50 minutes at 67±2°C, and then curing for 60 minutes at 150°C;

[0050] (3) Data import: Import the data of the solder mask layer, process it with data processing software, obtain the laser processing path, and import the processing path into the laser equipment control software;

[0051] ⑷Laser photoetching: Place the in-process panel after the photosensitive ink UPC-9000 is cured on the laser equipment, accurately align the top layer of the in-process panel with ...

Embodiment 3

[0056] A method for performing solderability treatment on the surface of a welding zone while making a solder resist pattern, the steps of which are:

[0057] (1) Solder resist coating: Coat the entire board by screen printing, use 43T mesh to coat the photosensitive ink VSR-ZG on the board, and let it stand for 10~20min after missing printing;

[0058] ⑵Solder resist curing: put the board after standing still into the UV curing equipment to cure the photosensitive ink VSR-ZG, the light energy density is 12μW / cm2, and the transmission speed of the board is 1.5-2.0m / min;

[0059] (3) Data import: Import the data of the solder mask layer, process it with data processing software, obtain the laser processing path, and import the processing path into the laser equipment control software;

[0060] ⑷Laser photoetching: place the cured photosensitive ink VSR-ZG on the laser equipment, align the top layer of the board with the processing path accurately, and perform photoetching on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com