Method for preparing calcium chloride from high-alkalinity calcium solution and extracted hydrochloric acid in epoxypropane production

A technology of propylene oxide and high alkalinity, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problem of low yield of propylene oxide, low utilization rate of hydrochloric acid, large heat consumption, etc. problems, to achieve the effect of environmental protection, high concentration and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

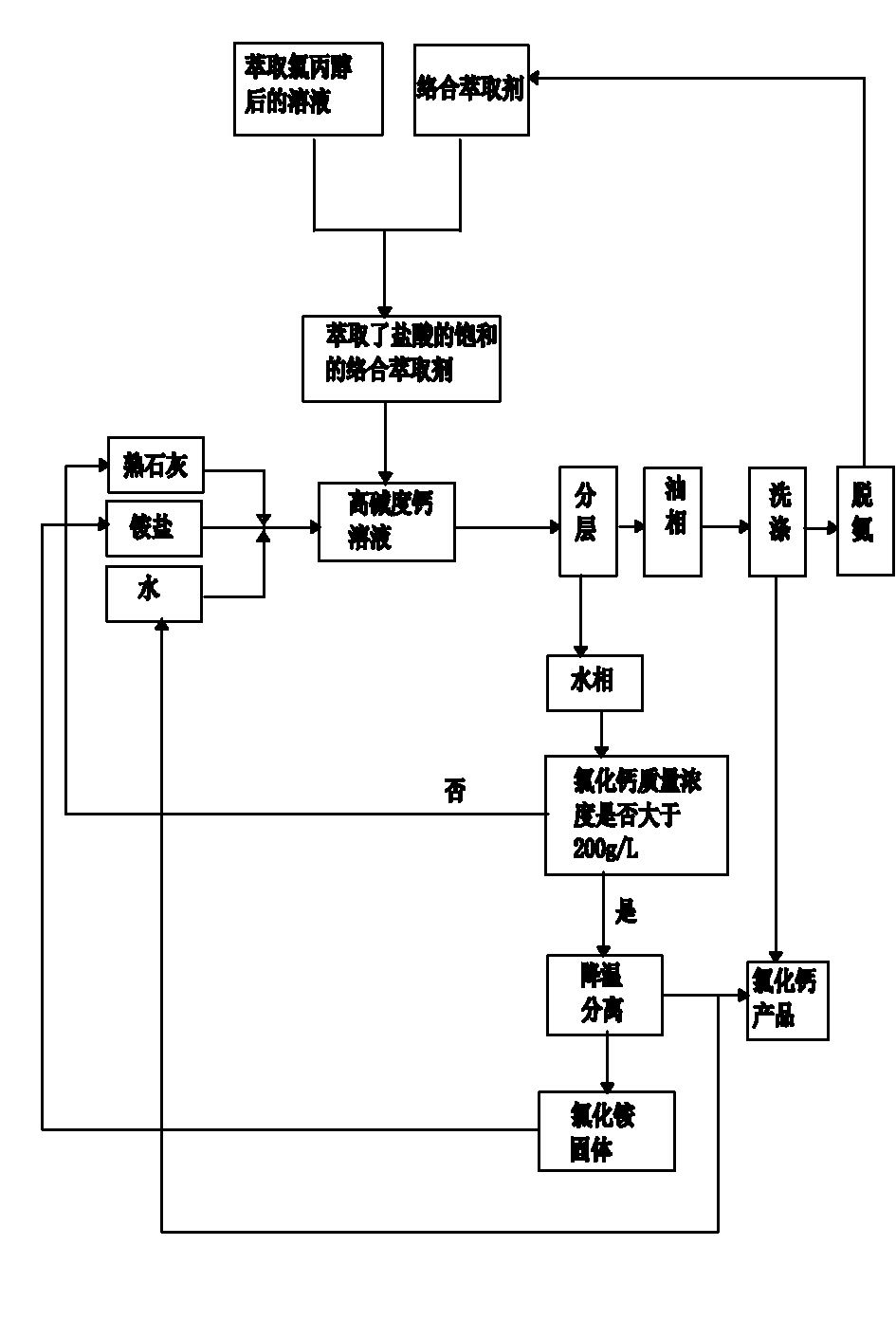

Image

Examples

Embodiment 1

[0033] A method for preparing calcium chloride from a high alkalinity calcium solution and extracted hydrochloric acid in the production of propylene oxide, comprising the following process steps:

[0034] 1) Chloroalcoholization reaction: react chlorine gas, propylene and water, the content of chloropropanol produced is about 4%, and the content of hydrochloric acid is about 1.6%;

[0035] 2) Extraction of chloropropanol: After extracting the chloropropanol obtained in step 1) with an extractant, enter the saponification process to produce propylene oxide;

[0036] 3) Extraction of hydrochloric acid: fully extract the hydrochloric acid in the solution after extracting chloropropanol in step 2) with a complex extractant, which is composed of n-trioctylamine, n-tetradecane and tributyl phosphate It is mixed at a volume ratio of 50:45:5, and the extraction temperature is 80°C. The so-called full extraction means that the extracted hydrochloric acid is saturated, and the extracti...

Embodiment 2

[0043] The difference with embodiment 1 is:

[0044] 1) The blending agent in the complexing extractant is n-octanol instead of tributyl phosphate in Example 1, and the volume ratio of solvent, complexing agent and blending agent is 70:25:5;

[0045] 2) In step 4), lime is used instead of slaked lime, ammonium chloride solution with a concentration of about 3mol / L is selected, and the alkalinity of the prepared high-alkalinity calcium solution is 2.25mol / L, and the preparation temperature is 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com