Environment-friendly ecological full-nutrient fertilizer and production method of environment-friendly ecological full-nutrient fertilizer

A fully nutritious and ecological technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of insignificant increase in yield and low fertilizer utilization rate, and achieve significant increase in yield, easy absorption and utilization, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Formula: 175 kg of urea, 200 kg of ammonium sulfate, 375 kg of monoammonium phosphate, 125 kg of potassium chloride, 50 kg of wheat straw ash, 10 kg of compound amino acid, activated carbon source (mixture of glucose and vitamin C at a weight ratio of 1:1) 4 kg, 80 kg of bentonite.

[0027] production method:

[0028] A. Put the urea, ammonium sulfate, monoammonium phosphate, potassium chloride, wheat straw ash, compound amino acid, and active carbon source in the formula into the mixing equipment according to the proportion, and mix well;

[0029] B. After the mixed material is crushed (the diameter of the material particle is less than 40 mesh), it is transported to the granulator for granulation;

[0030] C. After drying, cooling, screening (controlling the particle diameter of the fertilizer product within the range of 2.0-4.5cm), metering and packaging, the green ecological full-nutrient fertilizer is obtained.

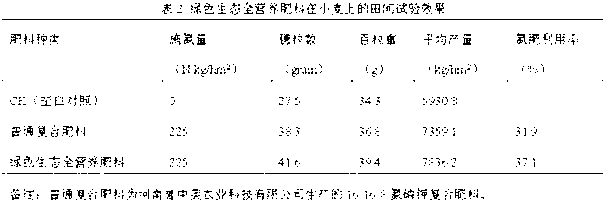

[0031] The green ecological full-nutrition fert...

Embodiment 2

[0034] Formula: 460 kg of urea, 110 kg of ammonium sulfate, 180 kg of monoammonium phosphate, 110 kg of potassium sulfate, 60 kg of corn stalk ash, 50 kg of compound amino acid, 1 kg of activated carbon source (glucose and vitamin C in a weight ratio of 1:3) , 60 kg of kaolin.

[0035] Production method is with embodiment 1.

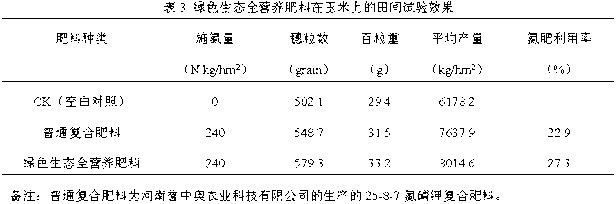

[0036] The green ecological full-nutrition fertilizer produced in this example was used as a base fertilizer and applied to corn. See Table 3 for the field test.

[0037]

[0038] From the field test results in Table 2 and Table 3, it can be seen that compared with ordinary compound fertilizers, the green ecological full-nutrition fertilizer of the present invention has a significant effect on increasing production, and (in terms of nitrogen fertilizer) improves the utilization rate of fertilizers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com