Production method of high-purity sodium dodecyl sulfate

A technology of sodium lauryl sulfate and a production method, which is applied in the direction of sulfuric acid ester preparation, chemical instruments and methods, sulfonic acid preparation, etc., can solve the problems of low product purity, high impurity content, and restricting the scope of use of the product, and achieve no The effect of three waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

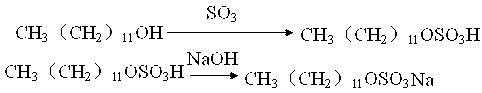

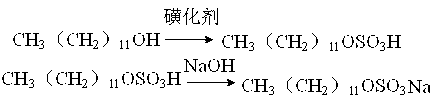

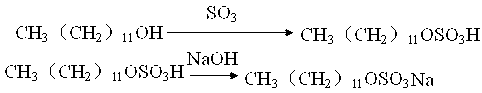

[0017] The production method of the high-purity sodium lauryl sulfate of the present embodiment, its steps are:

[0018] (1) Sulfonation and neutralization: Add 116.52kg of chlorosulfonic acid liquid to 190.18kg of lauryl alcohol (98.1% by mass) for sulfonation reaction to generate sulfuric acid ester (CH 3 (CH 2 ) 11 OSO 3 H), sulfuric acid ester and 118kg mass percentage concentration are that the NaOH of 34% produces neutralization reaction and obtains liquid sodium lauryl sulfate, after measuring the mass percent of sodium lauryl sulfate in this liquid sodium lauryl sulfate The concentration is 38%, 177kg;

[0019] (2) Concentration, crystallization and purification, and solid-liquid separation: Concentrate the liquid sodium lauryl sulfate and precipitate 295kg of solid material in the form of crystal sequins. The mass fraction of sodium lauryl sulfate in the solid material is 60%. The weight moisture content of the material is 39%;

[0020] (3) Low-temperature drying...

Embodiment 2

[0025] The production method of the high-purity sodium lauryl sulfate of the present embodiment, its steps are:

[0026] (1) Sulfonation and neutralization: Add 82.5kg of sulfur trioxide gas to 188.26kg of lauryl alcohol (99% by mass) to generate sulfuric acid ester (CH 3 (CH 2 ) 11 OSO 3 H), sulfuric acid ester and 200kg mass percent concentration are the NaOH of 20% to generate neutralization reaction to obtain liquid sodium lauryl sulfate, after measuring the mass percentage of sodium lauryl sulfate in this liquid sodium lauryl sulfate The concentration is 10%, 42.48kg;

[0027] (2) Concentration, crystallization purification, and solid-liquid separation: Concentrate the liquid sodium lauryl sulfate and precipitate 49.97kg of solid material in the form of crystal sequins. The mass fraction of sodium lauryl sulfate in the solid material is 85%. The weight moisture content of the solid material is 13.1%;

[0028] (3) Low-temperature drying: dry the concentrated solid mat...

Embodiment 3

[0033] The production method of the high-purity sodium lauryl sulfate of the present embodiment, its steps are:

[0034] (1) Sulfonation and neutralization: Add 96kg of sulfur trioxide gas to 187.32kg of lauryl alcohol (99.5% by mass) to generate sulfuric acid ester (CH 3 (CH 2 ) 11 OSO 3 H), sulfuric acid ester and 150kg mass percent concentration are the NaOH of 27% to generate neutralization reaction to obtain liquid sodium lauryl sulfate, after measuring the mass percentage of sodium lauryl sulfate in this liquid sodium lauryl sulfate The concentration is 19%, 80.54kg;

[0035] (2) Concentration, crystallization purification, solid-liquid separation: Concentrate the liquid sodium lauryl sulfate, and precipitate 111.86kg of solid material in the form of crystal sequins. The mass fraction of sodium lauryl sulfate in the solid material is 72%. The weight water content of the solid material is 27.5%;

[0036] (3) Low-temperature drying: dry the concentrated solid material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com