Adhesive composition, adhesive and adhesive sheet

A technology of composition and adhesion, applied in the direction of adhesive type, ester copolymer adhesive, polyurea/polyurethane adhesive, etc., can solve insufficient reusability, insufficient stress relaxation rate, adhesion Eliminate problems such as increased strength, and achieve the effects of good reusability, excellent durability, and excellent cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] 1. Preparation of polymer (A)

[0128] Into a reaction vessel equipped with a stirrer, a thermometer, a reflux cooler, a dropping device, and a nitrogen introduction tube, 99.0 parts by mass of n-butyl acrylate, 1.0 part by mass of 2-hydroxyethyl acrylate, 200 parts by mass of ethyl acetate, and 2 parts were added. , 0.08 parts by mass of 2'-azobisisobutyronitrile, and replace the air in the reaction vessel with nitrogen. While stirring in this nitrogen atmosphere, the reaction solution was heated up to 60°C, and after the reaction was performed for 16 hours, it was cooled to room temperature. Here, a part of the obtained solution was subjected to molecular weight measurement by the following method, and the production of polymer (A) with a weight average molecular weight of 1.57 million was confirmed.

[0129] 2. Preparation of polymer (B)

[0130] Into a reaction vessel equipped with a stirrer, a thermometer, a reflux cooler, a dropping device, and a nitrogen introduction ...

Embodiment 2-11

[0151] (Example 2-11, Comparative Example 1-3)

[0152] Except that the types and ratios of the monomers of the adhesive composition, the types and blending amounts of crosslinking agent and silane coupling agent, and the blending ratio of polymer (A) and polymer (B) are changed as shown in Table 1. Except for the above, in the same manner as in Example 1, a polarizing plate having an adhesive layer was produced.

[0153] Here, the above-mentioned weight average molecular weight (Mw) is a weight average molecular weight in terms of polystyrene measured by gel permeation chromatography (GPC) under the following conditions (GPC measurement).

[0154]

[0155] ·GPC measuring device: made by TOSOH, HLC-8020

[0156] ·GPC column (pass in the following order): made by TOSOH

[0157] TSK guard co1umN HXL-H

[0158] TSK gel GMHXL(×2)

[0159] TSK ge1 G2000HXL

[0160] ·Measuring solvent: tetrahydrofuran

[0161] ·Measurement temperature: 40℃

experiment example 1

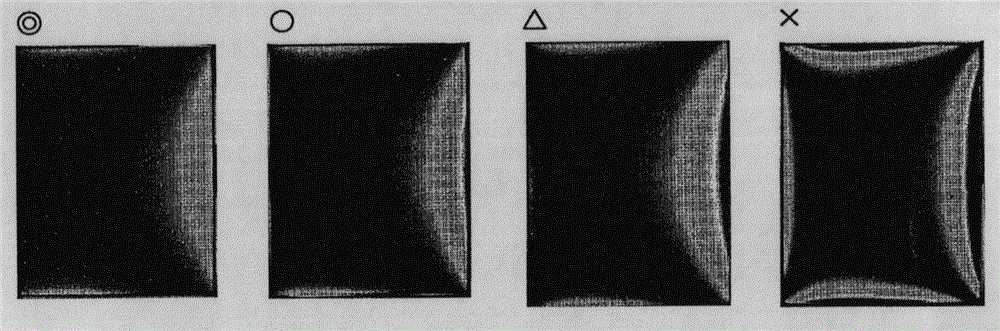

[0162] [Experiment example 1] (Light leakage experiment)

[0163] The polarizing plate with the adhesive layer obtained in the example or the comparative example was adjusted to a size of 233 mm×309 mm with a cutting device (Super Knife manufactured by Kono Seisakusho Co., Ltd., PN1-600). The peeling sheet is peeled off, and the exposed adhesive layer is attached to alkali-free glass (Corning, Eagle XG), and then pressurized in a kettle made by Kurihara Manufacturing Co., Ltd. at 0.5 MPa and 50°C for 20 minutes . In addition, in the bonding, the polarizing plate with the adhesive layer should be in a Nicol cross state (polarization axis: ∠45°, ∠135°). In this state, it was left in a dry environment at 80°C for 250 hours, and then left in an environment of 23°C and 50% RH for 2 hours. This was used as a sample and the light leakage was evaluated by the method shown below. The results are shown in Table 2.

[0164]

[0165] The sample was placed on a flat panel illuminator (manufa...

PUM

| Property | Measurement | Unit |

|---|---|---|

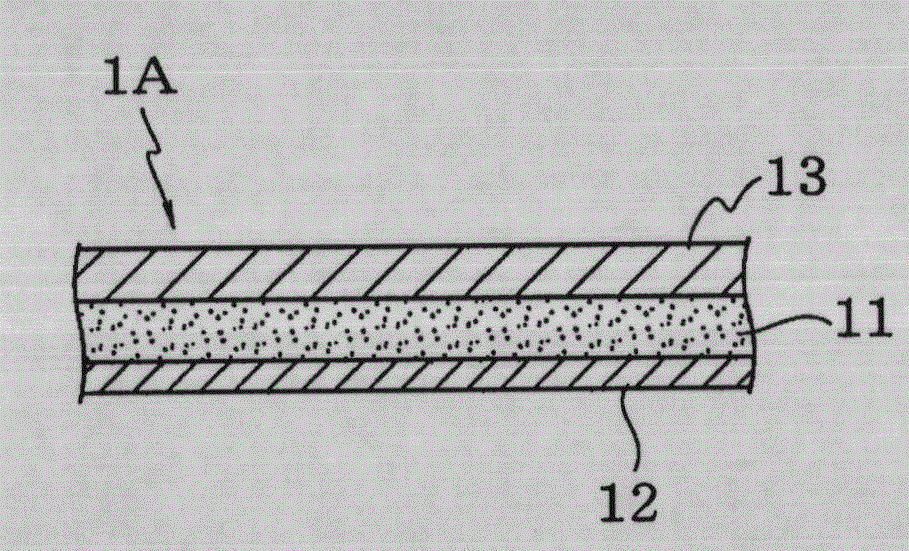

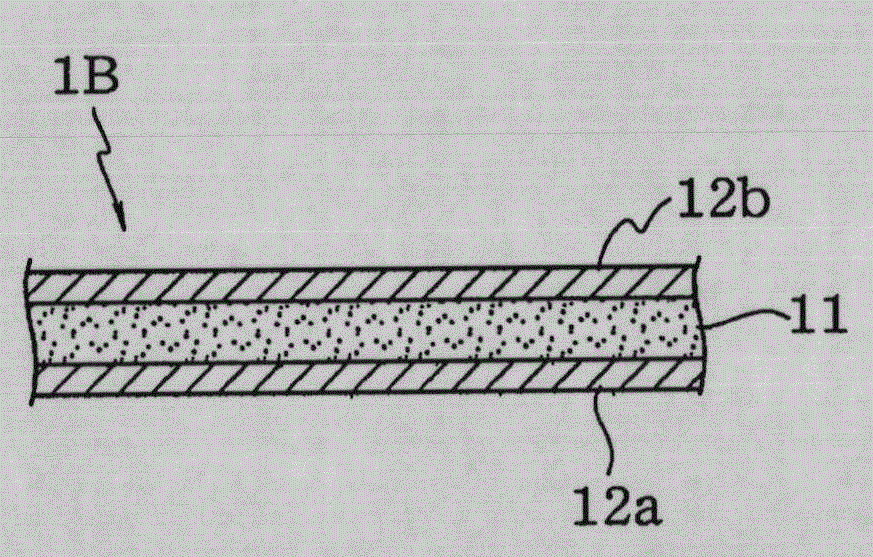

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com