Comprehensive recovery technology of valuable components in corundum smelting smoke ash containing gallium and potassium

A soot and corundum technology, applied in aluminum hydroxide and potassium sulfate waste, treatment of corundum smelting soot, and low-cost recovery of gallium metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

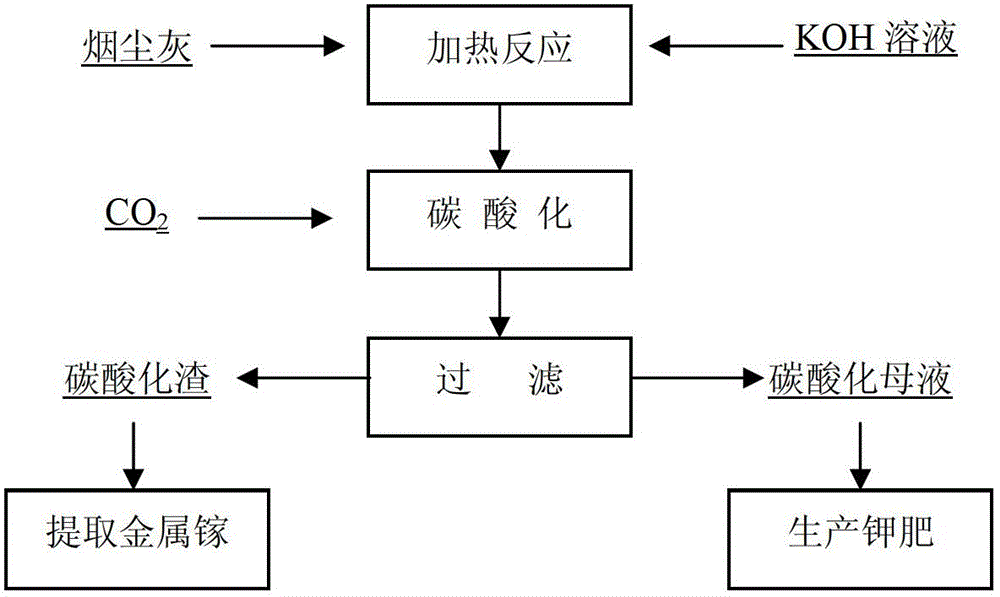

[0032] A full-process process for efficiently recovering gallium metal from corundum soot and extracting aluminum hydroxide and potash fertilizer.

[0033] The first step is to pretreat the soot, the process flow is shown in the attached figure 1 . The specific implementation method of pretreatment is: according to the liquid-solid ratio of 5:1~2:1, add soot and ash to the potassium hydroxide solution with a concentration of 10%~40%, and react at a temperature of 100~200°C for 1~3h , and then pass carbon dioxide into the reacted solution at a temperature of 75-95° C. to make the pH of the solution <9, and then filter to obtain the carbonated mother liquor and carbonated slag.

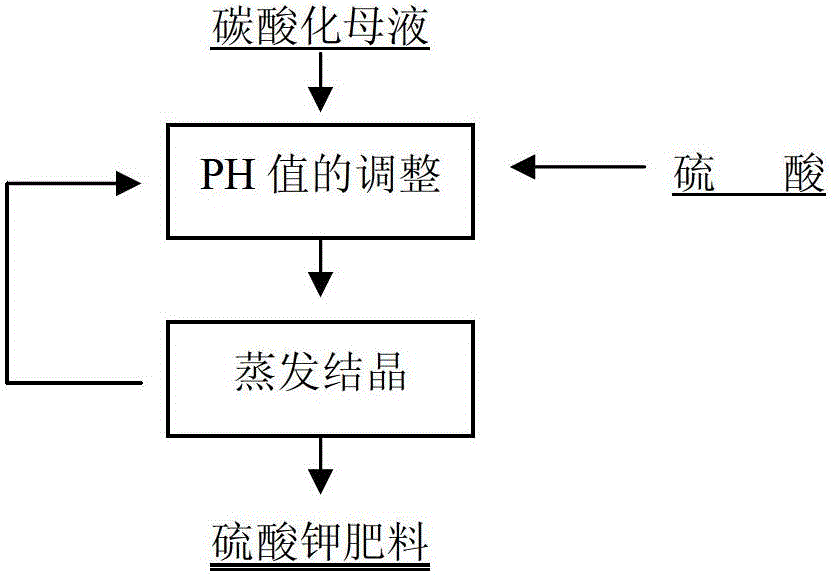

[0034] The second step is to use the carbonated mother liquor obtained in the first step as a raw material to produce potassium sulfate fertilizer. The process flow is shown in the attached figure 2 . The specific implementation of this step is as follows: add sulfuric acid to the carbonation mother...

Embodiment 2

[0045] Example 2: Efficient leaching of gallium in corundum soot

[0046] The concrete steps of this embodiment are as follows:

[0047] ① Prepare a potassium hydroxide solution with a concentration of 10%, add corundum soot at a liquid-solid ratio of 5:1, react at 200°C for 1 hour, and then pass carbon dioxide into the reacted solution at a temperature of 95°C to make the pH of the solution reach After 8.5, filter to obtain carbonated slag;

[0048] ②At room temperature, treat the carbonated slag with 1M sulfuric acid at a liquid-solid ratio of 3:1 for 0.5 hours and then filter to obtain high-silicon slag and pickling solution.

[0049] Through analysis, it is found that the process of this embodiment can realize 92% gallium in the corundum soot.

Embodiment 3

[0050] Example 3: Efficient comprehensive recovery of gallium, aluminum and potassium in corundum soot

[0051] The concrete steps of this embodiment are as follows:

[0052] The first step is to prepare a potassium hydroxide solution with a concentration of 40%, add corundum soot according to the liquid-solid ratio of 2:1, react at 100°C for 3 hours, and then pass carbon dioxide into the reacted solution at 75°C to make After the pH of the solution reached 8.8, it was filtered to obtain carbonated slag and carbonated slag. ;

[0053] In the second step, sulfuric acid is added to the carbonation mother liquor to make the pH value of the filtrate reach 6, and then evaporate and crystallize to obtain potassium sulfate fertilizer.

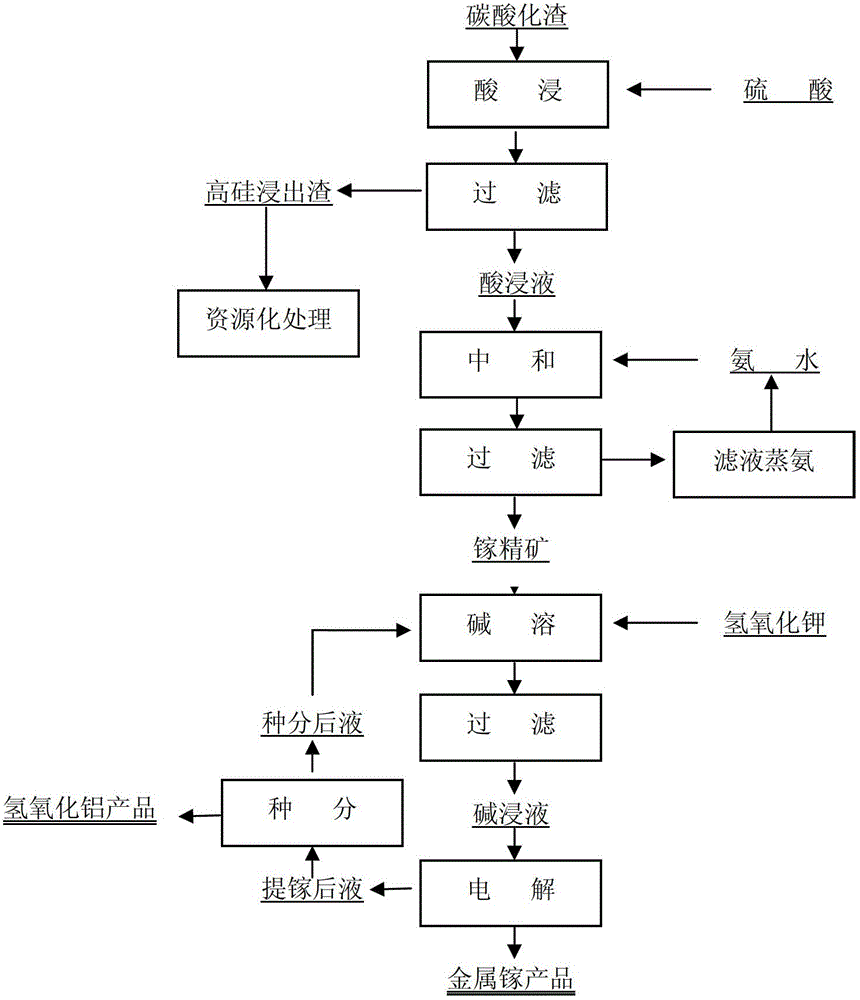

[0054] The third step is to reclaim gallium and aluminum from the carbonated slag obtained in the first step, and the specific implementation of this step is as follows:

[0055] 1. At room temperature, according to the liquid-solid ratio of 5:1, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com