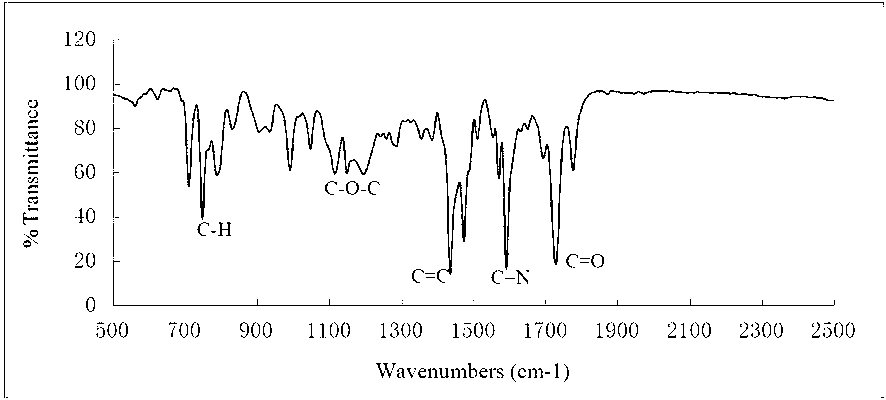

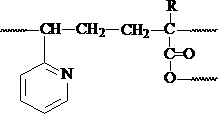

Pyridinium group-containing moderate-polarity skeleton adsorption resin and preparation method thereof

A technology of pyridine group and adsorption resin, which is applied to the field of polar skeleton adsorption resin containing pyridine group and its preparation field, and achieves the effects of high monomer conversion rate, cheap raw materials and easy regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

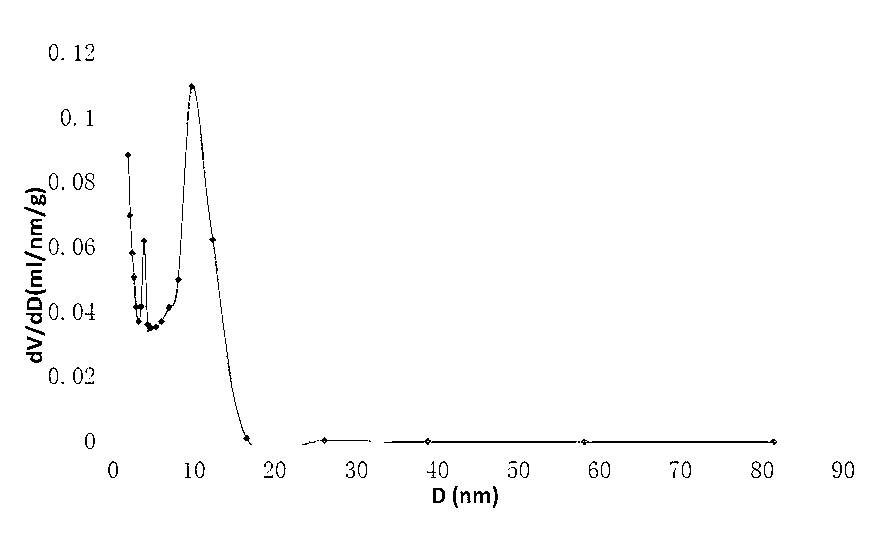

Method used

Image

Examples

Embodiment 1

[0027] In a 2000ml four-neck flask, add 550g of deionized water, 3.2g of gelatin, and 60g of NaCl, stir and heat to 35°C until the gelatin and NaCl are completely dissolved, then turn off the stirring and let stand for 5 minutes. Mix 60g of 2-vinylpyridine, 135g of diethylene glycol dimethacrylate, 4g of divinylbenzene (80% by mass), 1g of pentanethiol, 380g of toluene, and 1.3g of azobisisobutyronitrile , into the four-neck flask. Purge with nitrogen for 5 minutes, turn off the nitrogen, and start stirring at a stirring speed of 175 rpm. After the organic phase is dispersed into oil droplets with a particle size of 300-900 μm in the water phase, the temperature is raised to 55°C, and the reaction is continued for 2 hours. The temperature was raised to 70°C, and the reaction was carried out for 4 hours, and then the temperature was raised to 85°C, and the reaction was carried out for 8 hours. Heating was stopped and stirring was maintained until the temperature dropped to roo...

Embodiment 2

[0030] In a 1000ml four-neck flask, add 330g of deionized water, 1.8g of hydroxyethyl cellulose, and 30g of NaCl, stir and heat to 50°C until the hydroxyethyl cellulose and NaCl are completely dissolved, then turn off the stirring and let stand for 5 minutes. After mixing 40g of 2-vinylpyridine, 50g of diethylene glycol dimethacrylate, 9g of divinylbenzene (80% by mass), 200g of xylene, and 1.1g of azobisisobutyronitrile, add four in the flask. Purge nitrogen for 5 minutes, turn off nitrogen, and start stirring at a stirring speed of 175 rpm. After the organic phase is dispersed into oil droplets with a particle size of 300-900 μm in the water phase, the temperature is raised to 55°C, and the reaction is continued for 3 hours. The temperature was raised to 70°C, and the reaction was carried out for 4 hours, and then the temperature was raised to 85°C, and the reaction was carried out for 6 hours. Heating was stopped and stirring was maintained until the temperature dropped to...

Embodiment 3

[0033] In a 2000ml four-neck flask, add 445g deionized water, 0.5g methyl hydroxypropyl cellulose, 2.5g gelatin, 0.5g polyvinyl alcohol, 1.5g hydroxyethyl cellulose, 50g NaCl, stir and heat to 55 ℃, until completely dissolved, turn off the stirring and let it stand for 5 minutes. 36g of 2-vinylpyridine, 140g of allyl methacrylate, 3.5g of divinylbenzene (80% by mass), 760g of xylene, and 1.9g of azobisisobutyronitrile were mixed evenly, and then added to a four-necked flask. Purge nitrogen for 5 minutes, turn off nitrogen, and start stirring at a stirring speed of 175 rpm. After the organic phase is dispersed into a suitable particle size in the water phase, heat up to 55°C, react for 2 hours, and continue to heat up to 70°C. React for 6 hours, then raise the temperature to 85°C, and react for 5 hours. Heating was stopped and stirring was maintained until the temperature dropped to room temperature. Then continue to heat up, steam out xylene, wash and discharge. Vacuum-dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com